Method for preparing thin-diameter zirconium oxide fibers and fiber board thereof

A technology of zirconia fiber and fine diameter, which is applied in the direction of fiberboard, fiber treatment, stretch spinning, etc. It can solve the problems of difficult precise control of thickness, uneven thickness of fiberboard, uneven upper surface, etc., and achieve low cost and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

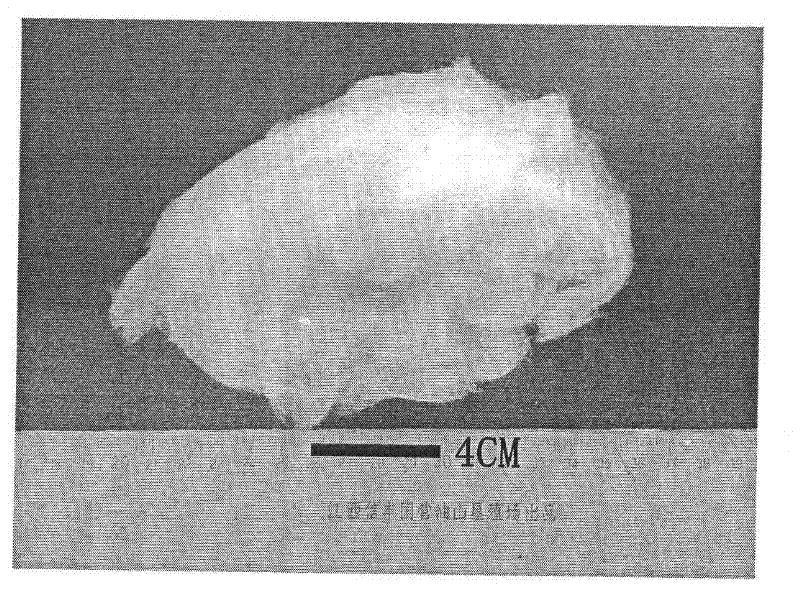

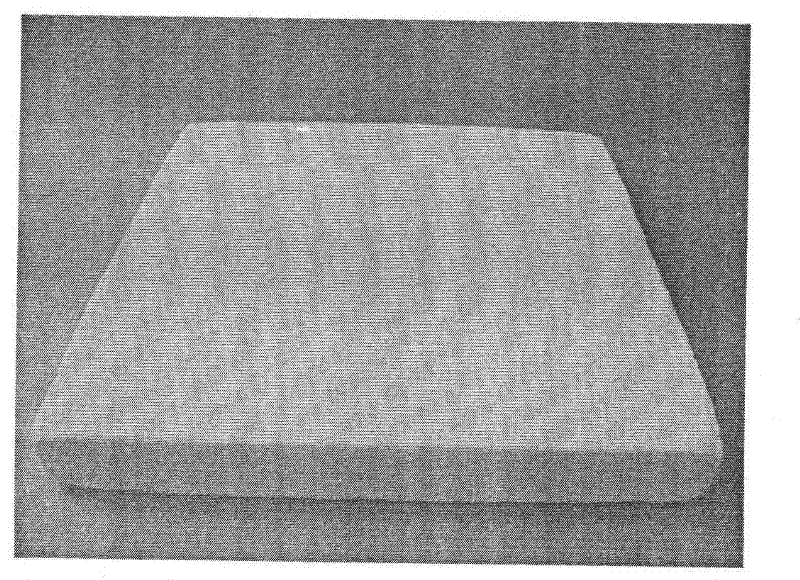

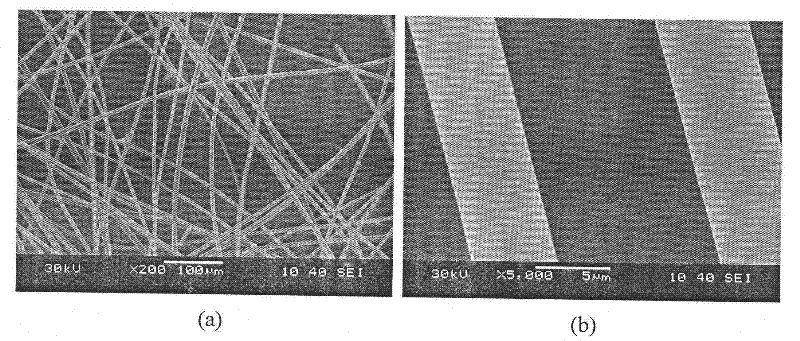

Examples

preparation example Construction

[0024] The preparation method of fine-diameter zirconia fiber and fiberboard thereof of the present invention specifically comprises the following steps:

[0025] (1) One-step reaction to prepare polyzirconium sol spinning solution

[0026] According to the ZrO in the reaction system 2 : Glacial acetic acid: the molar ratio of water is the ratio of 1: 2~3: 15~25, takes the zirconium basic carbonate (molecular formula ZrOCO 3 ·nH 2 O, ZrO 2 Content 38 ~ 42wt%), and measure the corresponding volume of glacial acetic acid and water, dilute the glacial acetic acid in water, and mix the acetic acid aqueous solution and basic zirconium carbonate at 70°C ~ 80°C under stirring and pumping conditions, and react Form zirconium basic acetate with CO 2 The gas escapes, and the basic zirconium acetate undergoes further hydrolysis-polycondensation reaction to form a Zr-O-Zr chain polymer with acetate as the side group. After the solid is completely dissolved and the reaction solution be...

Embodiment 1

[0035] (1) One-step reaction prepares polyzirconium sol spinning solution:

[0036] According to the ZrO in the reaction system 2 : Glacial acetic acid: the molar ratio of water is the ratio of 1: 2.5: 20, and the zirconium basic carbonate (molecular formula ZrOCO 3 ·nH 2 O, ZrO 2 Content 40.6wt%) 1kg, and measure 474mL glacial acetic acid and 1188mL water, dilute glacial acetic acid in water, under 75 ℃, under the condition of stirring and pumping air, the aqueous solution of acetic acid and basic zirconium carbonate are mixed and reacted, until all solids are dissolved , After the reaction solution becomes transparent, the polyzirconium aqueous solution is obtained, and according to the composition ratio requirements of the fully stable cubic phase zirconia, that is, ZrO 2 : Y 2 o 3 The mol ratio is the ratio of 92:8, in the above-mentioned polyzirconium aqueous solution, add 220g phase stabilizer raw material yttrium nitrate (Y(NO 3 ) 3 ·6H 2 (0), stirring to make i...

Embodiment 2

[0044] (1) One-step reaction prepares polyzirconium sol spinning solution:

[0045] According to the ZrO in the reaction system 2 : glacial acetic acid: the molar ratio of water is the ratio of 1: 3: 25, and the zirconium basic carbonate (molecular formula ZrOCO 3 ·nH 2 O, ZrO 2 Content 41.4wt%) 1kg, and measure 578mL glacial acetic acid and 1515mL water, dilute glacial acetic acid in water, under 70 ℃, under the condition of stirring and pumping air, acetic acid aqueous solution and basic zirconium carbonate are mixed and reacted to obtain polyzirconium aqueous solution, According to the composition ratio requirements of fully stable cubic zirconia, that is, ZrO 2 : Y 2 o 3 The mol ratio is the ratio of 91:9, in the above-mentioned polyzirconium aqueous solution, add 255g phase stabilizer raw material yttrium nitrate (Y(NO 3 ) 3 ·6H 2 (0), stirring to make it dissolve, and then distilling under reduced pressure at 70°C to remove excess moisture until obtaining a polyz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com