IGBT device capable of improving switch-on and switch-off speed and switch-on and switch-off uniformity and manufacturing method thereof

A technology of switching speed and uniformity, applied in the field of power devices and their manufacturing, can solve the problems of poor switching uniformity, slow switching speed of IGBT devices, and speed up the transmission speed of gate voltage, so as to reduce switching loss, realize simple structure, and improve Effects of switching speed and switching uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

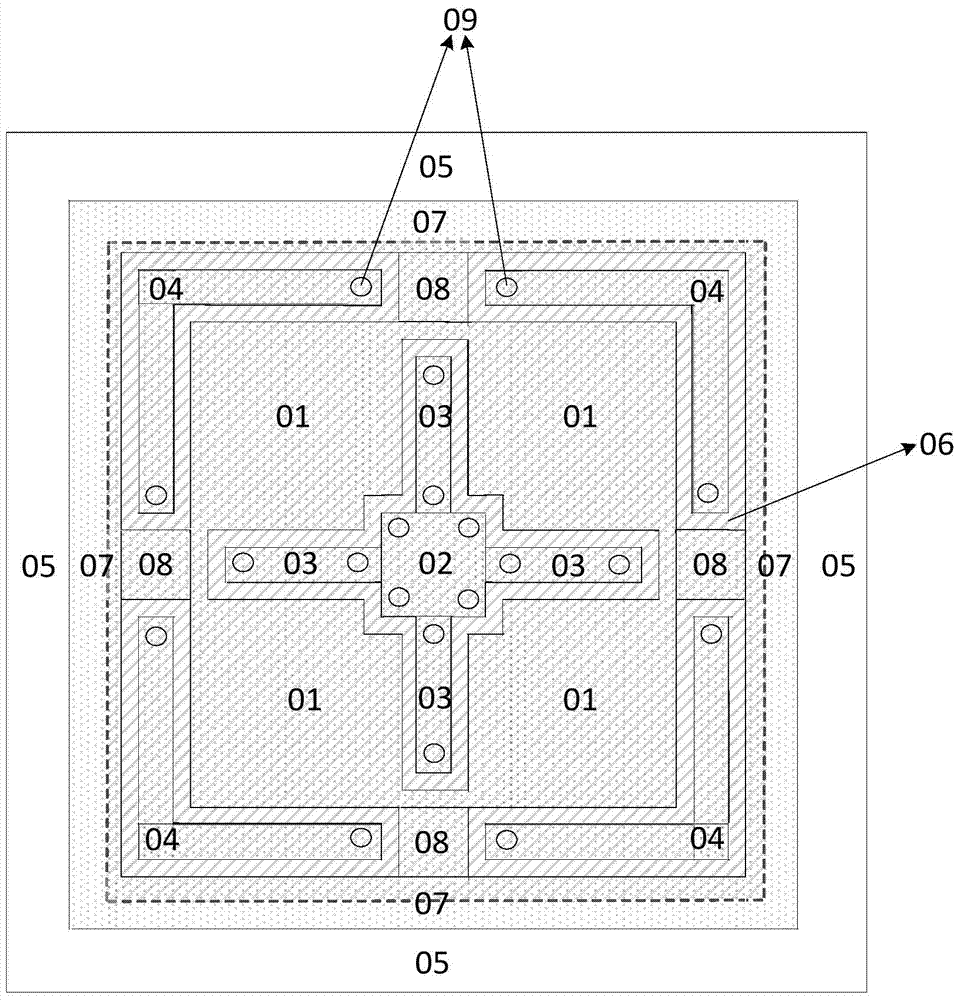

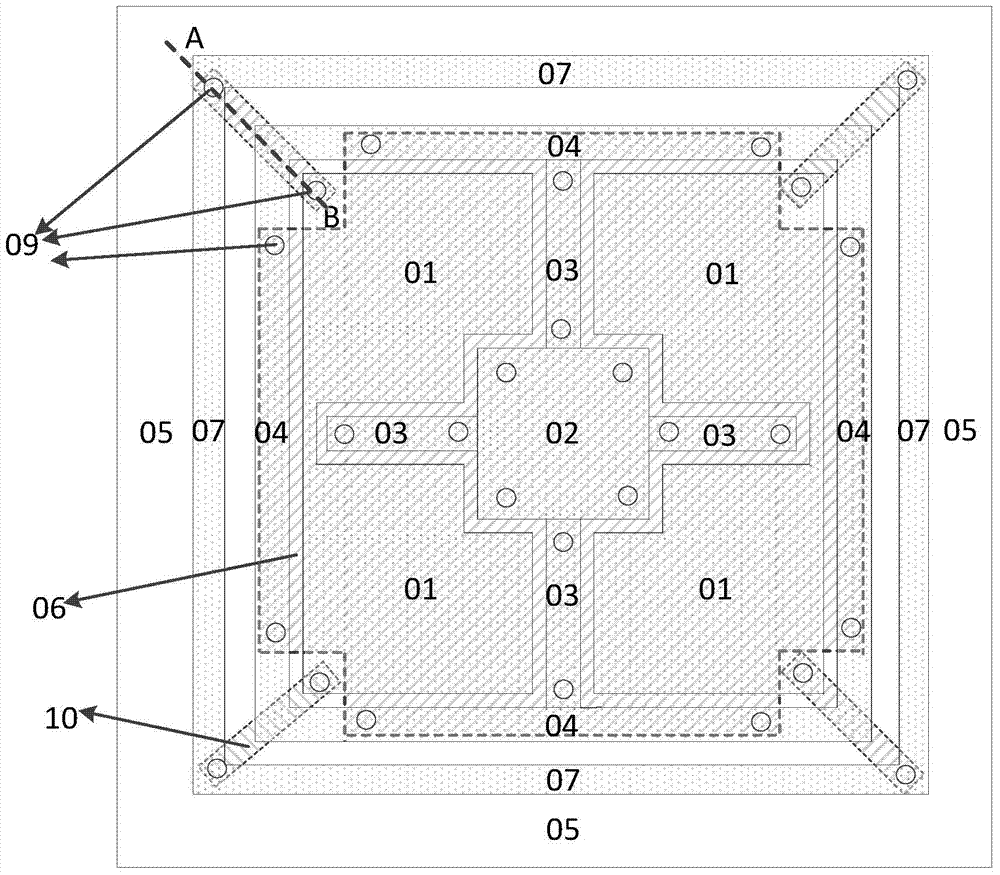

[0052] Embodiment 1 (with figure 2 Take the generation process of the cross-sectional diagram of the dotted line AB as an example)

[0053] The present invention also provides a method for manufacturing an IGBT device with enhanced switching speed and switching uniformity, comprising the following steps:

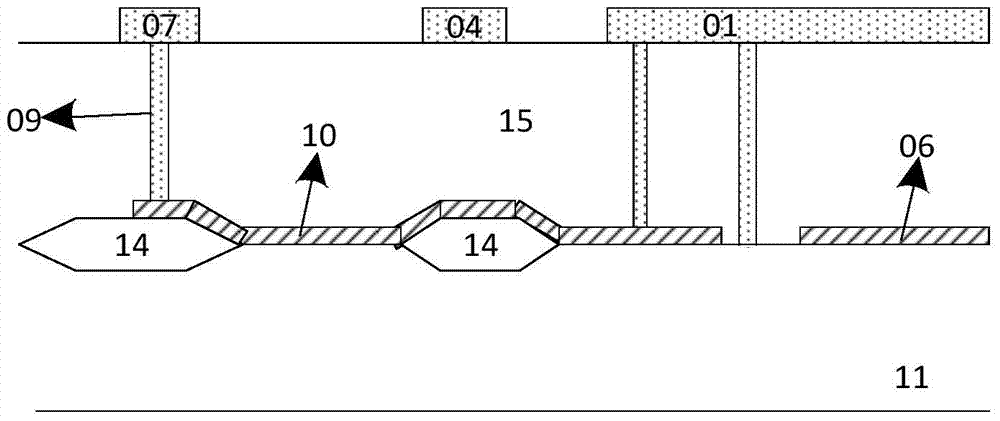

[0054] (1) A thin oxide layer is grown on the uniformly doped N-type substrate 11 as a barrier layer, and after processes such as coating, exposure, development, and deglue, the field-limiting ring P-Ring12 doped in the terminal area is engraved The window is P-Ring doped by ion implantation. After the same process, the N-Ring13 doping of the field limiting ring in the terminal area is carried out, such as Figure 4 shown.

[0055] (2) Field oxide layer 14: use high temperature oxidation method to grow a thick oxide layer on the surface of the silicon wafer, use the field oxide layer photolithography plate, go through glue coating, exposure, development, oxide film etchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com