Fruit and vegetable drying machine

A drying machine, fruit and vegetable technology, applied in the fields of application, food processing, food science, etc., can solve the problems of affecting the drying effect of materials, insufficient drying of materials, high manufacturing cost, etc., to achieve enhanced drying effect and small footprint small size, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

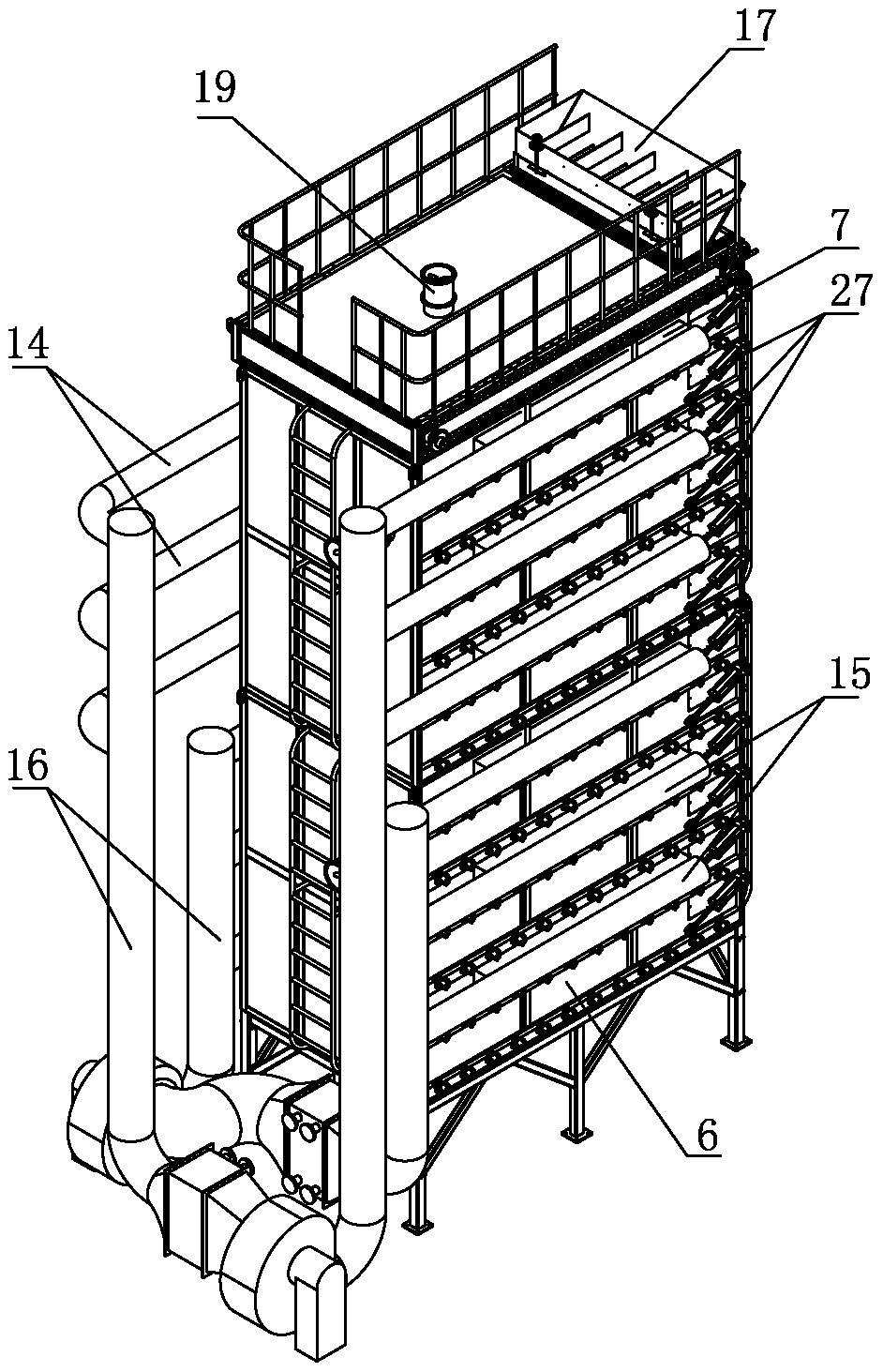

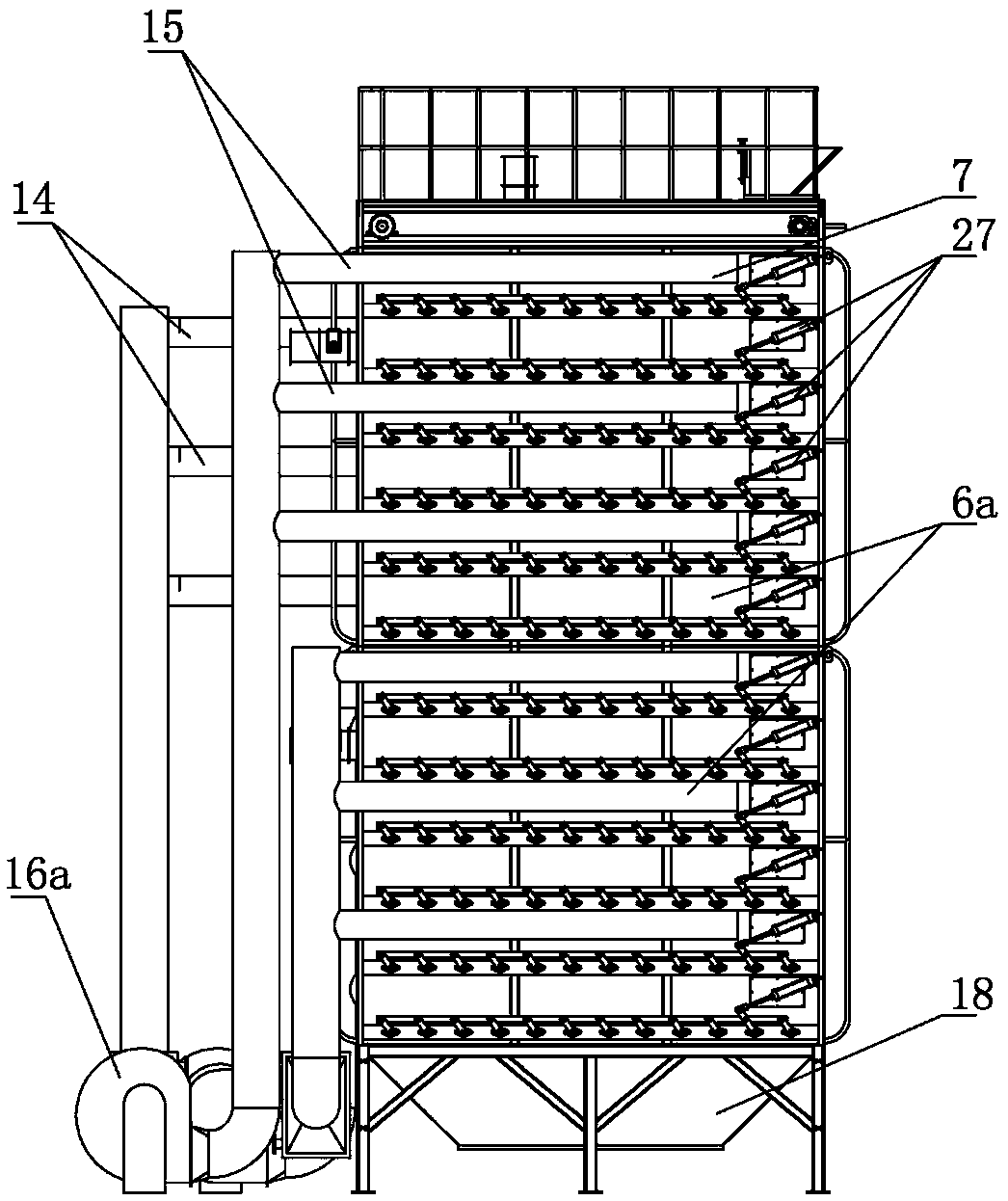

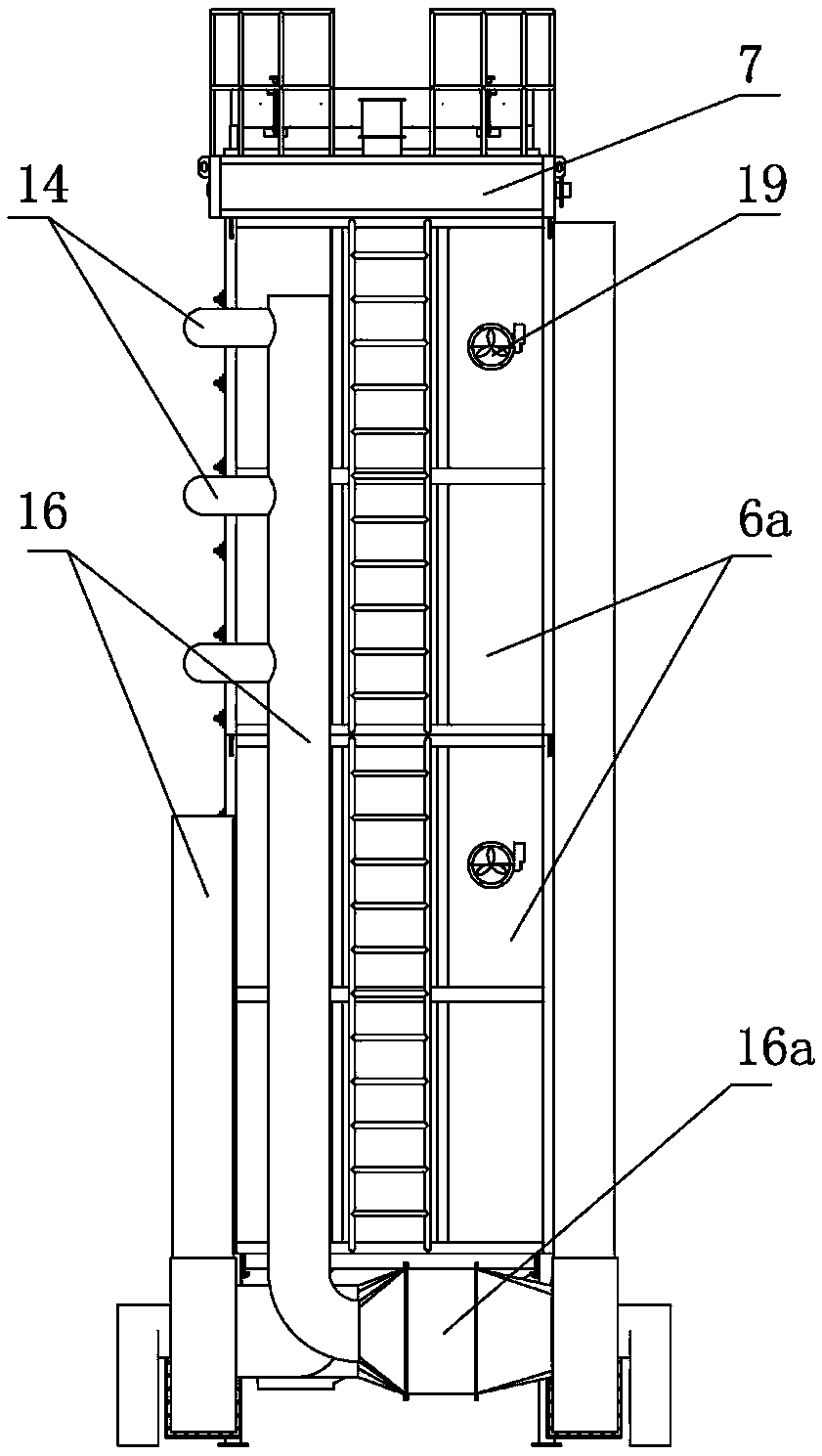

[0036] like Figure 1-18 As shown, it is a kind of fruit and vegetable dryer, which includes a drying chamber 6. The top of the drying chamber 6 is provided with a feeding port, and the upper part of the drying chamber 6 is provided with a distributing device 7 corresponding to the feeding port. The distributing device 7 can The material is evenly spread on several cloth flaps 2 arranged in sequence. The lower side of the cloth flap 2 is provided with a liftable support mechanism 9. The liftable support mechanism 9 is connected with the lifting drive device 10. The liftable support mechanism 9 There is a blanking channel for the material to fall, and the inside of the drying chamber 6 is arranged at least one layer of drying support layer 8 arranged vertically below the material distribution device 7. The drying support layer 8 includes a number of drying turns arranged in sequence. The plate 8a and the drying flap 8a are rotatably connected to the drying chamber 6 via the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com