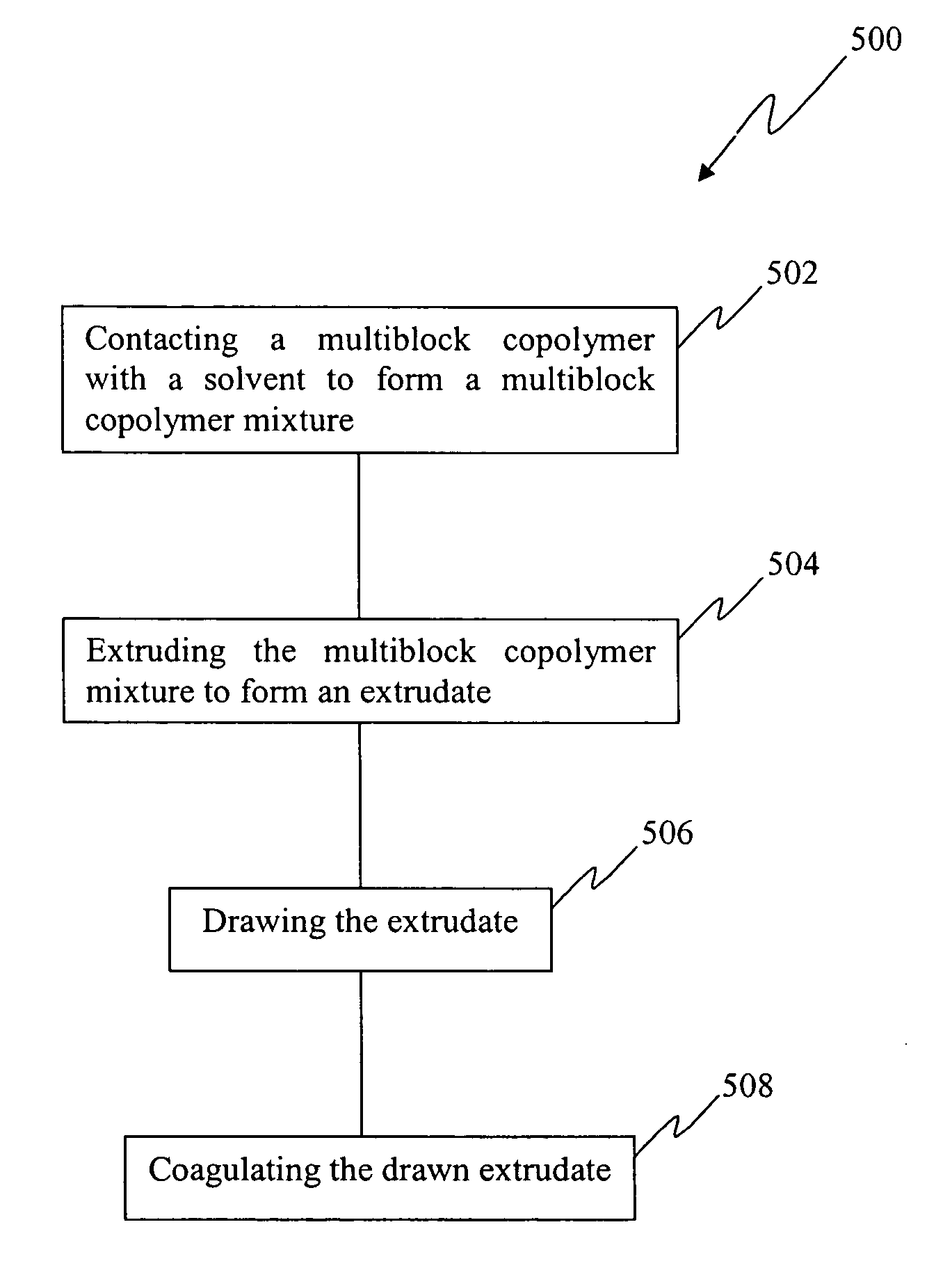

Process for producing a hyper-elastic, high strength dilatation balloon made from multi-block copolymers

a copolymer and high-strength technology, applied in the field of balloons, can solve the problems of stenosis that requires treatment, polymer materials with a relatively low yield point, and follow the original stress-strain curve, and achieve high elastic recovery, low profile, and high hoop strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

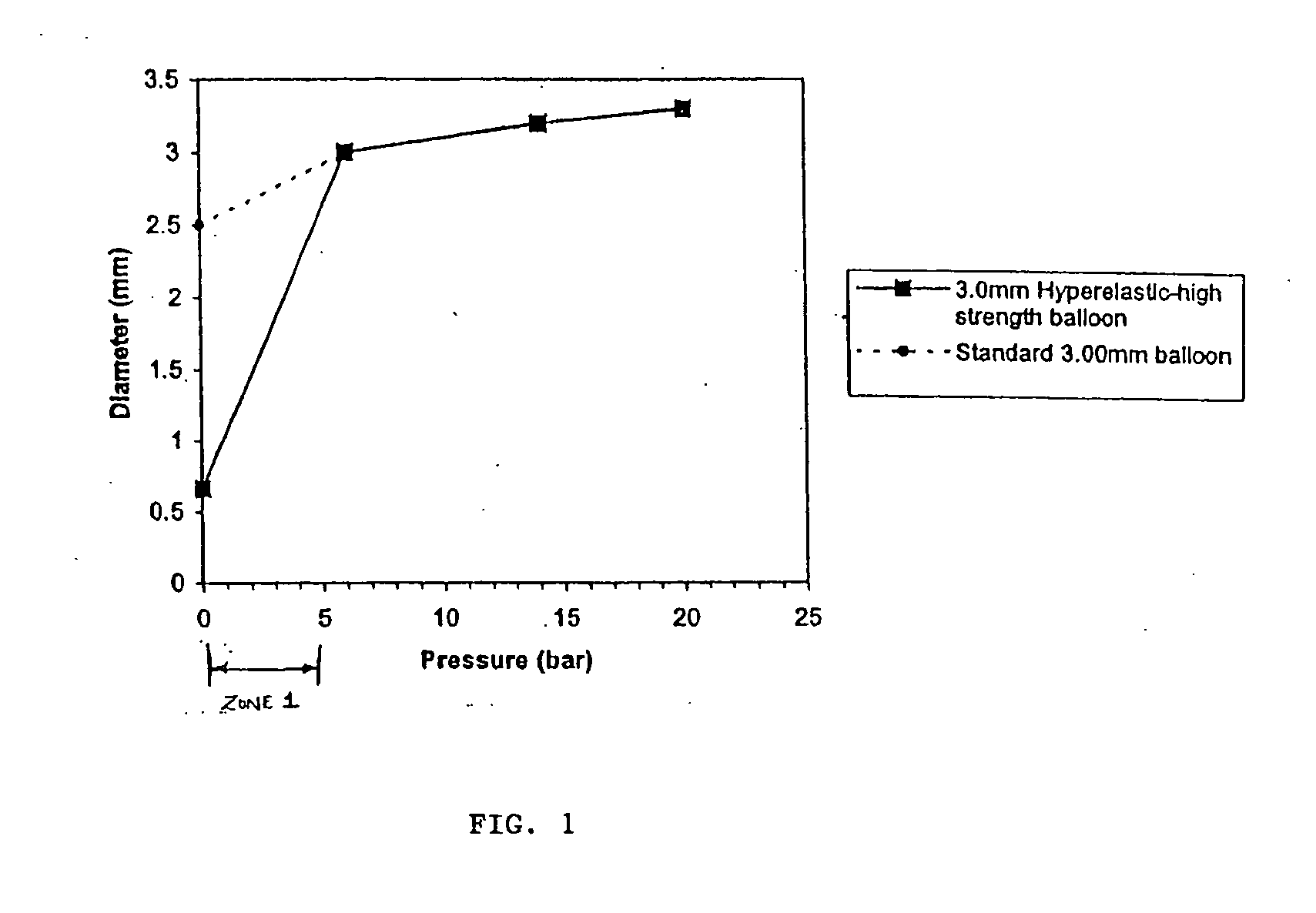

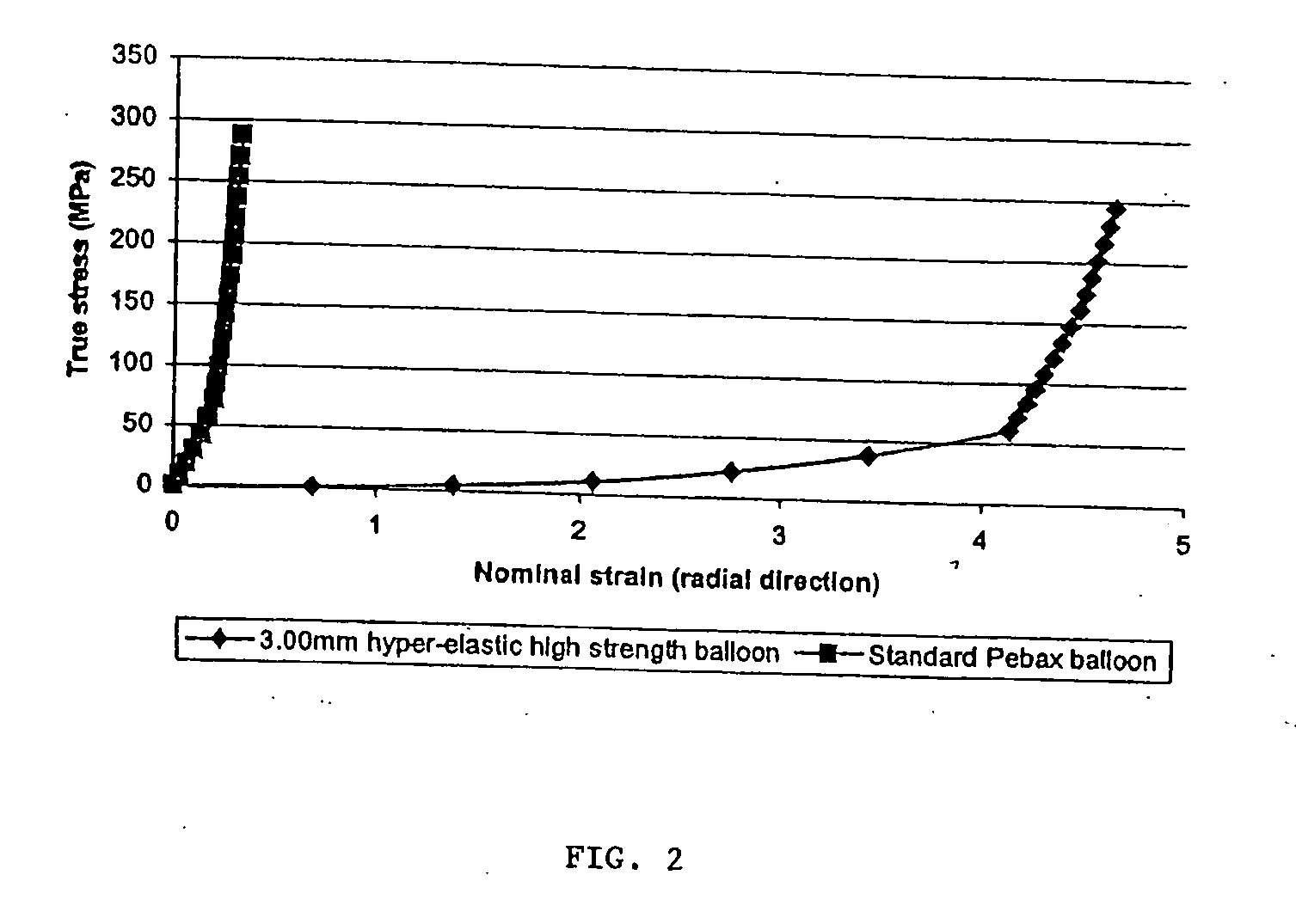

[0078] A polymeric extrudate was formed as a tubular preform for a dilatation balloon. A multiblock copolymer was used as the base material. A triblock copolymer was used having the structure (C-E-C), wherein C and E denote poly(cyclohexylethylene) (PCHE) and hydrogenated butadiene, respectively. The butadiene block is a mixture of 1-2 and 1-4 addition, which upon hydrogenation, results in a block of random poly(ethylene) (PE) and poly(ethylethylene) (PEE). The triblock copolymer is described in detail in U.S. Pat. No. 6,455,656 B2; U.S. Pat. No. 6,451,924 B1; U.S. Pat. No. 6,426,390 B1; and U.S. Pat. No. 6,376,621 B1, all of which are incorporated herein in their entireties by reference. The triblock polymer was dissolved in dioctylphthalate (DOP), where the polymer concentration was about 75 wt. %, thus creating a gel. The gel was extruded at a temperature just below the order-disorder transition temperature. The gel was subsequently drawn to 400%. The extruded and drawn samples w...

example 2

[0079] Following a similar procedure, a pentablock copolymer was extruded having structure (C-E-C-E-C), wherein C and E denote poly(cyclohexylethylene) (PCHE) and hydrogenated butadiene, respectively. The butadiene block is a mixture of 1-2 and 1-4 addition, which upon hydrogenation, results in a block of random poly(ethylene) (PE) and poly(ethylethylene) (PEE). The polymer is described in U.S. Pat. No. 6,455,656 B2; U.S. Pat. No. 6,451,924 B1; U.S. Pat. No. 6,426,390 B1; and U.S. Pat. No. 6,376,621 B1. For Deborah numbers between 0.1 and 100, the macroscopic microdomain alignment was perpendicular, and a transverse alignment was also seen for Deborah numbers between 10 and 100. Similar mechanical responses were measured for the pentablock copolymer as the triblock copolymer, except the pentablock copolymer was found to have superior strength-elasticity balance as compared with the triblock extrudate.

[0080] Following a similar procedure, one can produce tubular preforms comprising ...

example 3

[0082] Following a similar procedure as Example 1, a pentablock copolymer having molecular weight of about 65 kg / mole and comprising about 60 wt. % of the poly(cyclohexylethylene) block and about 10 wt. % of the poly(ethylethylene) block was mixed with dioctylphthalate to form a gel having about 75 wt. % polymer. The gel was extruded and the extrudate was pre-strained or aligned by hand. The elasticity and elastic recovery of the sample was studied using a tensile machine. FIGS. 6A and 6B show the stress vs. strain (hysteresis) curves. The curves show that the material is highly elastic and substantially recovers from strains of about 4, 10, 18 and 40% without permanent deformation. FIG. 6A shows no failure of the material until strains of about 120%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com