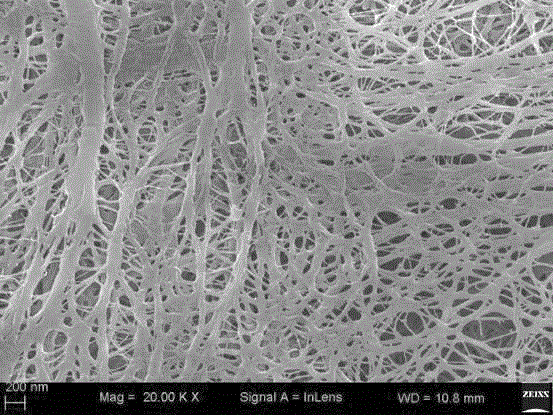

High-density polyethene micro porous membrane and preparation method therefor

A high-density polyethylene and microporous membrane technology, which is applied in the field of membrane materials, can solve the problems of complex membrane production process, large amount of solvents, environmental pollution, etc., and achieve the effect of simplifying the process, uniform pore distribution, and eliminating the extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

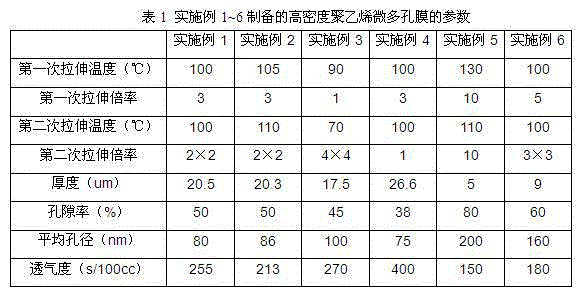

Embodiment 1

[0033] High-density polyethylene microporous film, prepared from the following raw materials by weight percentage: high-density polyethylene resin A30%, high-density polyethylene resin B15%, a mixture of isodecane and n-decane (mixing ratio 2:3) 54.9 %, antioxidant CA0.1%.

[0034] Among them, high-density polyethylene resin A is: density of 0.93 g / cm3, Mw of 4.5×10 5 (Mw / Mn=28), HDPE (polyethylene homopolymer) with a melt flow rate of 0.6 g / 10min and an average particle size of 3.3mm;

[0035] High-density polyethylene resin B is: density is 0.96 g / cm3, Mw is 2.5×10 5 (Mw / Mn=31), HDPE (polyethylene homopolymer) with a melt flow rate of 0.4 g / 10min and an average particle size of 3mm.

[0036] The steps of the preparation method are:

[0037] (1) Preparation of molten liquid: take high-density polyethylene resin A and high-density polyethylene resin B and mix to form a high-density polyethylene resin, and put the mixed high-density polyethylene resin into a twin-screw extruder (D=110m...

Embodiment 2

[0042] The high density polyethylene microporous membrane has the same raw material ratio and composition as in Example 1.

[0043] The preparation method refers to Example 1. The difference from Example 1 is that in step (3), the preheating temperature is 40°C, and the hot air temperature (ie, the stretching temperature) is 105°C during the first longitudinal stretching. The stretching ratio is 3 times, and the heat setting temperature is set to 110°C; in step (4), the hot air temperature (ie stretching temperature) is 110°C, and the second simultaneous bidirectional stretching ratio is MD×TD=2×2= 4 times, the heat setting temperature is set to 115°C.

Embodiment 3

[0045] The high density polyethylene microporous membrane has the same raw material ratio and composition as in Example 1.

[0046] The preparation method refers to Example 1. The difference from Example 1 is that in step (3), the preheating temperature is 60°C, and the hot air temperature (ie, the stretching temperature) is 90°C during the first longitudinal stretching. The stretching ratio is 1 times, and the heat setting temperature is set to 95°C; in step (4), the hot air temperature (that is, the stretching temperature) is 70°C, and the second two-way simultaneous stretching ratio is MD×TD=4×4= 16 times, the heat setting temperature is set to 75°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com