Vertical tower tray and gas-liquid contact mass transfer equipment with same

A technology of gas-liquid contact and trays, which is applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical processes, etc. It can solve the problem of mass transfer effects and the failure of vertical spray trays to achieve normal operation, etc. problems, to achieve the effect of improving the flexibility of low-load operation, ensuring the efficiency of gas-liquid mass transfer, and improving work efficiency

Active Publication Date: 2022-01-18

CHINA PETROLEUM & CHEM CORP +1

View PDF13 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these vertical spray trays also have the following problems: the mass transfer effect of the vertical spray trays depends on the gas-liquid ratio, and the above-mentioned vertical spray trays are suitable for gas-liquid mass transfer processes with large quantities, such as dry gas During the amine liquid desulfurization process, water washing cooling process, etc., when the gas phase flow rate is insufficient (less than 60% of the normal load) or the gas volume fluctuates, the vertical spray tray will not be able to achieve normal operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0051] The comparative test data of the vertical tray according to the present invention and the traditional tray are given below.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

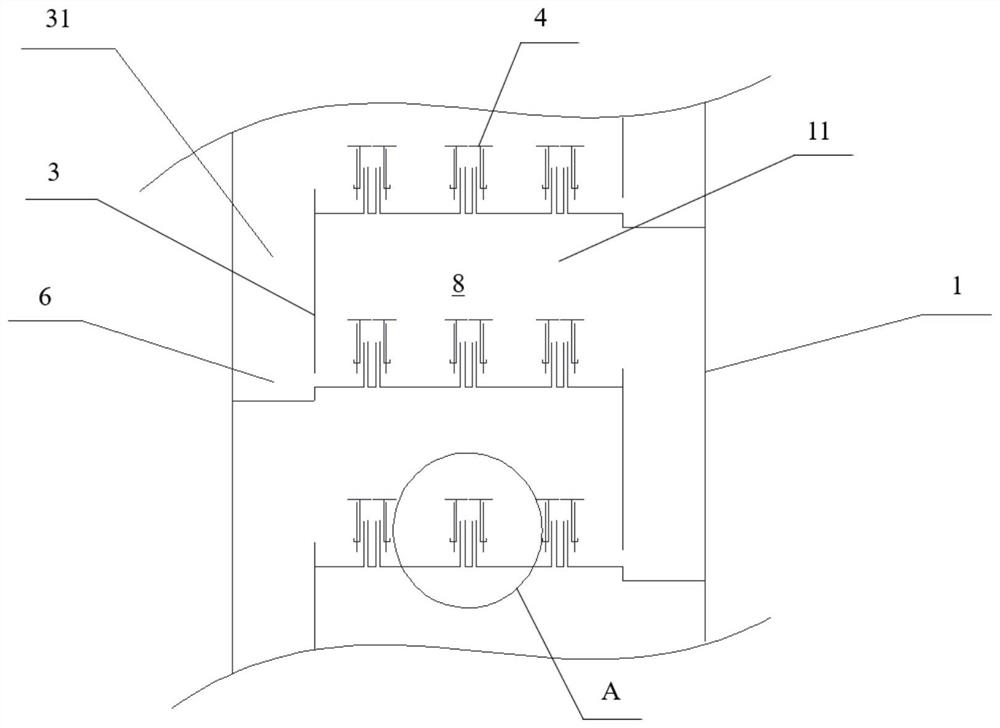

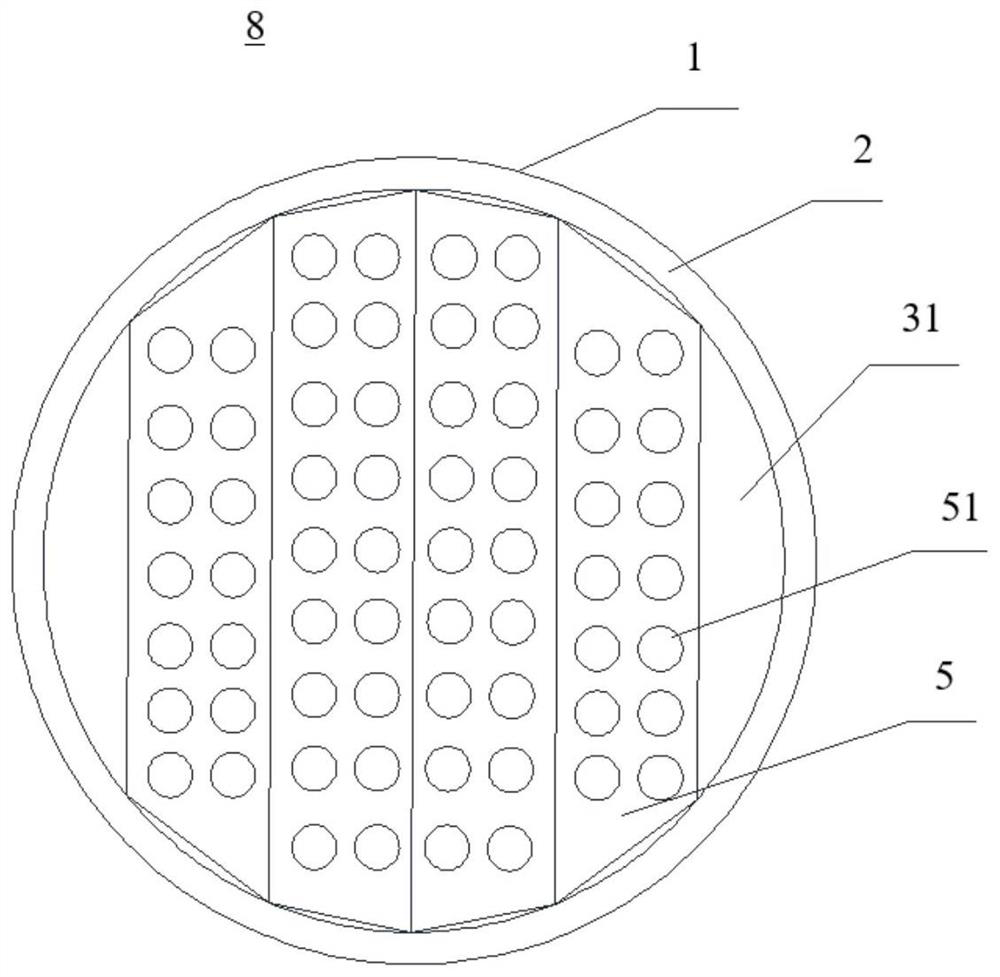

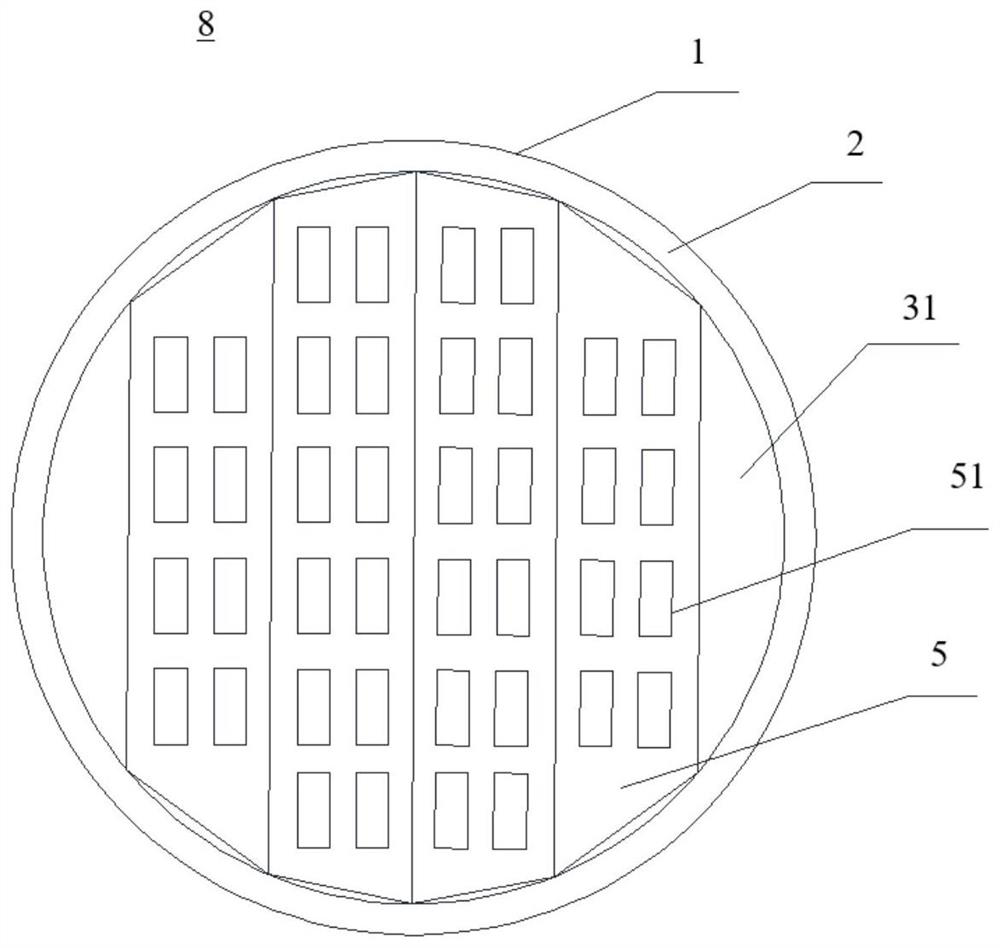

The invention provides a vertical tower tray and gas-liquid contact mass transfer equipment with the vertical tower tray. The vertical tower tray comprises: a tower plate (5), wherein the tower plate (5) is provided with a plurality of open holes (51); and a plurality of mass transfer units (4) arranged on the tower plate (5) corresponding to the plurality of open holes (51), wherein at least one mass transfer unit (4) comprises a fixed cover (42) covering the corresponding open hole (51) and a movable part (43) arranged on the fixed cover (42), a gas-liquid outlet communicated with the corresponding open hole (51) is defined between the movable part (43) and the fixed cover (42), and the movable part (43) is movably arranged relative to the fixed cover (42) so as to adjust the size of the gas-liquid outlet.

Description

technical field [0001] The invention relates to petrochemical production equipment, in particular to a vertical tray and gas-liquid contact mass transfer equipment with the vertical tray. Background technique [0002] Columns are very important equipment in the process of oil refining and chemical production. The form of the tower can be divided into plate tower and packed tower. Tray towers can be divided into sieve plate towers, floating valve towers, solid valve towers, etc. according to their internal tray forms. In the gas-liquid mass transfer process of the plate tower, the liquid phase is the continuous phase, and the gas phase is the dispersed phase. The mass transfer mode of gas in liquid is bubbling, and the degree of dispersion of gas in liquid directly determines the efficiency of gas-liquid mass transfer. [0003] At present, many plate towers use vertical jet trays. The vertical spray tray is a tray with a spray cover with a certain gap between the plate an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J19/32

CPCB01J19/32

Inventor 赵毅赵德银姚彬周勇战征崔瑞雪梁根生张菁张倩黎志敏钟荣强李鹏

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com