Sewage treatment method of a delayed coking device

A sewage treatment method and delayed coking technology, applied in water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as coking sewage treatment difficulties, and achieve strong pertinence and easy settlement Layered, low-volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

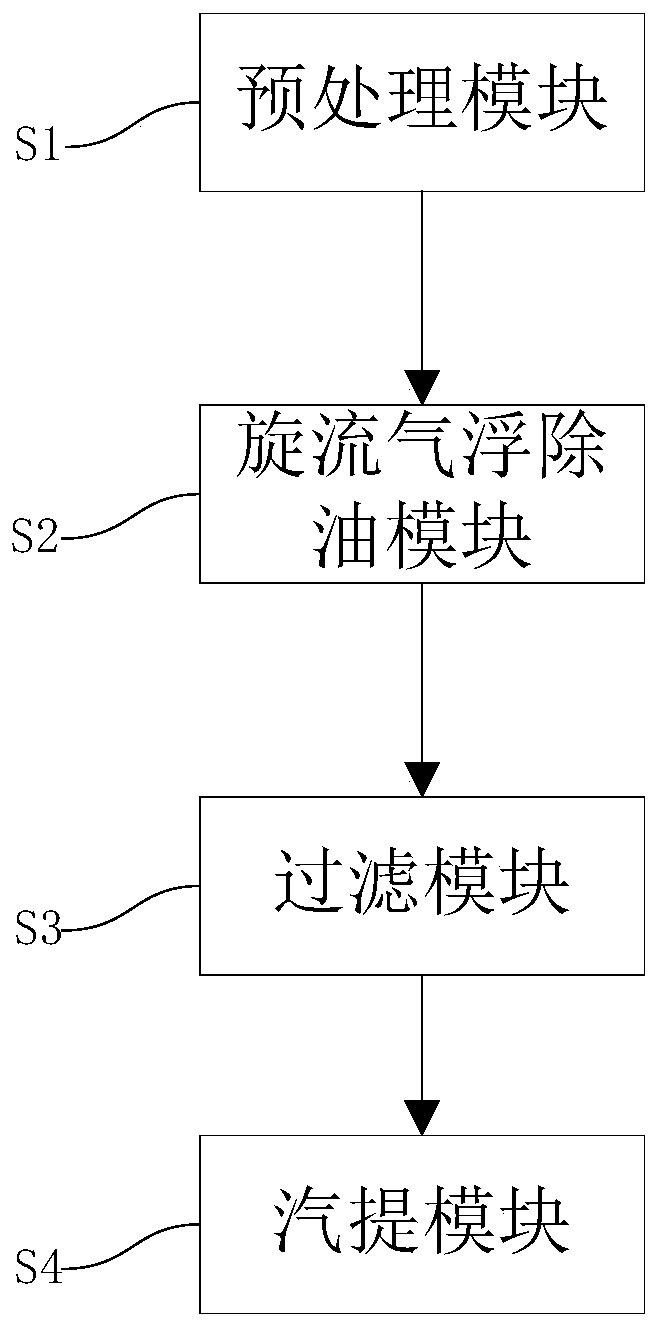

[0065] as attached figure 1 As shown, the delayed coking plant sewage treatment method of the present invention, the method is specifically as follows:

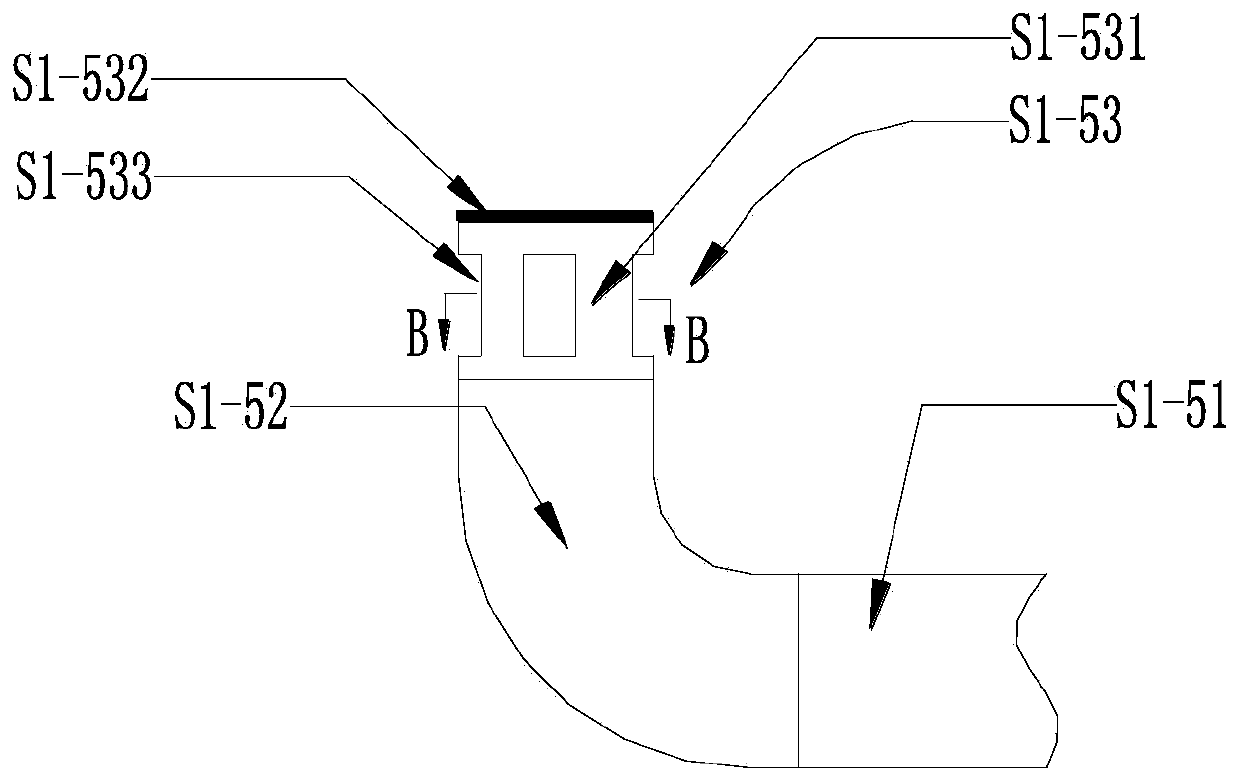

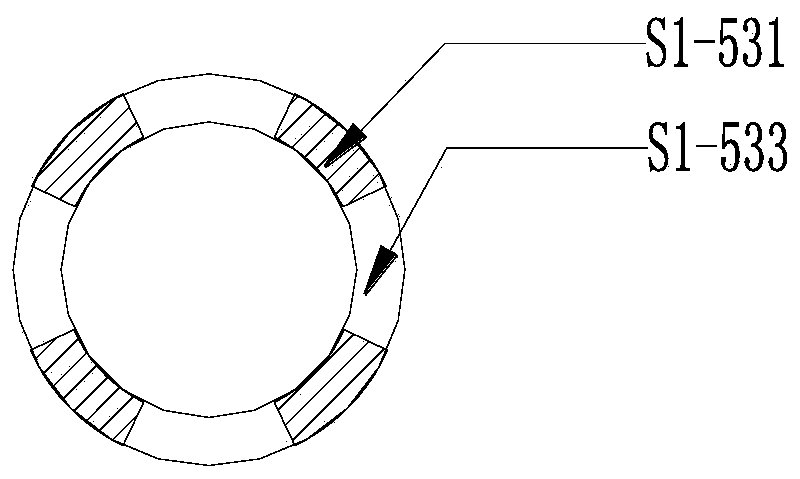

[0066] (1) Pretreatment: Inject the demulsifier with active conversion agent, high-efficiency dispersant and flocculant into the pretreatment module S1, wherein the active conversion agent adopts polyoxyethylene polyoxypropylene polyether with multi-branch structure, The addition amount is 50-100mg / L; the high-efficiency dispersant uses polyacrylamide cationic polymer copolymer, and the addition amount is 0-5mg / L; the flocculant uses polyaluminosilicate, and the addition amount is 0-50mg / L; The temperature in the treatment module is 40-90°C. After the sewage is mixed with a demulsifier, it is buffered, settled and stratified in the pretreatment module S1, and then discharged to the downstream for treatment; as attached figure 2As shown, the pretreatment module S1 includes a raw water tank S1-1 and a waste oil tank S1-2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com