Thermal wind speed sensing device capable of performing zero compensation automatically and method for measuring wind speeds

A sensing device and zero-point compensation technology, which is applied in the direction of measuring fluid velocity by using thermal variables, can solve problems such as zero-point drift, anemometer sensitivity and accuracy problems, and hinder the improvement of thermal anemometer accuracy and sensitivity, so as to achieve accurate measurement , the effect of a wide range of wind speed measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

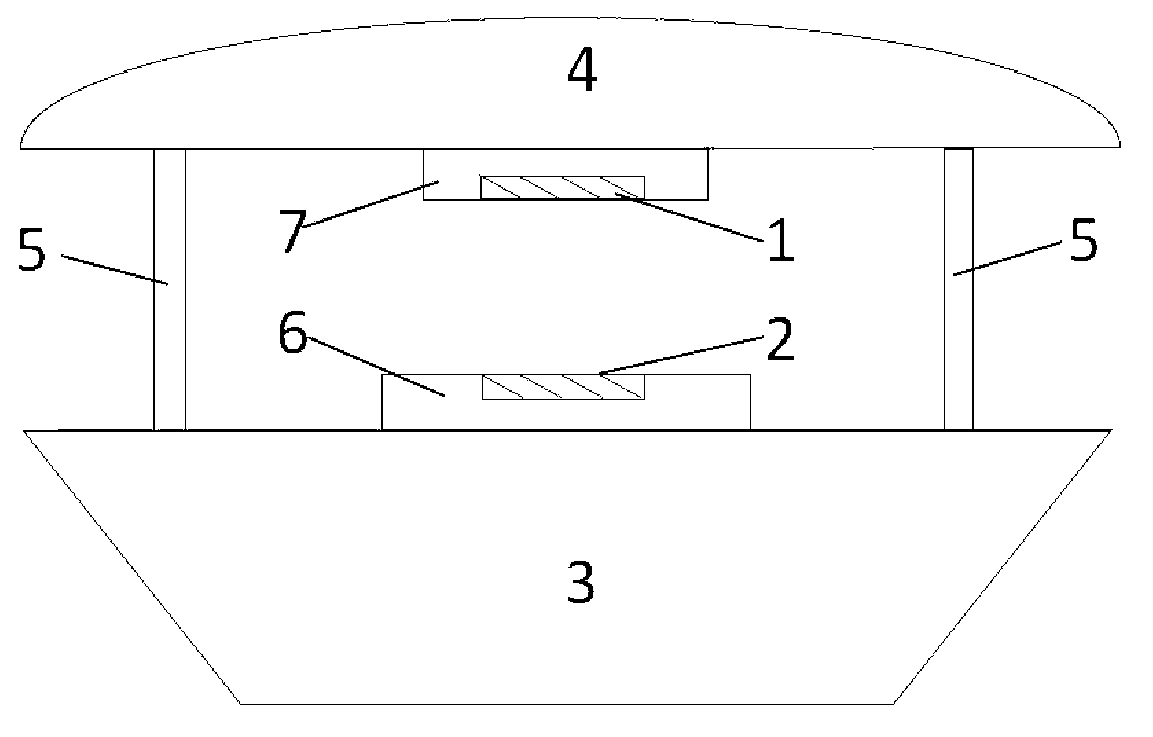

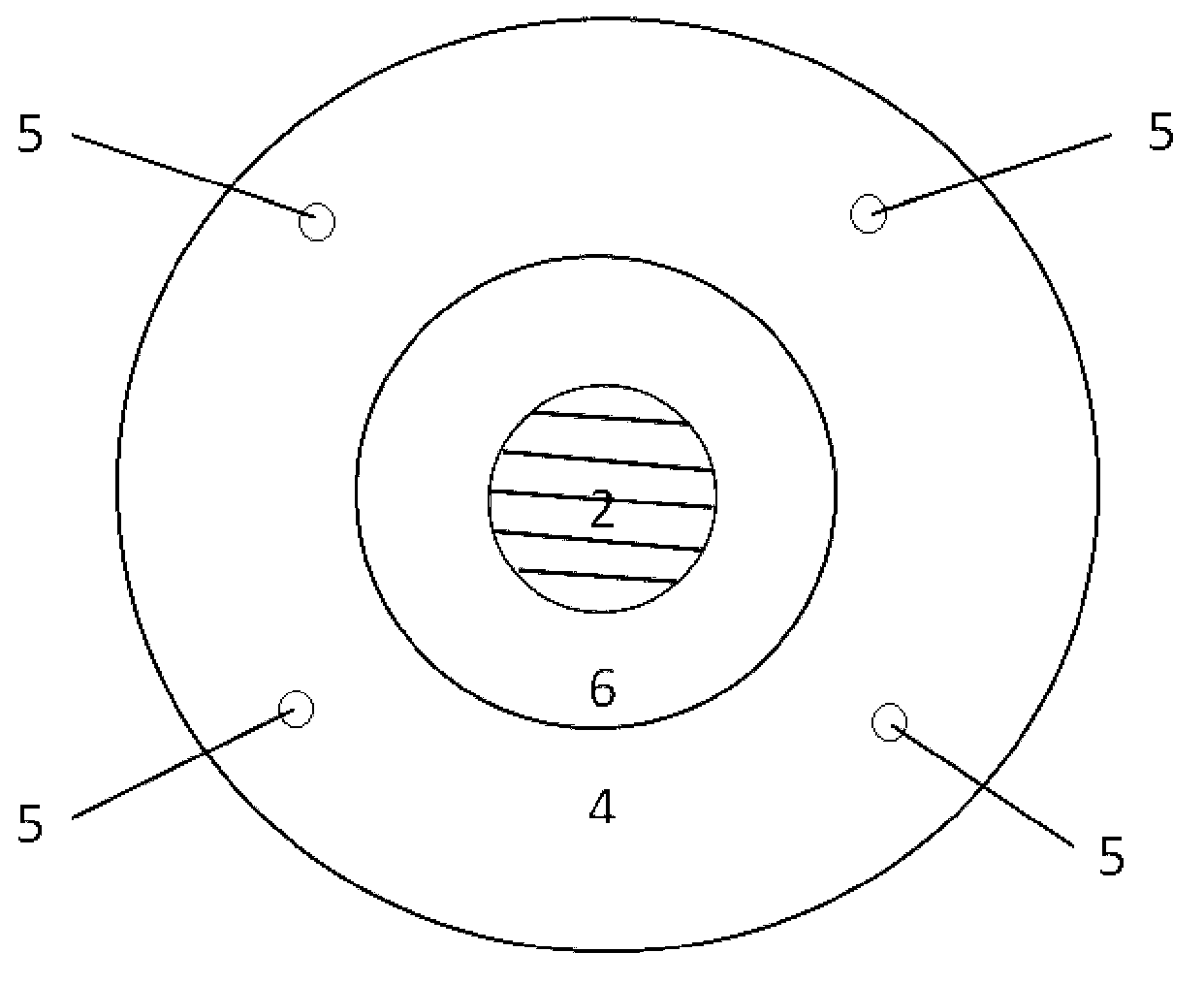

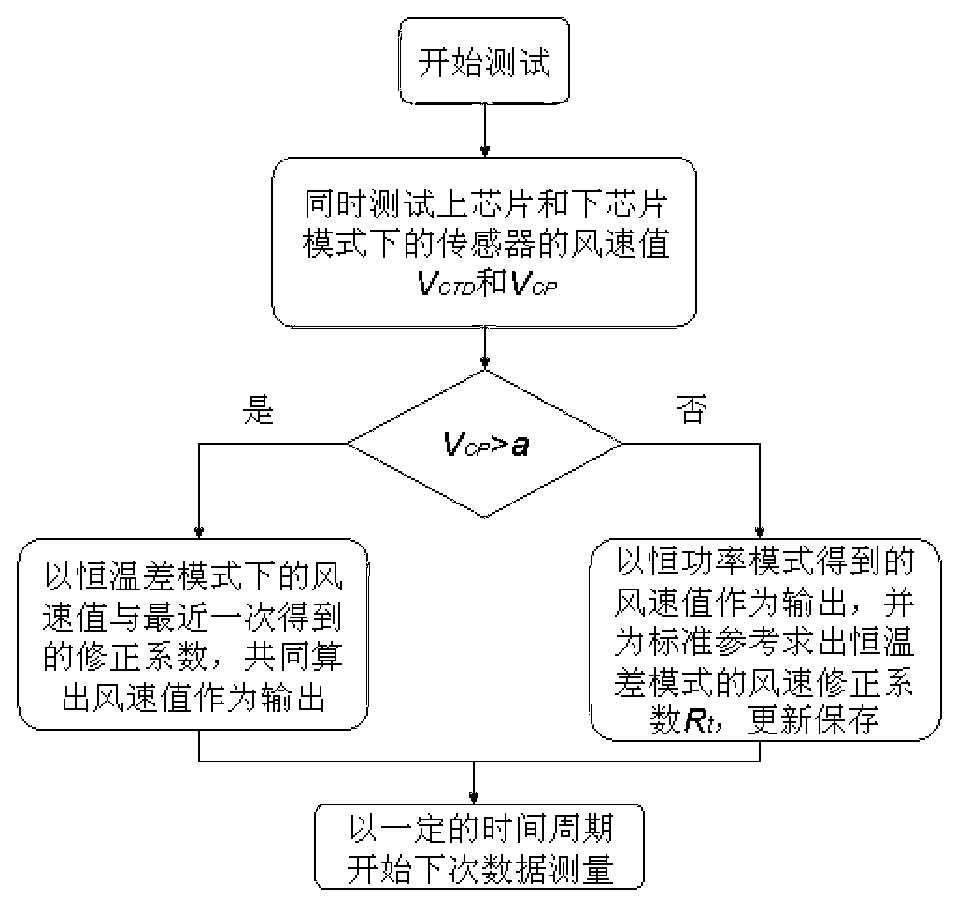

[0017] Such as figure 1 and figure 2 As shown, a thermal wind speed sensor device with automatic zero point compensation of the present invention includes

[0018] An upper sensor chip 1, a lower sensor chip 2, a top case 3, a bottom case 4, a support column 5, a lower support platform 6 and an upper support platform 7. The support columns 5 are connected between the top case 3 and the bottom case 4 , and gaps are formed between adjacent support columns 5 . The outside wind enters the thermal wind speed sensing device from the gap between the support columns 5 . The upper platform 7 is connected to the bottom of the top case 3 , and the upper sensor chip 1 is embedded in the bottom of the upper platform 7 . The lower support platform 6 is connected to the top surface of the bottom case 4 , and the lower sensor chip 2 is embedded on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com