Heat conducting adhesive tape and preparation method thereof

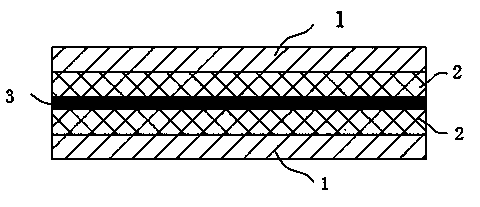

A technology of thermally conductive adhesives and tapes, applied in the direction of adhesives, non-polymer adhesive additives, film/sheet adhesives, etc. , to achieve the effect of easy large-scale mass production, convenient operation and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Pretreatment: Put 0.01mm thick aluminum foil in the pretreatment equipment for corona treatment for 40 minutes.

[0035] (2) Glue compounding: first dissolve 0.1 part of titanate coupling agent in 10 parts of toluene, add it to 100 parts of acrylic pressure-sensitive adhesive (solid content: 50% by weight, viscosity: 10000 cps), and stir for 5 minutes. Then, divide 200 parts of alumina (70% with a particle size of 5-15 μm and 30% with a particle size of 0.5-1 μm) into 3 parts, and add it to the acrylic pressure-sensitive In the glue solution, add once every 20 minutes. After all the thermal conductive fillers are added, stir for 10 minutes and add 1.5 parts of isocyanate, and then stir for 80 minutes;

[0036] (3) Coating: Put the corona-treated aluminum foil on the coating machine, apply glue on one side, and pass the temperature at a speed of 15m / min at 60°C, 70°C, 80°C, 90°C, 80°C, Dry in a six-section oven at 70°C to obtain a thermally conductive adhesive layer...

Embodiment 2

[0038] (1) Pretreatment: Put 0.05mm thick silver foil in the pretreatment equipment for ion source treatment, and the treatment time is 20min.

[0039] (2) Glue compounding: first dissolve 1.5 parts of titanate coupling agent in 4 parts of xylene, add them together to 100 parts of acrylic pressure-sensitive adhesive (solid content is 55% by weight, viscosity is 5000cps), and stir for 20 minutes . Then, divide 100 parts of aluminum nitride into 3 parts (70% of the particle size is 5-15μm, 30% of the particle size is 0.5-1μm), and add it to the acrylic press under the condition of constant stirring. In the sensitive glue solution, add once every 15 minutes. After all the thermal conductive fillers are added, stir for 5 minutes and add 0.1 part of tetraisopropoxytitanium, and then stir for 60 minutes;

[0040] (3) Coating: Put the silver foil treated by the ion source on the coating machine, apply glue on one side, and pass the temperature at 20m / min at a speed of 60°C, 70°C, 80...

Embodiment 3

[0042] (1) Pretreatment: Place the 0.03mm thick copper foil in the pretreatment equipment for plasma treatment, and the treatment time is 50min.

[0043] (2) Glue compounding: first dissolve 0.9 parts of titanate coupling agent in 5 parts of ethyl acetate, and add them to 100 parts of acrylic pressure-sensitive adhesive (solid content: 60% by weight, viscosity: 14000cps), stir 10min. Then divide 100 parts of alumina (particle size 5-15 μm, 70% by weight) and silicon carbide (particle size 0.5-1 μm, 30% by weight) into 3 parts, and keep stirring In the case of the acrylic pressure-sensitive adhesive solution, add it every 15 minutes. After all the thermal conductive fillers are added, stir for 15 minutes and add 0.8 parts of isocyanate and titanium tetraisopropoxide, and then stir for 100 minutes;

[0044] (3) Coating: Put the plasma-treated copper foil on the coating machine, apply glue on one side, and pass the temperature at a speed of 18m / min at 70°C, 80°C, 90°C, 100°C, 90°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com