Heating bottom plate of 3D printer

A technology for 3D printers and heating plates, which is applied to the processing of heating elements, processing platforms/substrates, and additive processing. To replace the high-temperature double-sided tape, improve the quality, and reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

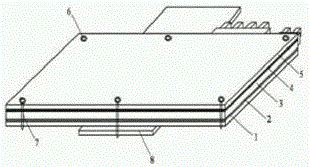

[0013] Such as figure 1 , the present invention provides a multifunctional heating plate for the bottom of a 3D printer, which includes a metal supporting plate 1, a thermal insulation plate 2, a metal ceramic heating plate 3, a high temperature resistant heat conducting film 4, a high temperature glass plate 5, and the metal supporting plate 1 is preferably an aluminum alloy pallet, and the metal pallet 1 is provided with six small round holes 6, and an insulation board 2 is placed directly above it; the insulation board 2 is preferably a ceramic fiber board, and the insulation board 2 is provided with six small round holes 6. Round hole 6, a metal-ceramic heating plate 3 is placed directly above it; six small round holes 6 are arranged on the metal-ceramic heating plate 3, and a high-temperature-resistant heat-conducting film 4 is placed directly above it; the high-temperature-resistant heat-conducting film 4 There are six small round holes 6, and a high-temperature glass pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com