Gas integrated unit

An integrated unit and gas technology, applied in the direction of electrical components, gaseous chemical plating, semiconductor/solid-state device manufacturing, etc., can solve the problem of enlarged base space and achieve the effect of reducing the base space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

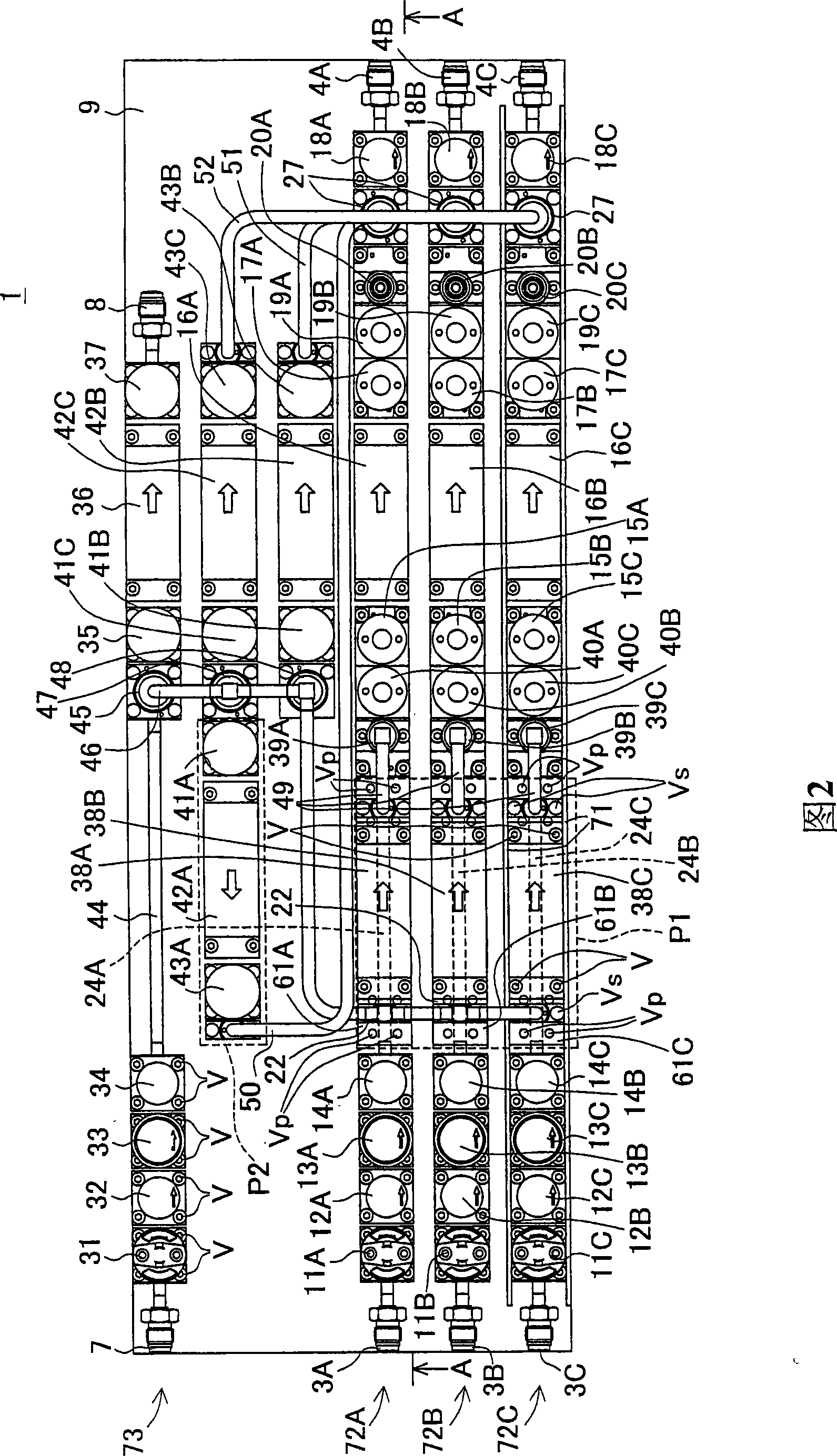

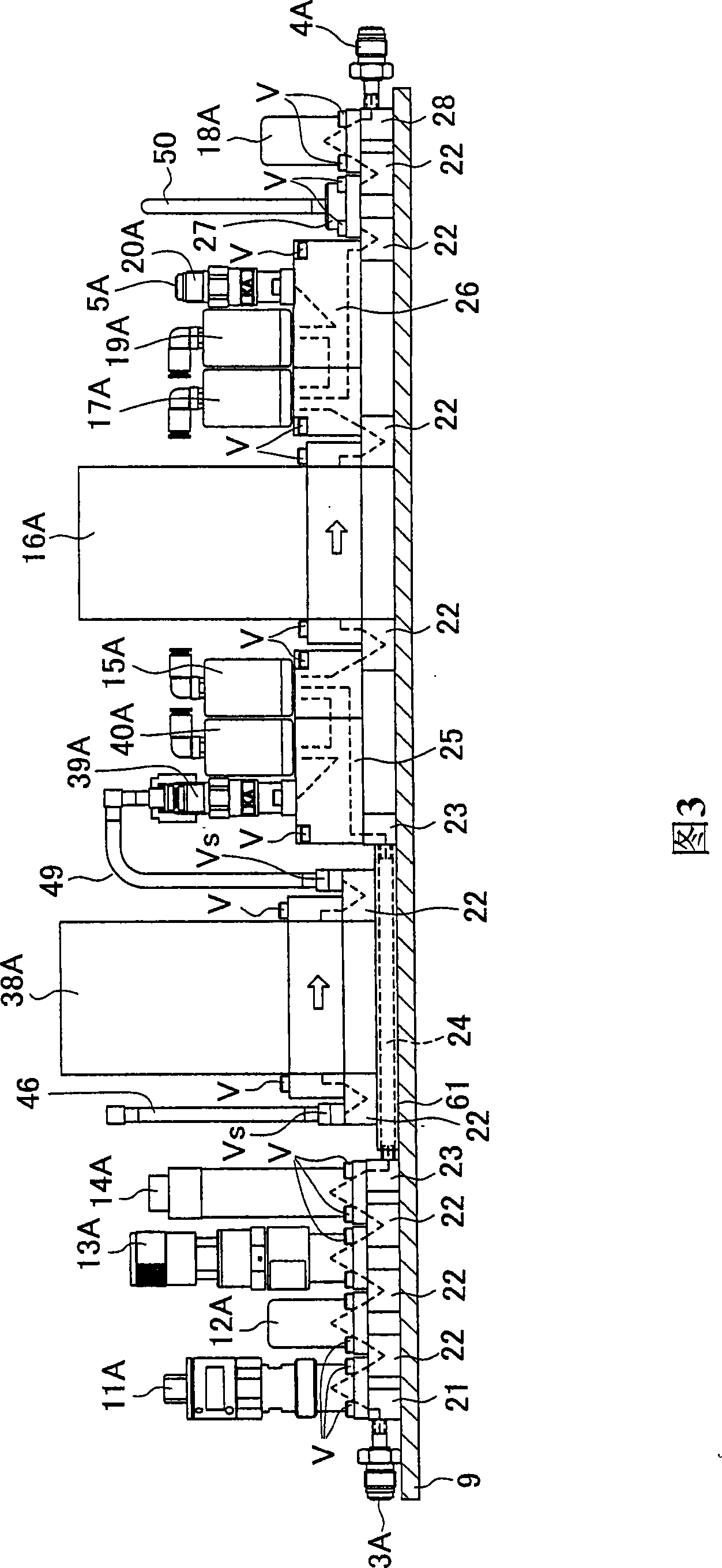

[0024] Next, one embodiment of the gas integration unit of the present invention will be described with reference to the drawings.

[0025] (circuit description)

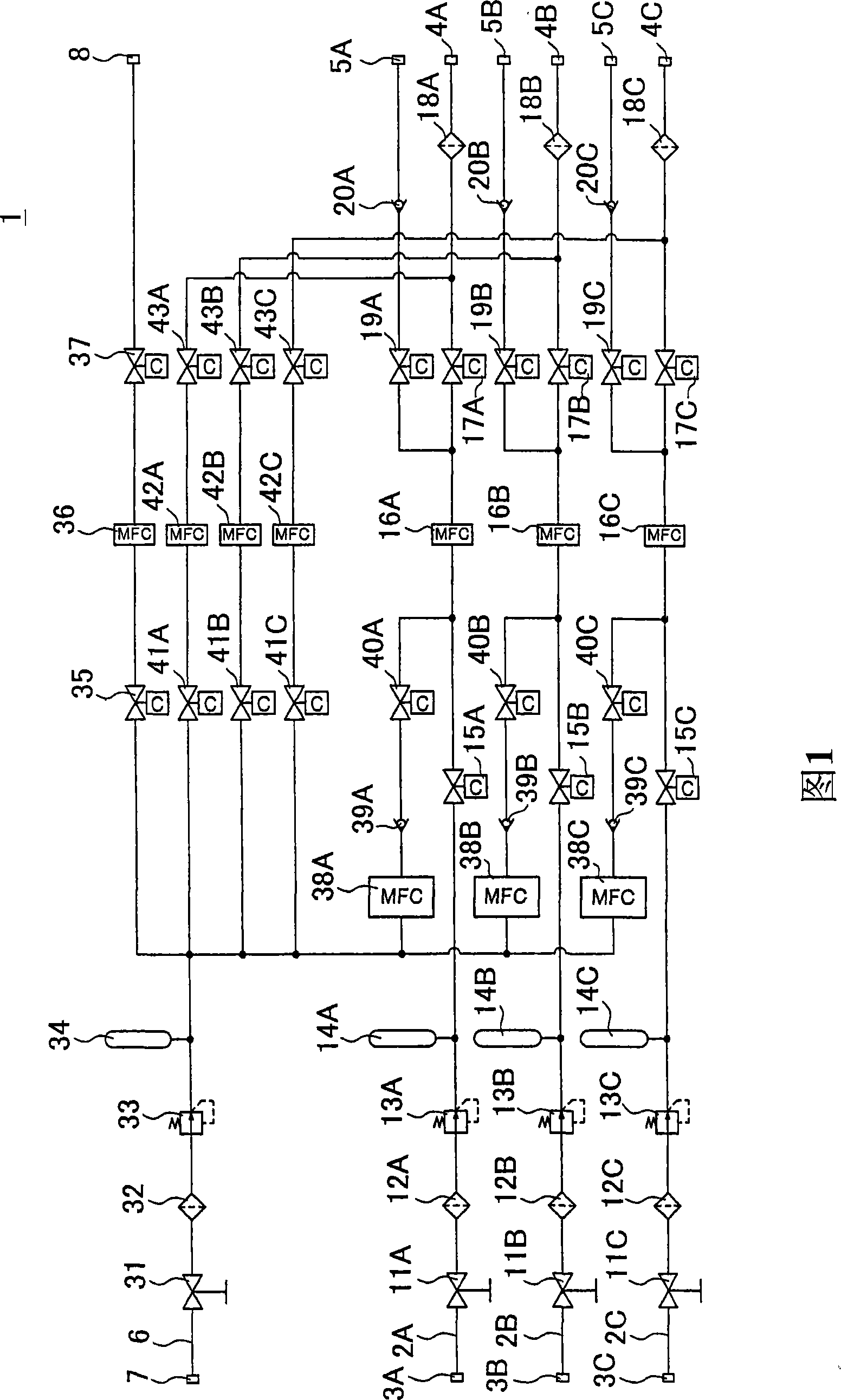

[0026] figure 1 is a circuit diagram of the gas integration unit 1.

[0027] The gas integration unit 1 is arranged between an unillustrated gas tank and an unillustrated processing chamber. In order to supply a certain amount of working gas from the unillustrated gas tank to the unillustrated processing chamber each time, a second One to the third process gas pipelines 2A, 2B, 2C. Furthermore, the gas integration unit 1 is provided with a purge gas line 6 for cleaning the first to third process gas lines 2A, 2B, and 2C.

[0028] A plurality of fluid control means are provided in the first to third process gas lines 2A, 2B, and 2C. The manual valves 11A, 11B, and 11C are connected to unillustrated gas tanks through operating gas inlets 3A, 3B, and 3C. Manual valves 11A, 11B, 11C are connected to first process s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com