Pure inorganic perovskite light emitting diode device manufacturing method

A technology of light-emitting diodes and inorganic calcium, which is applied in the fields of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of complex process, small selection of hole transport materials, long preparation time, etc., and achieves the difficulty of preparation. Low, improve the flatness and uniformity, the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The formation process of the perovskite layer:

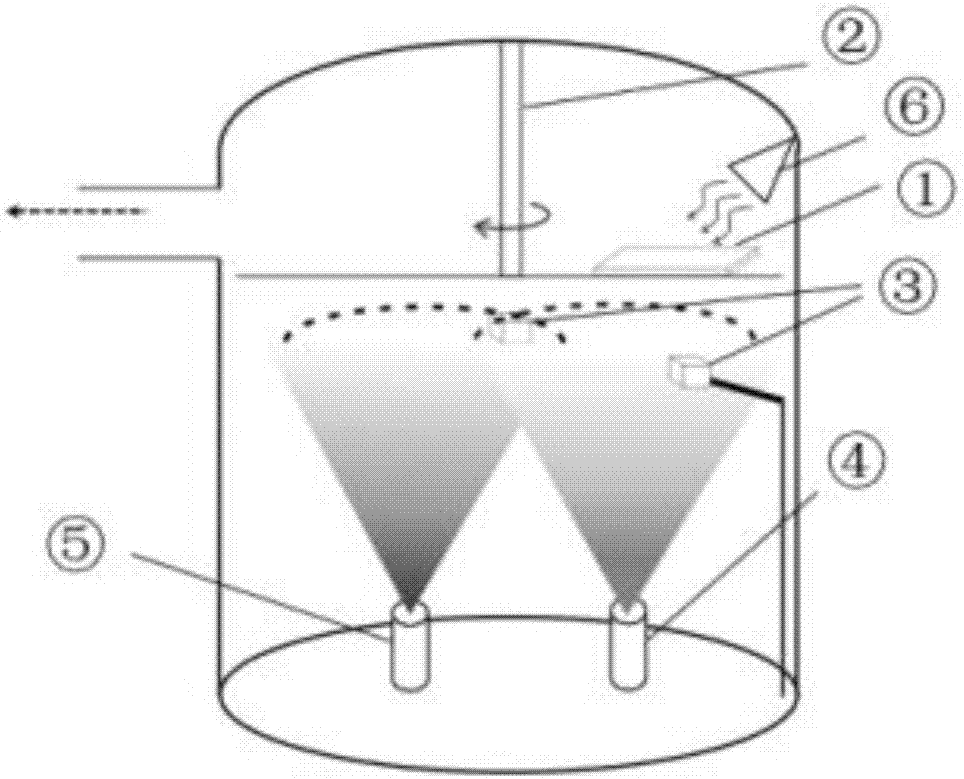

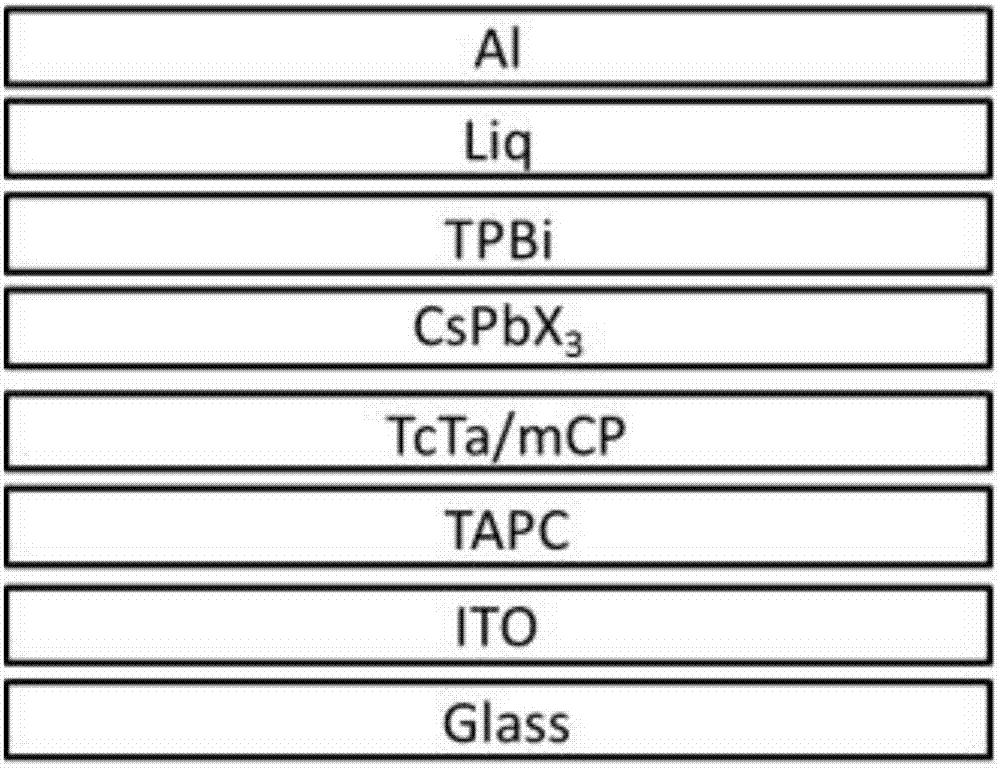

[0031] The perovskite material is placed directly in a grooved handmade tantalum skin boat and heated. The organic small molecule material is placed in the quartz boat, and the quartz boat is placed on the handmade tantalum skin. Precursor material CsPbX 3 It can be heated and sublimated to generate a beam, and the tray for placing ITO ( figure 1 Middle ②) Deposit perovskite molecular layers layer by layer at a speed of 25 rpm to form perovskite crystals. The grain size of perovskite can be controlled by rotation speed and evaporation rate. Here, the rotation speed and evaporation rate were optimized to 25 rpm and 1 Å / s. During the deposition process, the host and guest perovskite materials PbBr 2 , the position of CsBr is controlled to be 180° to achieve the uniform deposition of monoatomic layers to form lattice-dense perovskite layers. When the molar ratio of Pb and Cs precursor materials is 1:1.2, the produced P...

Embodiment 2

[0041] Example 2

[0042] The difference with Example 1 is that the method of dual-source co-evaporation is adopted in step 4, with PbI 2 CsI is the host material, CsI is the guest material, and the molar ratio is 1 to 1.2, forming a perovskite light-emitting layer.

Embodiment 3

[0044] The difference between embodiment 3 and embodiment 1 is that in step 4, the method of dual-source co-evaporation is adopted, and PbCl 2 As the host material, CsCl as the guest material, the molar ratio is 1 to 1.2, forming a perovskite light-emitting layer.

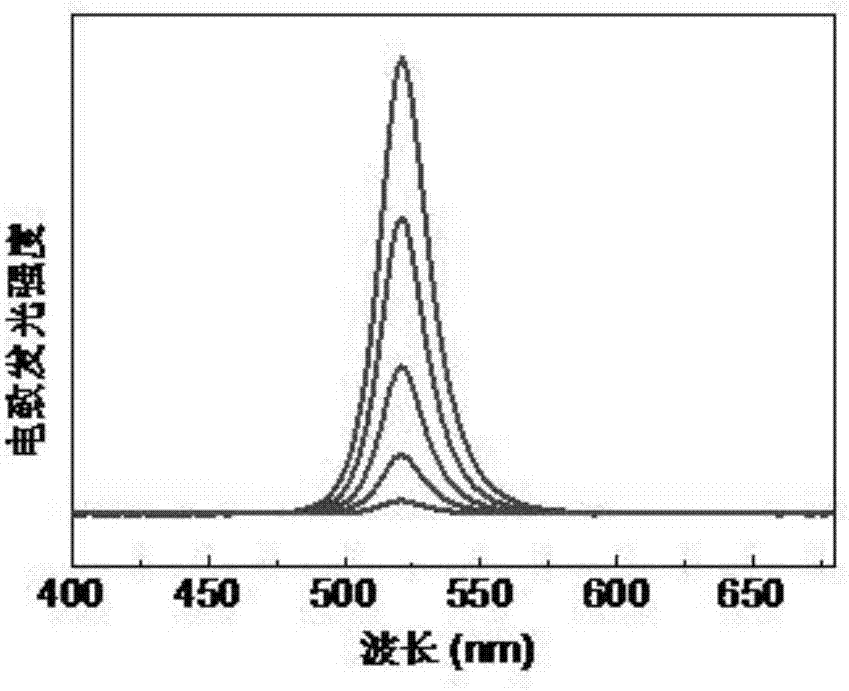

[0045] With the ITO substrate after the 5th step processing in embodiment 1, use the fluorescent spectrogram that the fluorescent spectrometer tests to obtain, from image 3 It can be seen from the figure that the fluorescence peak of the inorganic perovskite layer in Example 1 is at the position of 524 nm, and the half-wave width is 19 nm; Figure 4 It can be seen that the peak positions of the inorganic perovskite layer in Example 1 are at (100), (110), (200), and (202). Place the ITO substrate processed in the fifth step in Example 1 in the vacuum chamber of a photoelectron spectrometer (XPS), and evacuate to 2.0×10 -8 Pa, UV photoelectron spectrum measured with HeI as UV light source (21.2 eV), from Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com