Industrial automation paint line

A coating production line and industrial automation technology, which is applied in the direction of surface coating liquid devices, coatings, and pre-treated surfaces, can solve problems such as unsatisfactory users and poor automation, and achieve powerful process information statistics and summary functions, Guaranteed data consistency and simple window interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present utility model.

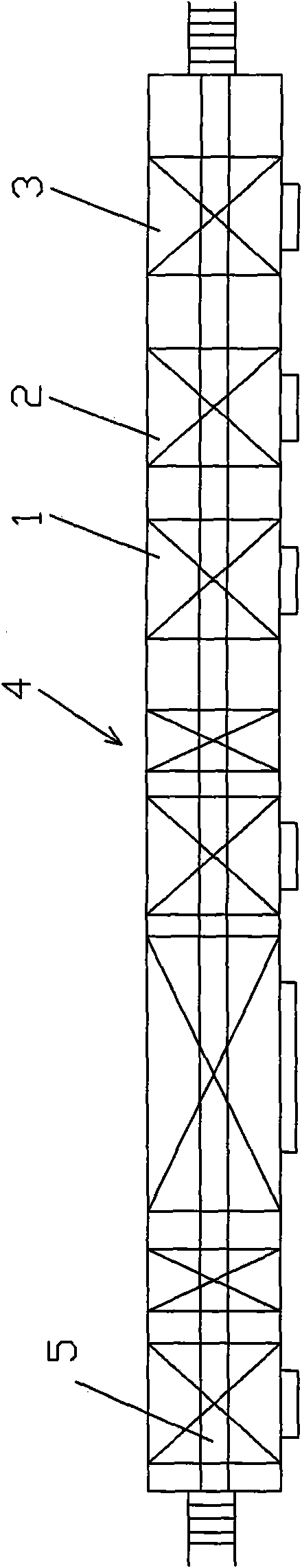

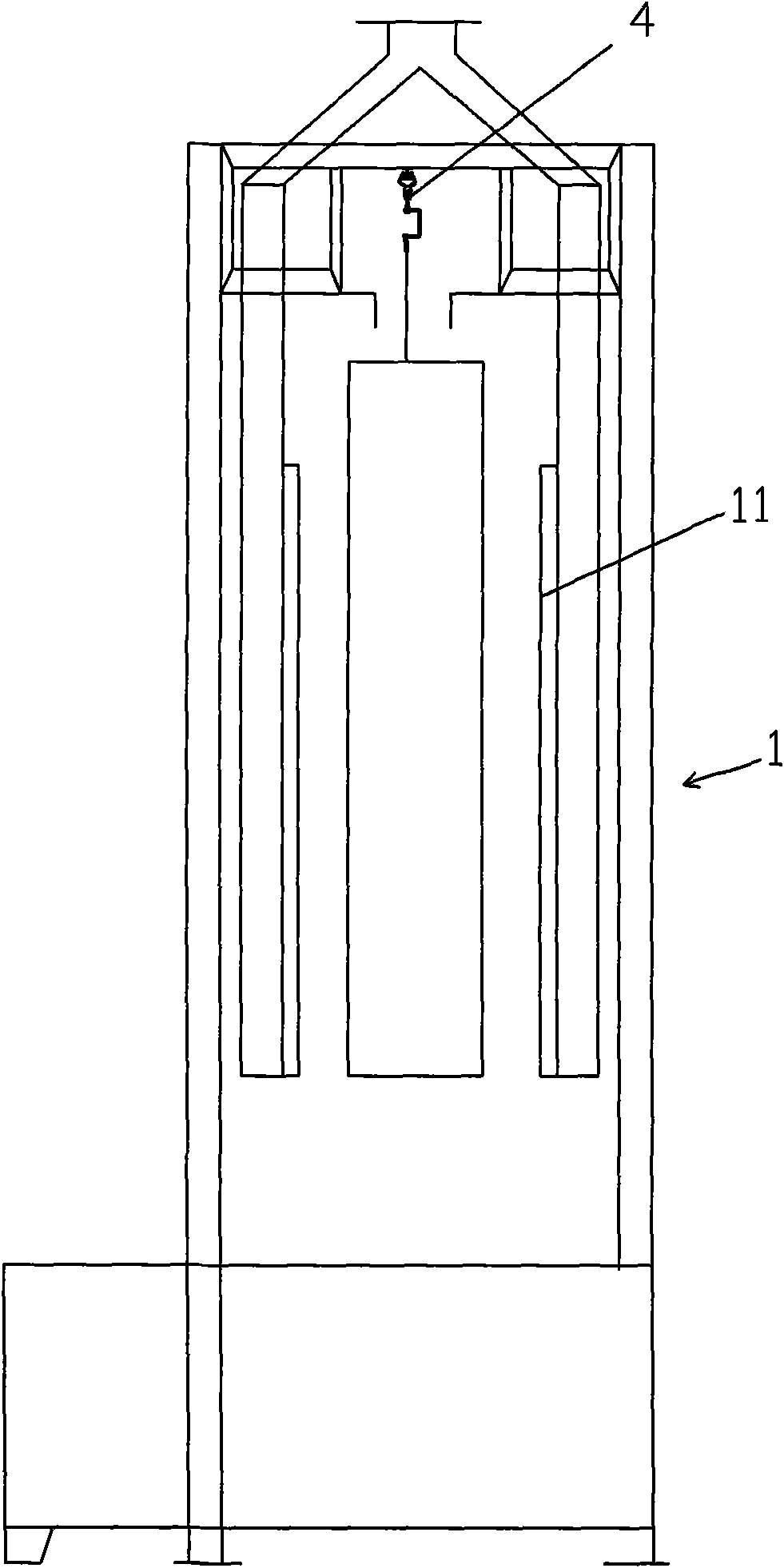

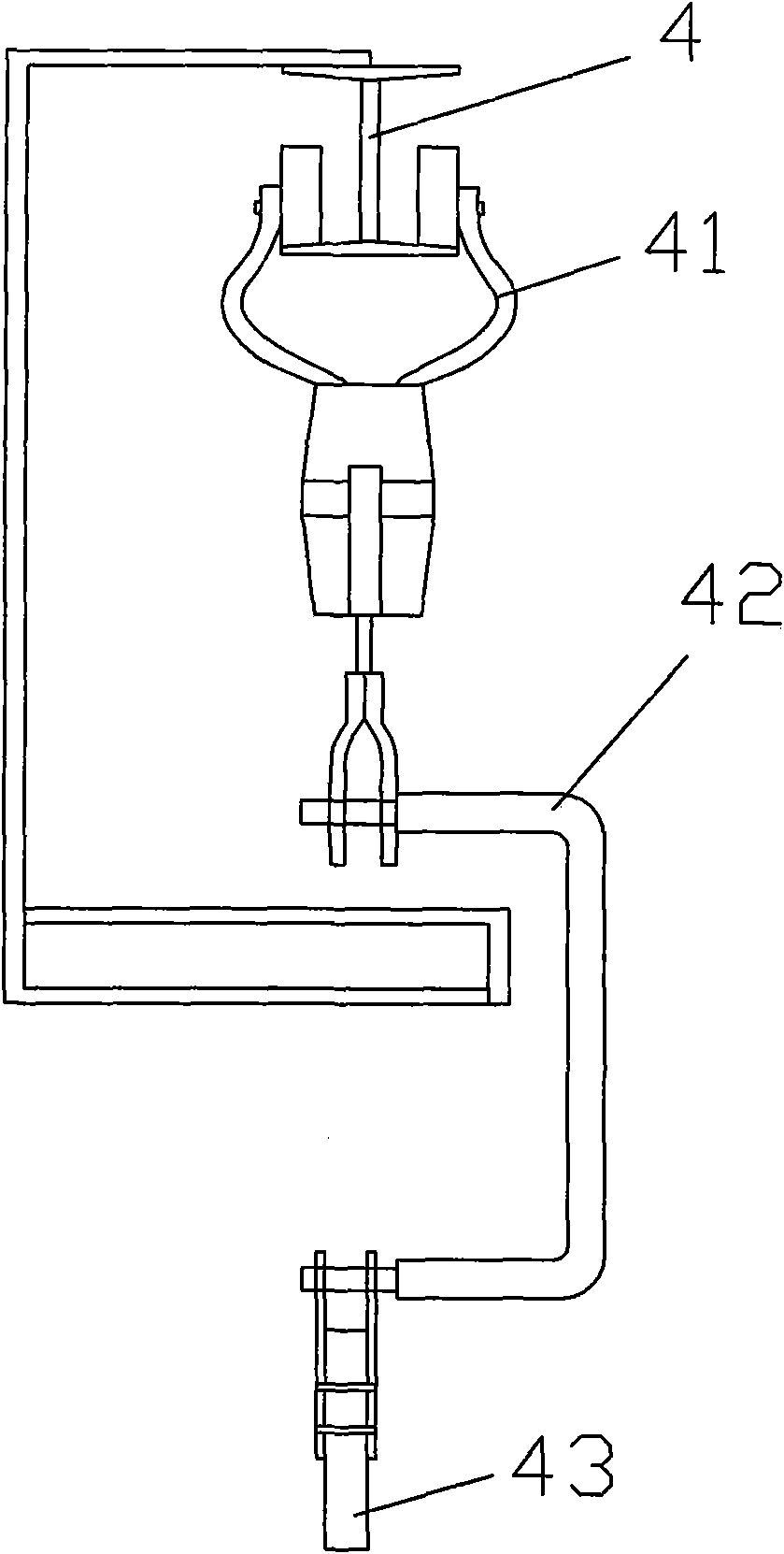

[0038] See figure 1 Shown in ~8: industrial automatic coating production line, including conveyor chain 4, ultrasonic pretreatment production line 5, drying chamber 1, spraying chamber 2 and curing chamber 3, the conveyor chain 4 is hinged with a suspension frame 41, the lower part of the suspension frame 41 A C-shaped hanger 42 is hinged, and the lower part of the C-shaped hanger is hinged with a suspension equalizing beam 43; the suspension equalizing beam 43 has a hanging workpiece hole 432 and a hinged hole 431;

[0039] On the top of the spray booth 2, a flow equalizing pipe 22 is fixed, and a flow equalizing filter layer 23 is fixed below the flow equalizing pipe 22. The below of the flow equalizing filter layer 23 is a painting workbench 21, and the flow equalizing filter layer 23 is a breathable fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com