Structure of low temperature solid oxide fuel cell supported by porous metal

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, fuel cell components, fuel cells, etc., can solve problems affecting battery life, deposition, and electrochemical reaction performance of batteries, and achieve improved electrocatalysis Performance, high efficiency, stress-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following

[0016] Example.

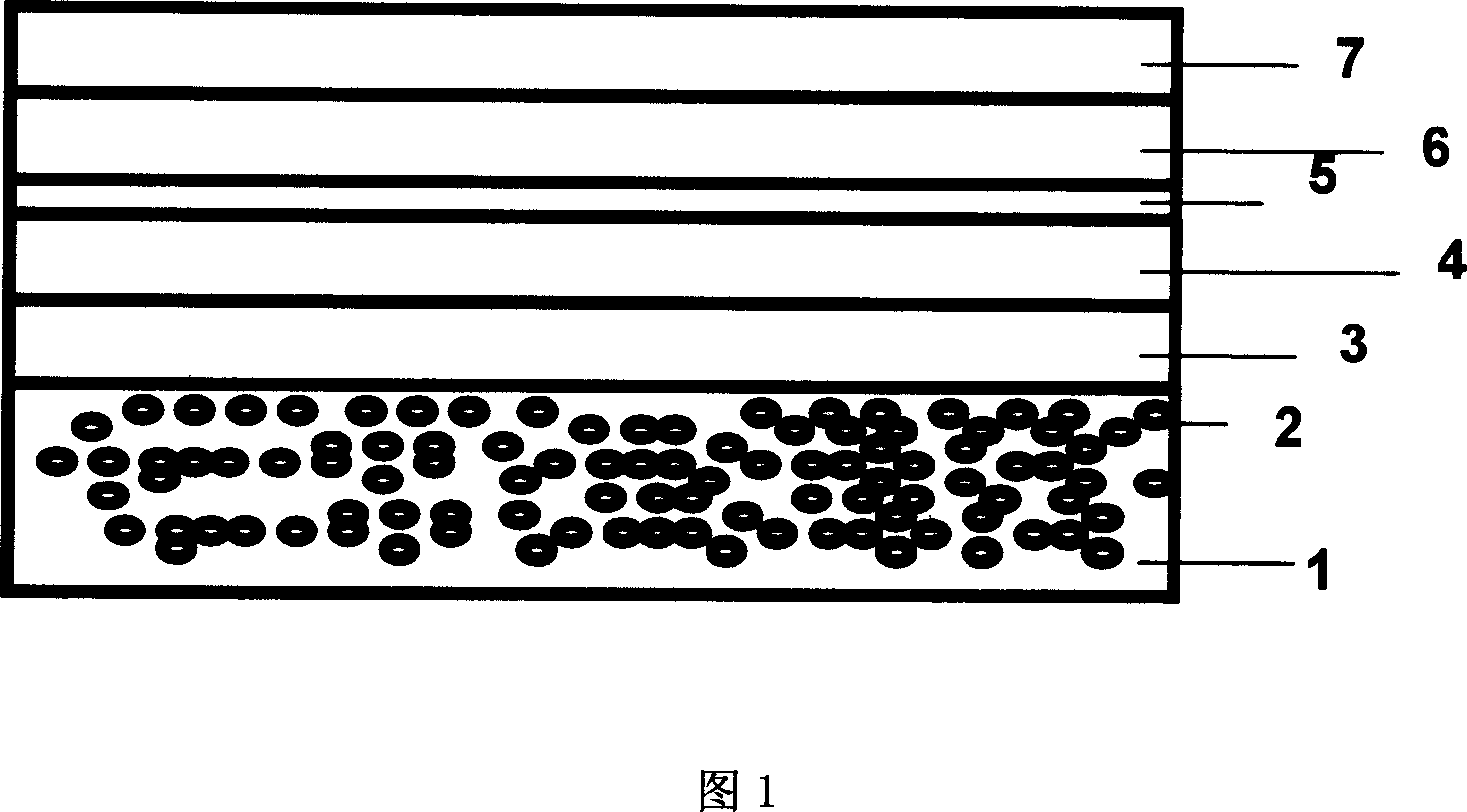

[0017] As shown in FIG. 1 , this embodiment includes: a porous stainless steel support 1 , a reforming catalyst 2 , a porous anode film 3 , a dense solid electrolyte film 4 , a reaction barrier layer 5 , a cathode activation layer 6 , and a cathode contact layer 7 .

[0018] The connection relationship of each component is as follows: in the porous stainless steel support body 1, the reforming catalyst 2 is impregnated, which is used to catalyze the reformation of different types of fuels into hydrogen-rich anode gas, on the porous stainless steel support body 1, by spraying Or the screen printing method deposits t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com