Camellia oleifera fruit hulling treatment method through flotation separation

A processing method and technology of camellia husk, applied in wet separation, solid separation, chemical instruments and methods, etc., can solve problems such as poor processing efficiency, complete separation and prevention of damage, and reduce energy consumption for crushing and shelling. High efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

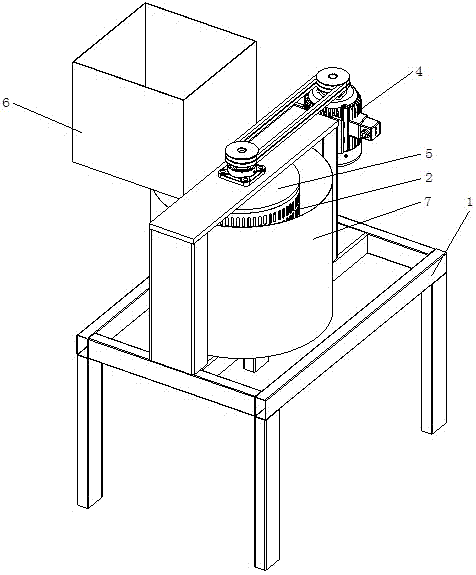

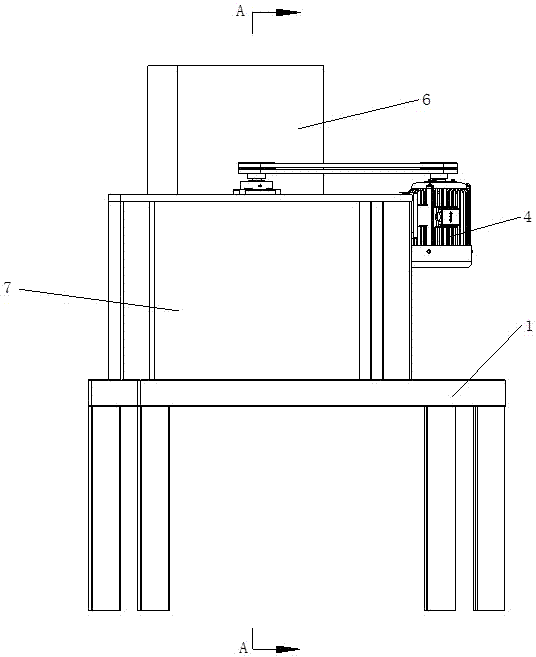

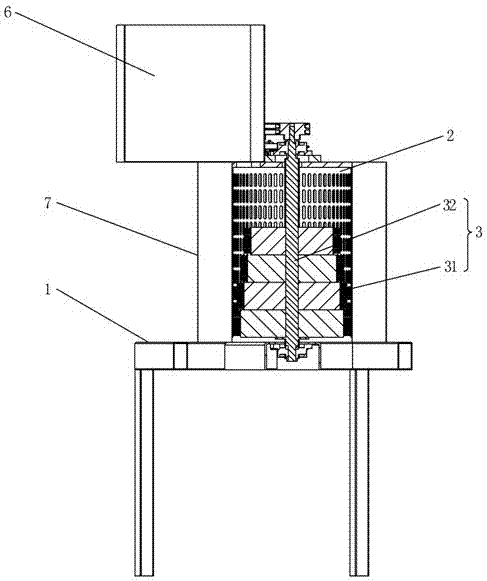

[0049] Embodiment 1 is the fruit throwing machine used in step (1).

[0050] Such as Figure 1 to Figure 3 As shown, the fruit throwing machine provided by the present invention includes a frame 1 and a shelling and crushing part, and the shelling and crushing part is installed on the frame 1, and the shelling and crushing part includes a screen drum 2, a roller 3 and a drive system 4, and the drive system 4 is used to drive the roller 3 to rotate, the screen cylinder 2 is fixed on the frame 1, the roller 3 is rotatably sleeved in the inner cavity of the screen cylinder 2, and the roller 3 is a cylindrical stepped structure with more than two levels on the outer circumference , a plurality of brush claws 31 for breaking the shell of camellia oleifera fruit are provided on the outer peripheral cylindrical step surface, and a gap with a large upper part and a smaller gap is formed between the ends of the plurality of brush claws 31 and the screen cylinder 2, that is, from top to...

Embodiment 2

[0060] A method for shelling camellia oleifera fruit by flotation separation, comprising the following process steps in sequence:

[0061] (1) Fruit throwing: freshly picked camellia oleifera fruit is put into the fruit throwing machine of embodiment 1, after the camellia oleifera fruit shell is polished clean, extrude and disperse to obtain a mixture of camellia oleifera seed and camellia oleifera shell, and the tea fruit picking time is ten Before and after the cold dew on the 30th day of the lunar month;

[0062] (2) Tempering: the mixture of camellia oleifera seed and camellia oleifera husk obtained in step (1) is air-dried and transported with hot air at 90°C for 30 minutes, and the moisture content of the husk is kept at 35%;

[0063] (3) Flotation: Carry out flotation with the mixture of camellia oleifera seed and camellia oleifera husk obtained in step (2), that is, to drop the mixture of camellia oleifera seed and camellia oleifera husk into a flotation liquid, which ...

Embodiment 3

[0070] The flotation liquid in step (3) of Example 3 is water, and the others are the same as in Example 2, the final seed breaking rate is 0.3%, the seeds contain 0.08% shells, and the shells contain 0.05% seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com