Seed crystal splicing structure for ingot casting

A seed crystal and ingot casting technology is applied in the field of seed crystal splicing structure for ingot casting, which can solve the problems affecting the quality of single crystal ingots, the deterioration of process tolerance performance, and the splicing deformation of seed crystals, so as to improve the photoelectric conversion efficiency, The effect of increasing the area ratio of single crystal and improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

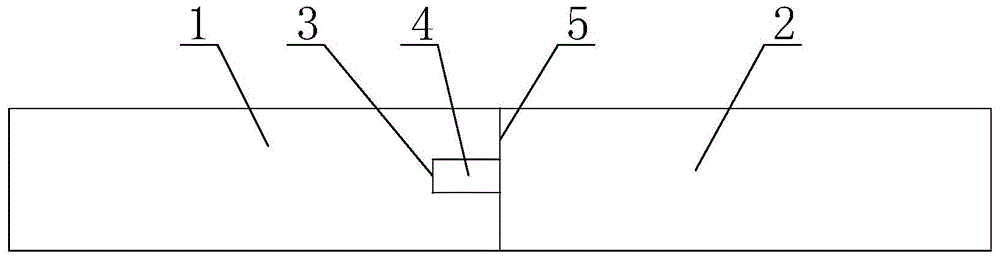

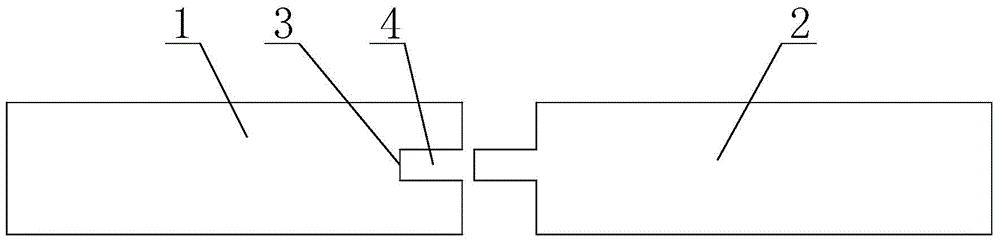

[0019] Such as figure 1 , figure 2 As shown, the splicing structure of seed crystals for ingot casting in the embodiment of the present invention includes elongated plate-shaped seed crystal blocks 1 and 2 spliced with each other, and the splicing surface 5 between adjacent seed crystal blocks 1 and 2 is perpendicular to the bottom of the crucible and the seed crystal block 1 on one side of the splicing surface 5 is provided with a strip-shaped rectangular groove 3, and the seed crystal block 2 on the other side of the splicing surface 5 has a long strip-shaped groove 3 suitable for insertion into the rectangular groove 3. The rectangular bump 4, the rectangular groove 3 and the rectangular bump 4 have a rectangular cross-section. After the adjacent seed crystal blocks 1 and 2 are spliced, the rectangular bump 4 is inserted into the rectangular groove 3 and the gap between the splicing surfaces 5 is less than 0.5 mm. The gap between the bump 4 and the groove 3 is not great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com