Large phase ratio liquid-liquid two-phase continuous extraction apparatus

An extraction device and liquid membrane technology, applied in the field of liquid-liquid solvent extraction and separation, can solve problems such as difficult operation, inability to distinguish light and heavy phases with self-priming agitators, and reduced processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

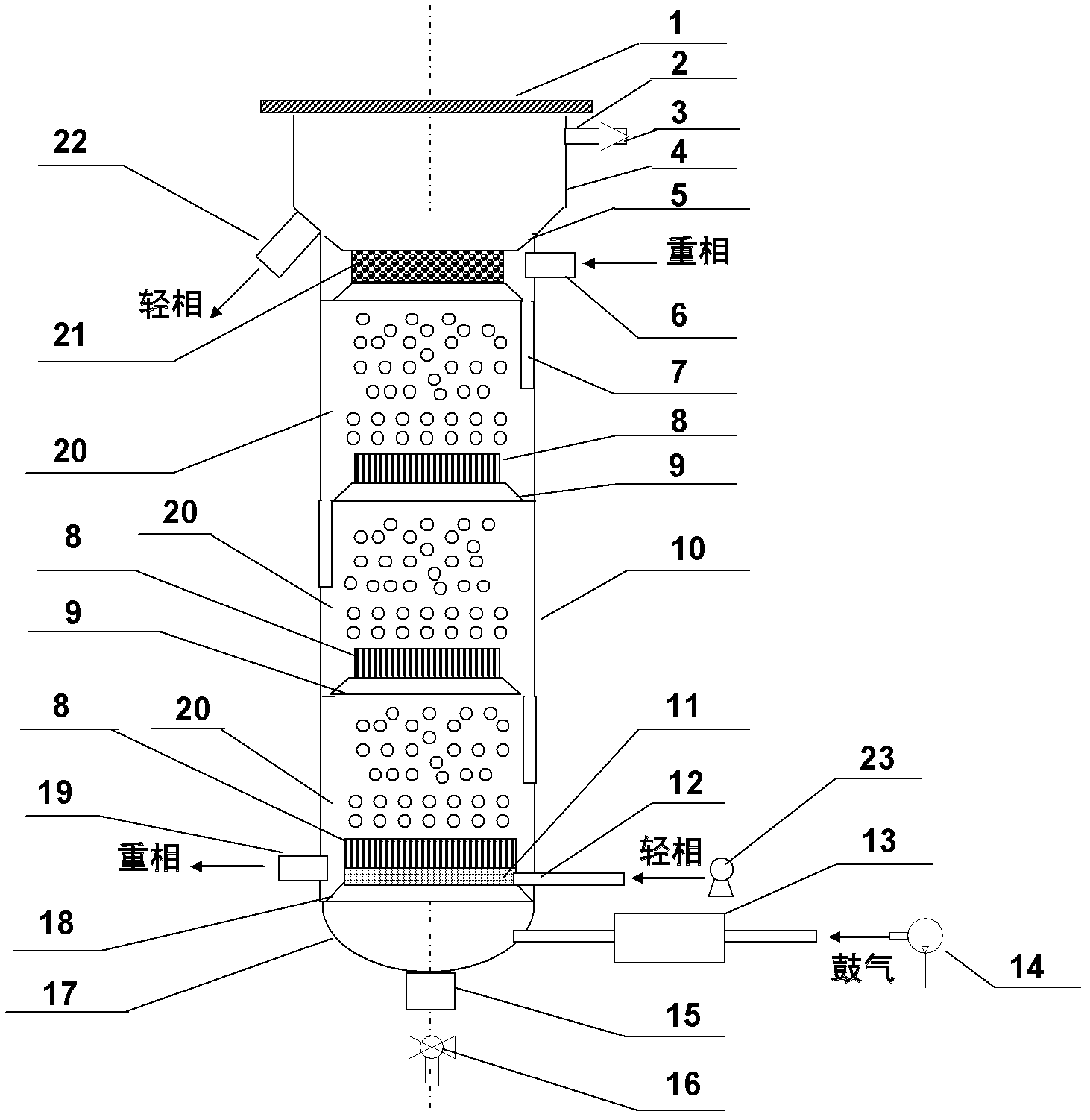

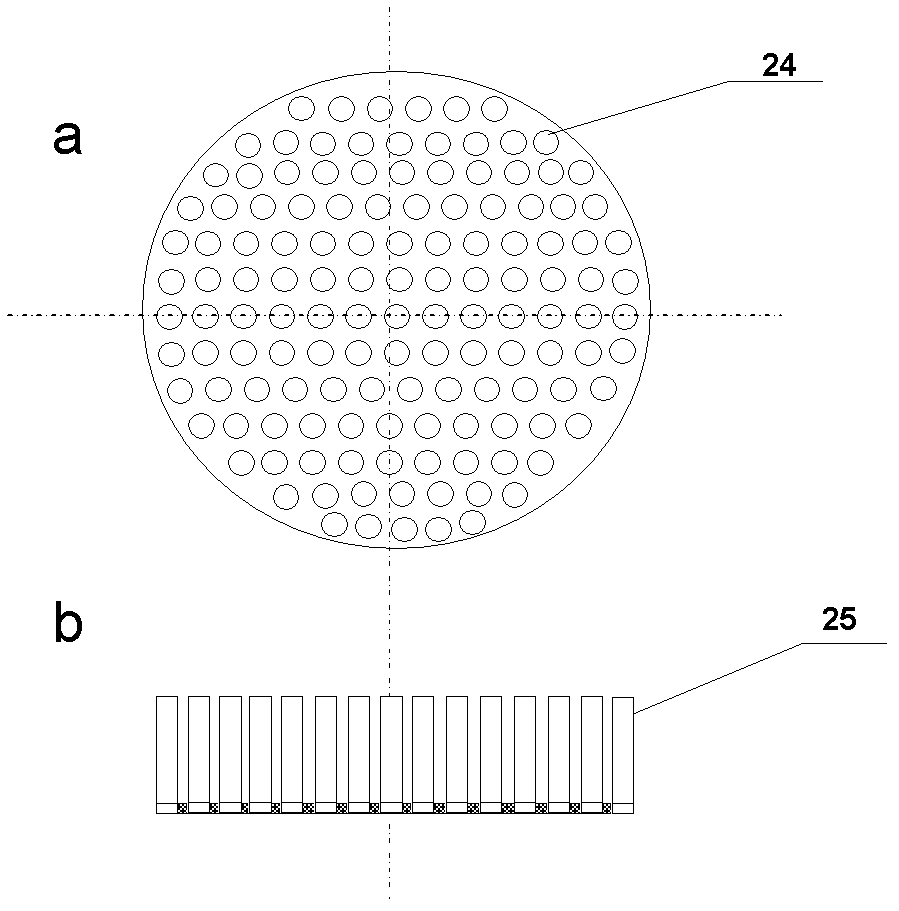

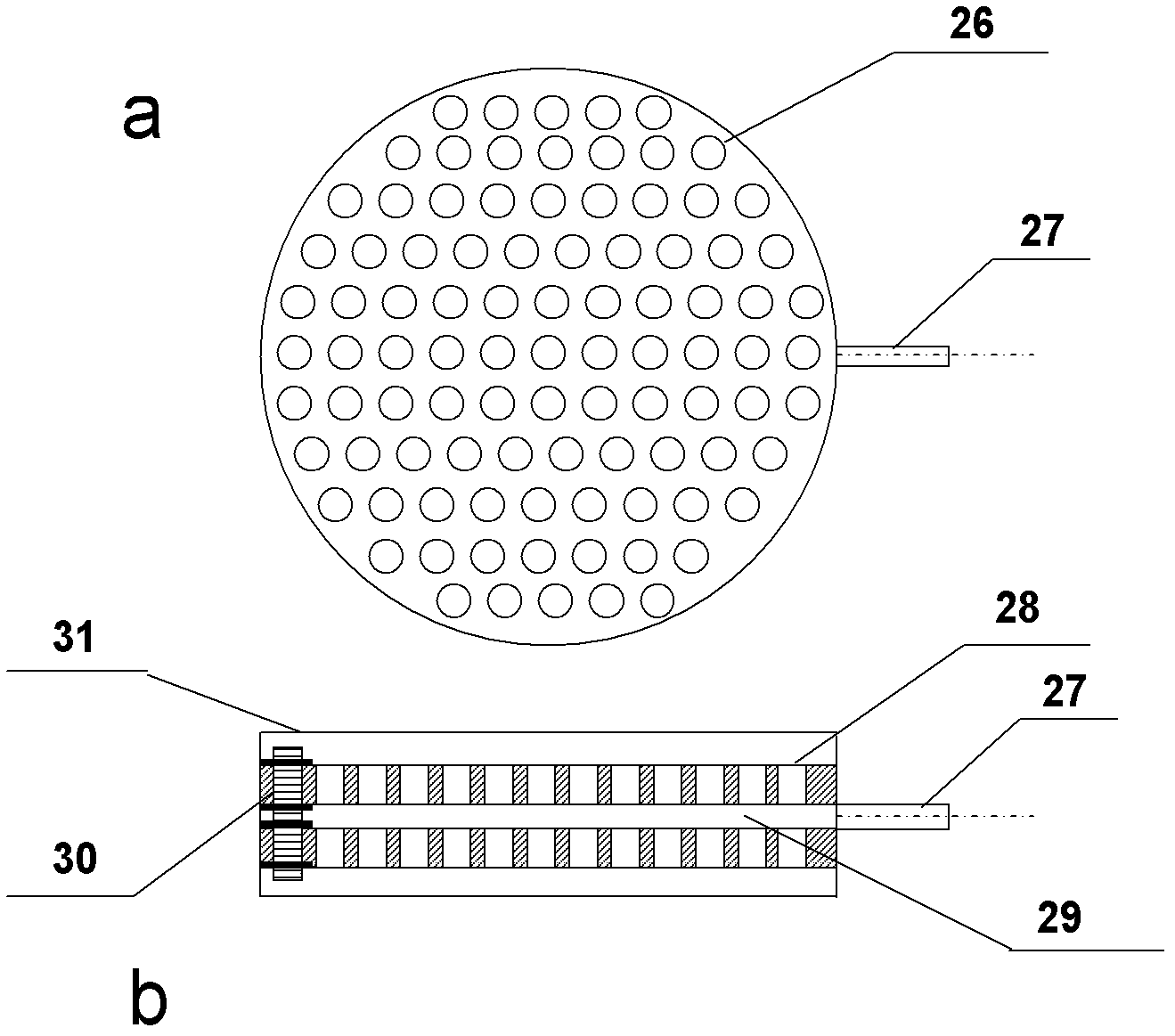

[0067] The organic phase is di-(2-ethylhexyl) phosphoric acid (P204), which is dissolved in sulfonated kerosene, and the concentration of P204 in kerosene is 1mol / L. The water phase is an aqueous solution of heavy rare earth metal ions erbium, ytterbium and lutetium, with a pH of 4-4.5 and a total concentration of rare earth metal ions of 10 mg / L. The volume of the organic phase is 10 mL, the volume of the aqueous phase to be extracted is 5 L, and the water:oil ratio is 500:1. The inner diameter of the cavity of the tower body is 50mm, and the height is 2000mm. Three sets of liquid film dispersers and bubble collecting covers are installed in the tower body, and the distance between each set is 500mm. The channel diameter of the standpipe of the liquid film disperser is 1mm, and the length of the standpipe is 5mm. The organic phase is pumped into the interlayer gap of the interlayer liquid film distributor 11 at the bottom of the tower by a diaphragm metering pump. The air p...

Embodiment 2

[0069] The organic phase is 15wt% naphthenic acid+10wt% mixed alcohol+75wt% sulfonated kerosene. The water phase is a mixed aqueous solution of yttrium, lanthanum, europium and gadolinium ions, with a pH of 4-4.5 and a total concentration of rare earth metal ions of 100 mg / L. The volume of the organic phase is 100 mL, the volume of the aqueous phase to be extracted is 100 L, and the water:oil ratio is 1000:1. The inner diameter of the cavity of the tower body is 50mm, and the height is 2000mm. Three sets of liquid film dispersers and bubble collecting covers are installed in the tower body, and the distance between each set is 500mm. The channel diameter of the standpipe of the liquid film disperser is 1.5 mm, and the length of the standpipe is 10 mm. The organic phase is pumped into the interlayer gap of the interlayer liquid film distributor 11 at the bottom of the tower by a diaphragm metering pump. The air pressure of the air cylinder connected to the tower bottom pressu...

Embodiment 3

[0071] The organic phase is partially hydrogenated monoisooctyl phosphonate (P507), which is dissolved in sulfonated kerosene, and the concentration of P507 in kerosene is 1.5mol / L. The water phase is a mixed aqueous solution of lanthanum, europium and ytterbium ions, with a pH of 4-4.5 and a total concentration of rare earth metal ions of 100mg / L. The volume of the organic phase is 100 mL, the volume of the aqueous phase to be extracted is 10 L, and the water:oil ratio is 100:1. The inner diameter of the cavity of the tower body is 50mm, and the height is 2000mm. Three sets of liquid film dispersers and bubble collecting covers are installed in the tower body, and the distance between each set is 500mm. The channel diameter of the standpipe of the liquid film disperser is 1mm, and the length of the standpipe is 10mm. The organic phase is pumped into the interlayer gap of the interlayer liquid film distributor 11 at the bottom of the tower by a diaphragm metering pump. The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com