Device for continuously and rapidly defoaming high-viscosity fluid

A high-viscosity, fluid technology, applied in the direction of foam dispersion/prevention, etc., can solve the problems of long static vacuum degassing time, non-continuous degassing, poor equipment flexibility, etc., to achieve high-quality degassing, rapid degassing, and production loss and the effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment is further described below in conjunction with accompanying drawing of the present invention:

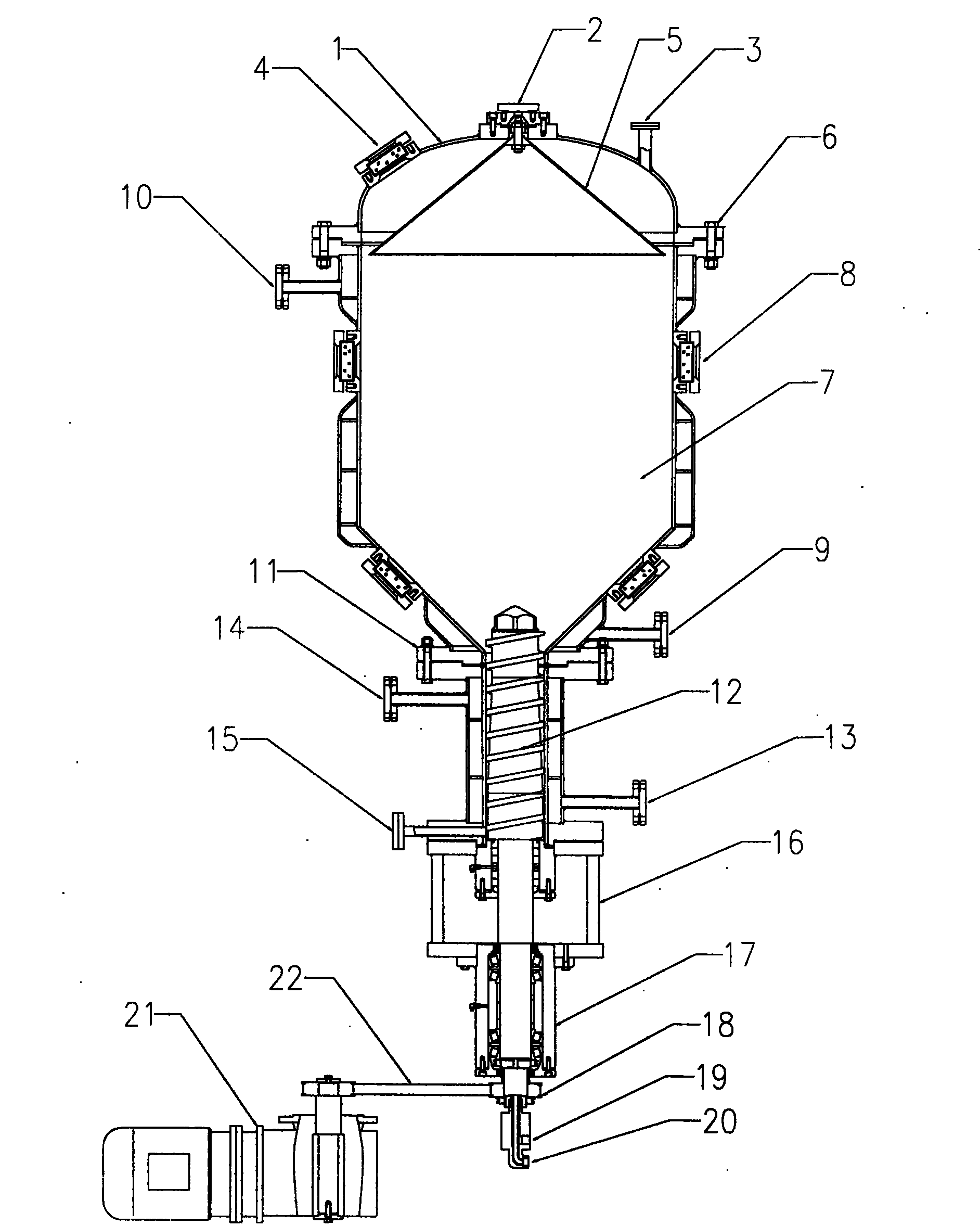

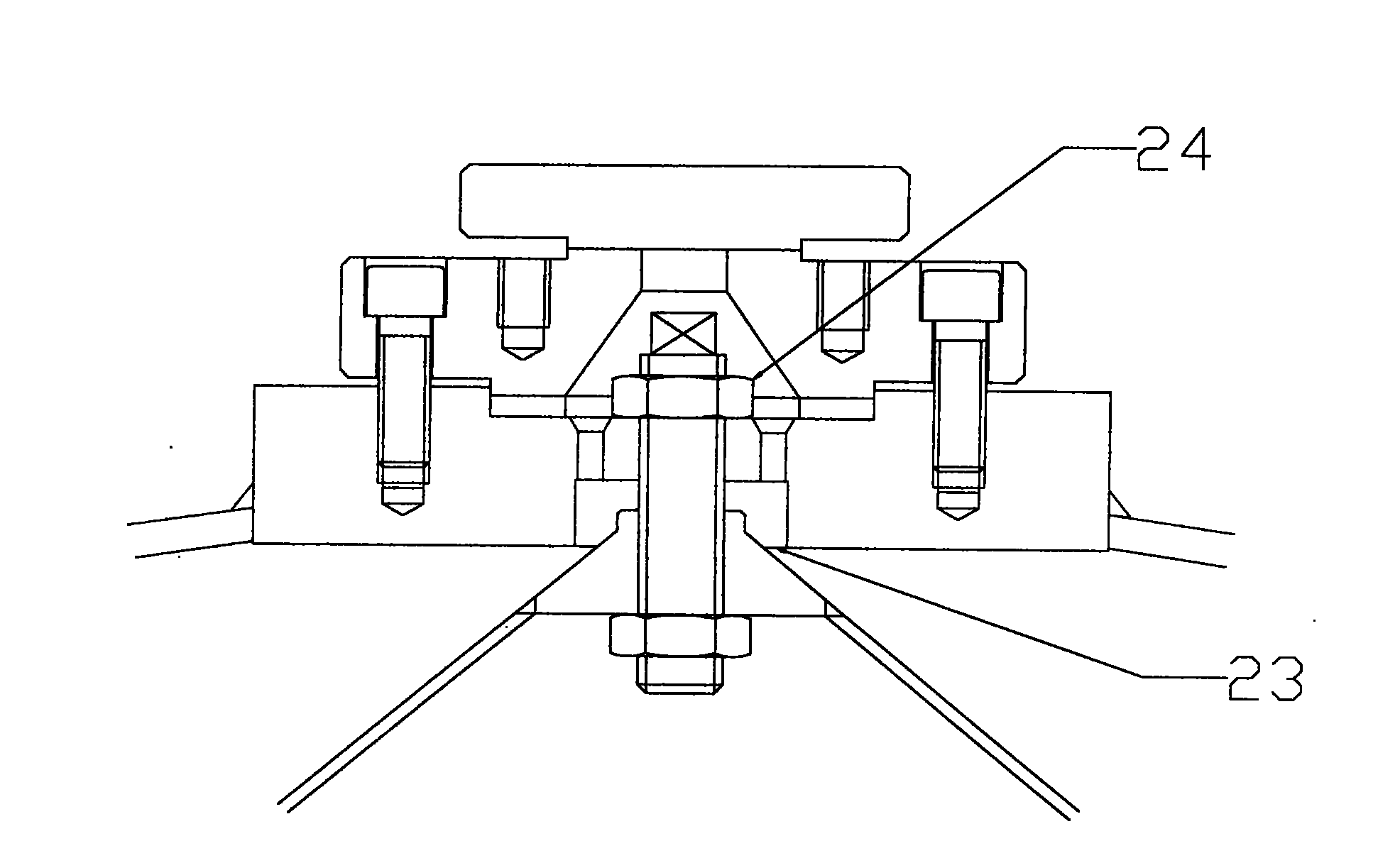

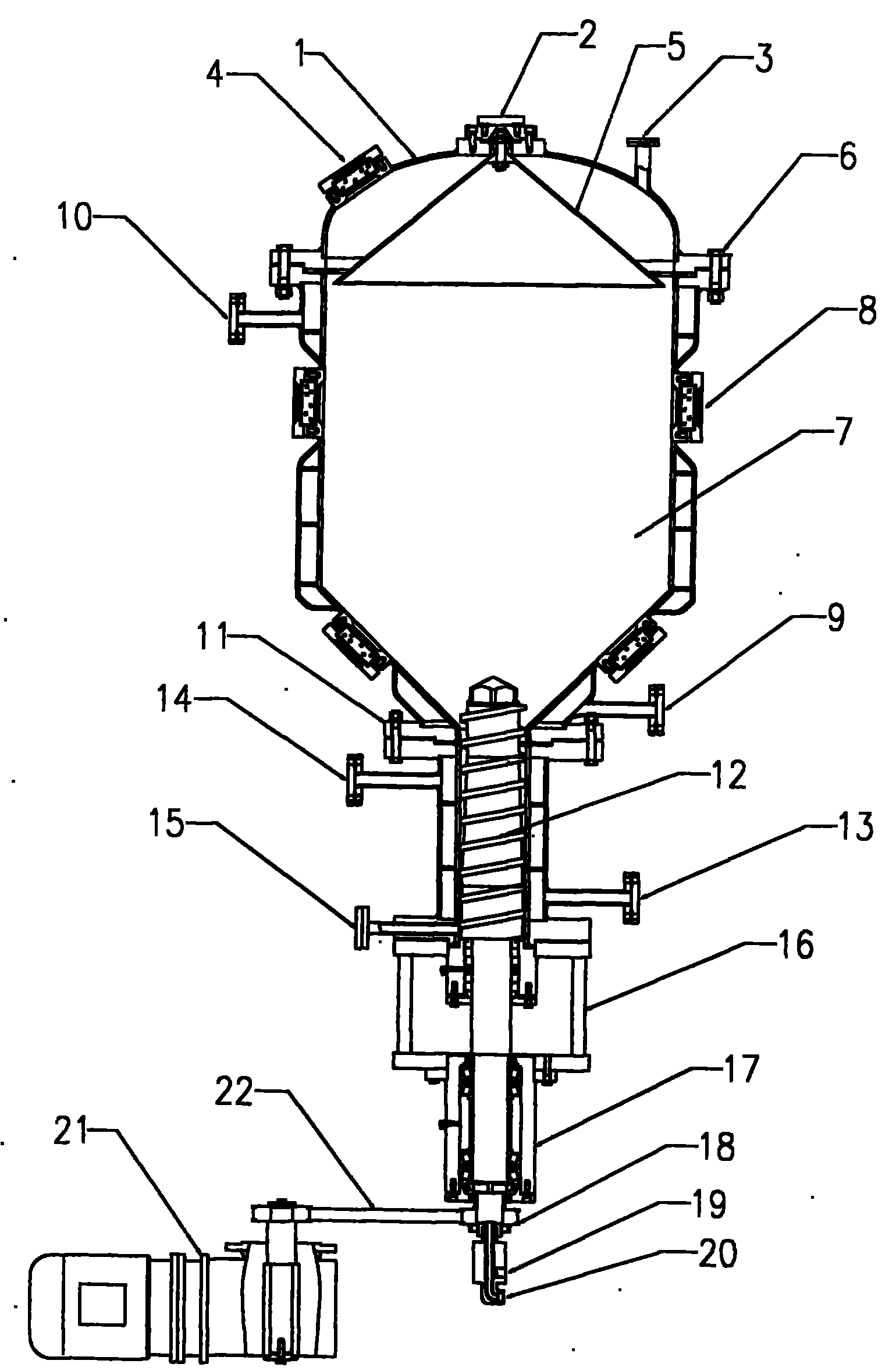

[0022] Such as figure 1 , 2 As shown, the embodiment of the present invention consists of a head 1, a feed port 2, a vacuum suction port 3, a head sight glass 4, an umbrella 5, a head flange 6, a vacuum kettle 7, a kettle body sight glass 8, and a kettle body. Body jacket medium inlet 9, kettle body jacket medium outlet 10, outlet flange 11, screw 12, screw cooling medium inlet 13, screw cooling medium outlet 14, material outlet 15, sealing device 16, screw stabilizing device 17 , transmission device 18, cooling medium outlet 19 in the screw, cooling medium inlet 20 in the screw, motor 21, transmission belt 22, slit 23, and slit adjustment device 24.

[0023] The head 1 is located on the upper part of the vacuum kettle 7, and is connected to the vacuum kettle 7 through the head flange 6. The diameter of the vacuum kettle 7 is 400-1200 mm, the length is 700-1500 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com