Round bin type cereal drying equipment

A grain drying, round silo-type technology, used in food drying, seed preservation by drying, food science, etc., can solve the problems of slow drying speed, broken, easy to appear burnt phenomenon, etc., to improve uniformity and speed up heating. Effect of Swap Speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the technical solution of the present invention will be described in detail through specific examples.

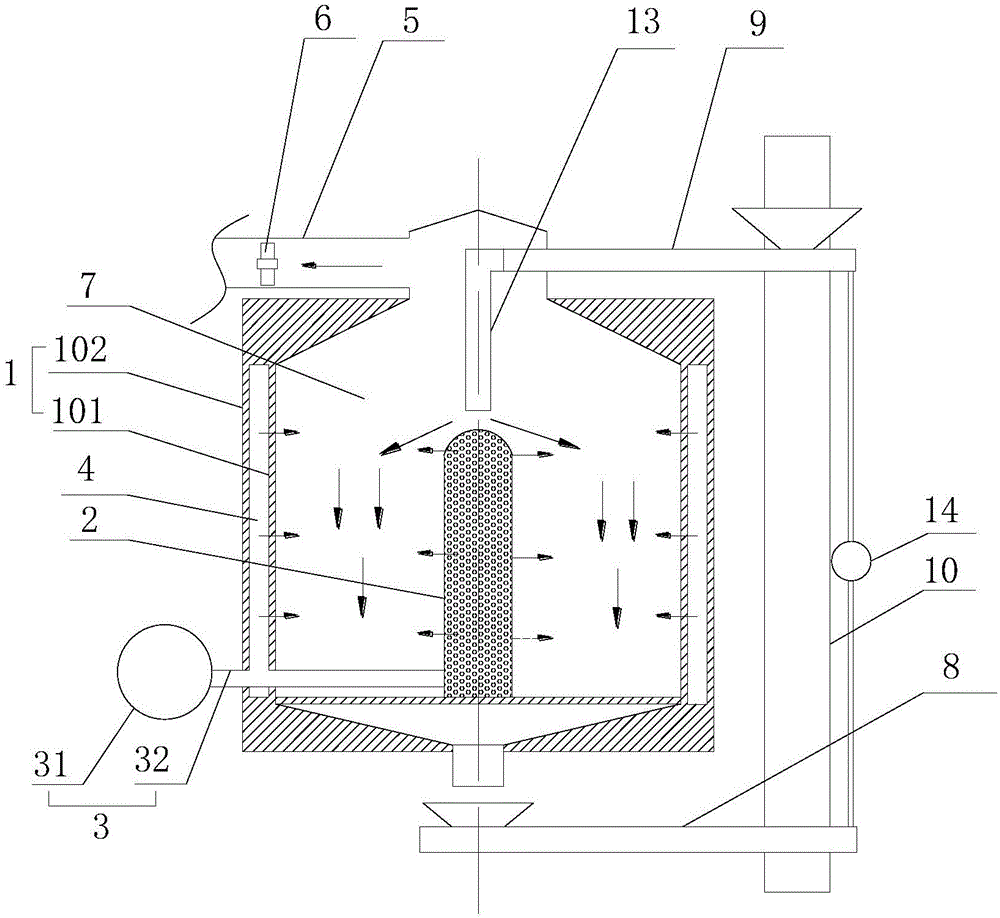

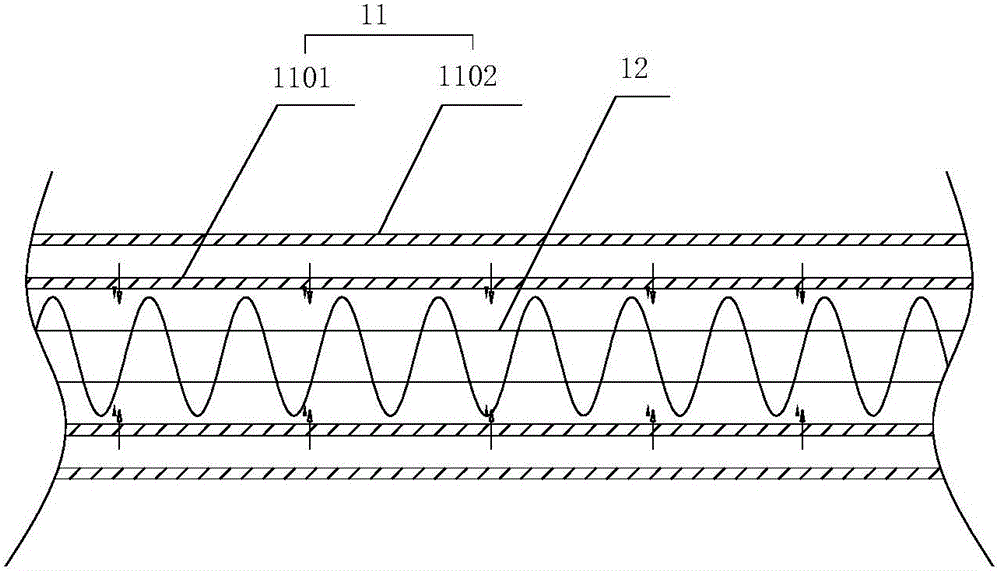

[0023] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a round bin type grain drying equipment proposed by the present invention; figure 2 It is a structural schematic diagram of the first screw conveying mechanism or the second screw conveying mechanism in a round silo grain drying equipment proposed by the present invention.

[0024] refer to Figure 1-2 , a round bin type grain drying equipment proposed in the embodiment of the present invention, comprising: a drying bin 1, an air supply cylinder 2, a hot air generating device 3, and a conveying device, wherein:

[0025] The drying bin 1 is provided with a feed port and a discharge port, and the discharge end of the drying bin 1 located at the feed port is connected with a feed pipe 13;

[0026] The drying bin 1 is a round bin, the side wall of the drying bin 1 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com