Front-end weight block of tractor and manufacturing method thereof

A tractor and front-mounted technology, applied in the directions of wheel counterweight, body, body stability, etc., can solve the problems of high manufacturing cost, aesthetic appearance and rough surface affecting the overall shape of the tractor, and achieve low manufacturing cost, saving metal raw materials, and appearance. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

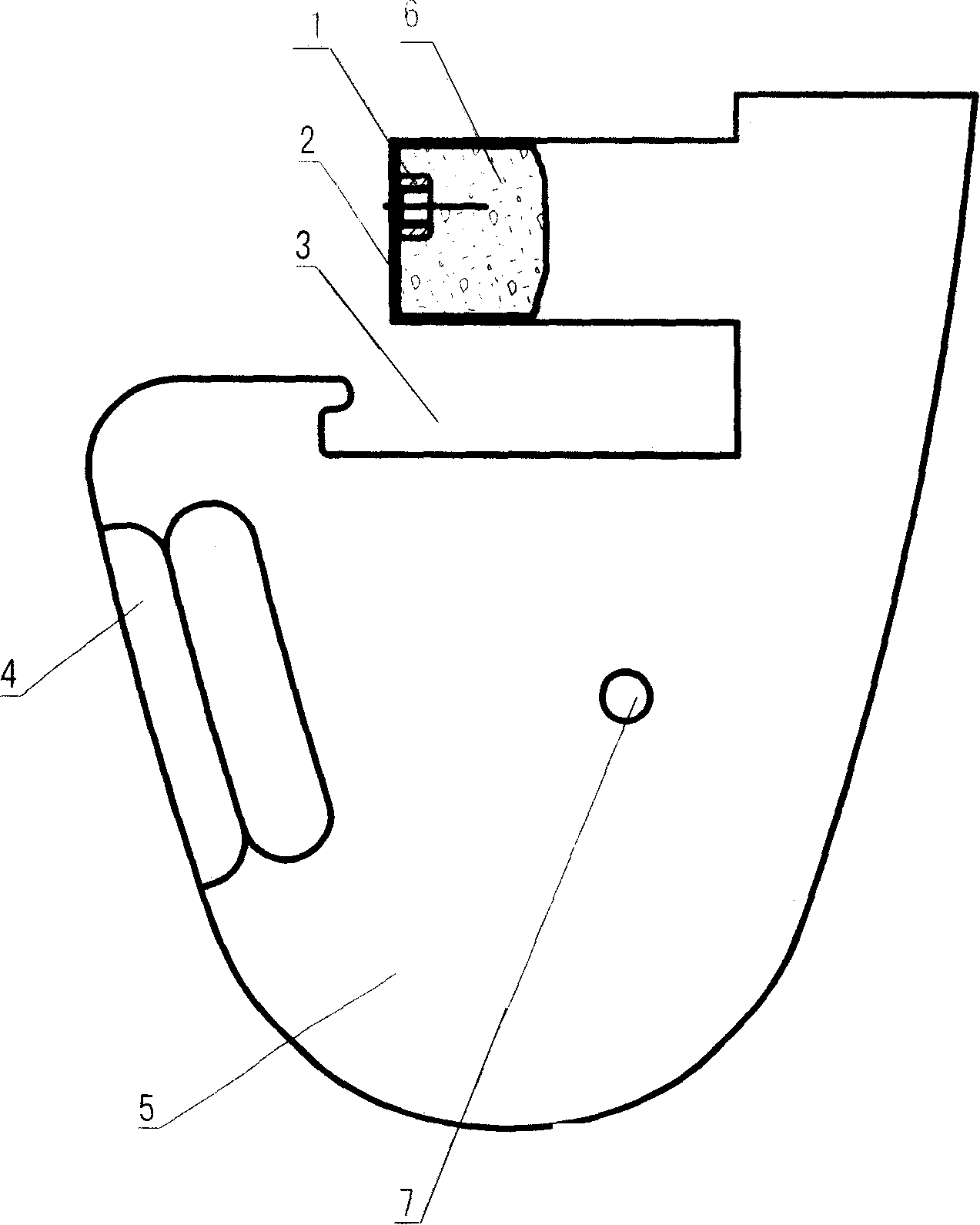

[0016] Contains a shell 5, the shell 5 has a through groove 3 that engages with the front hanging plate of the tractor and a mounting surface 2 for fixing the hanging plate, the inner cavity of the shell 5 is filled with a counterweight material 6, and the shell 5 is stamped from two steel plates Formed and then welded, the counterweight material 6 filled in the inner cavity of the shell 5 includes 80% by weight of iron ore, 9% by weight of tailings powder, 5% by weight of cement and 6% water. The overall shape of the shell 5 is a smooth arc surface, and the shell 5 also has a mounting hole 7, and a portable handle 4 is arranged on the shell 5. A fixed nut 1 is fixedly connected below the mounting surface 2 in the inner cavity of the housing 5, and the screw passes through the hole on the hanging plate and is fixedly connected with the fixing nut 1, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com