Wheel weight assembly

一种车轮、组件的技术,应用在农用拖拉机或类似车辆的配重组件领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

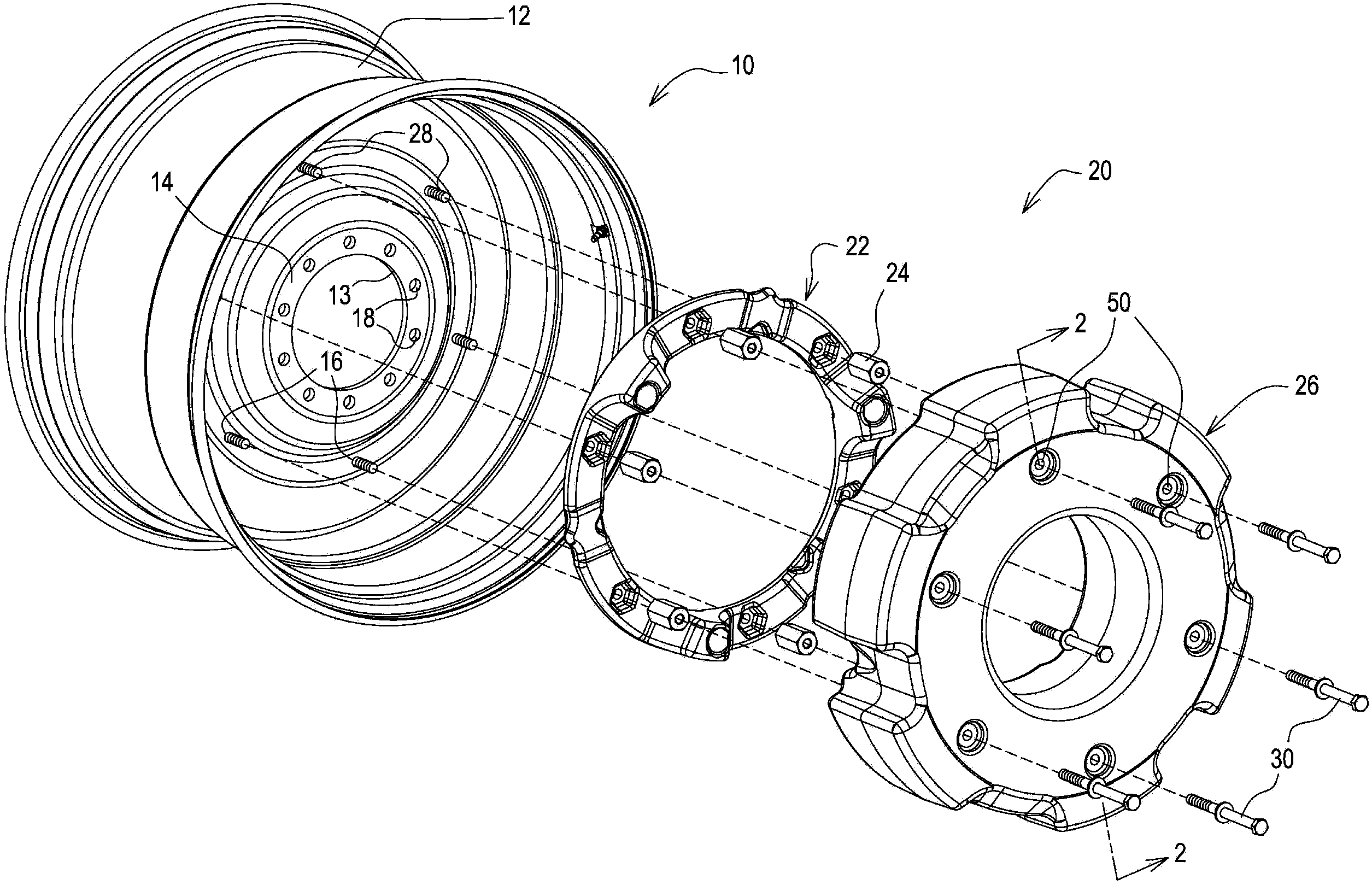

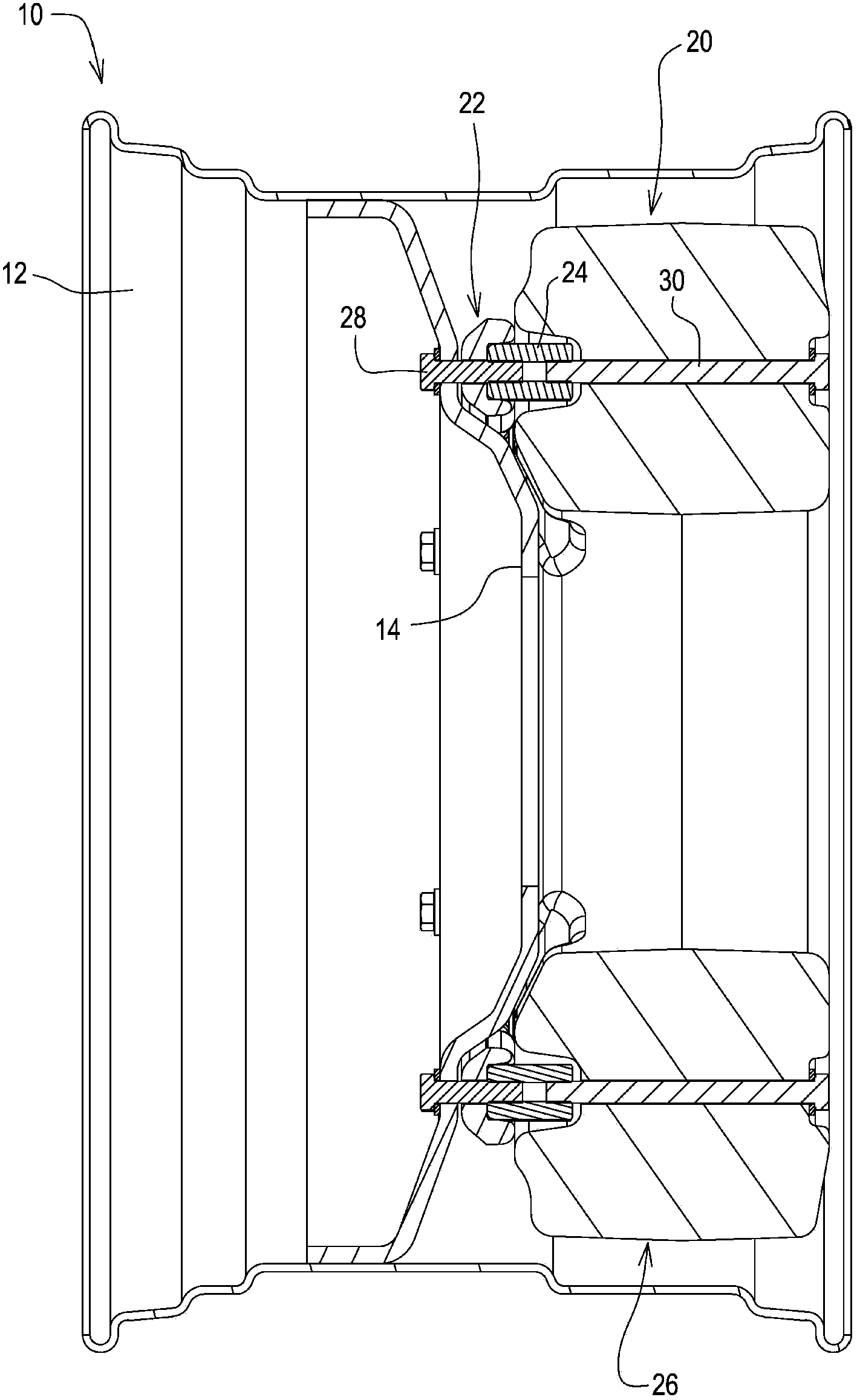

[0012] refer to figure 1 with figure 2 , the vehicle wheel 10 includes a rim 12 and a central disc portion 14 . A pneumatic tire (not shown) is mounted on the rim 12 as is well known in the art. The central disc portion 14 includes a central hole 13 , an inner set of hub mounting holes 18 and an outer set of counterweight mounting holes 16 . The wheel weight assembly 20 includes an annular inner or primary weight 22 , a set of nut members 24 , an outer weight 26 , a set of inner bolts 28 and a set of outer bolts 30 .

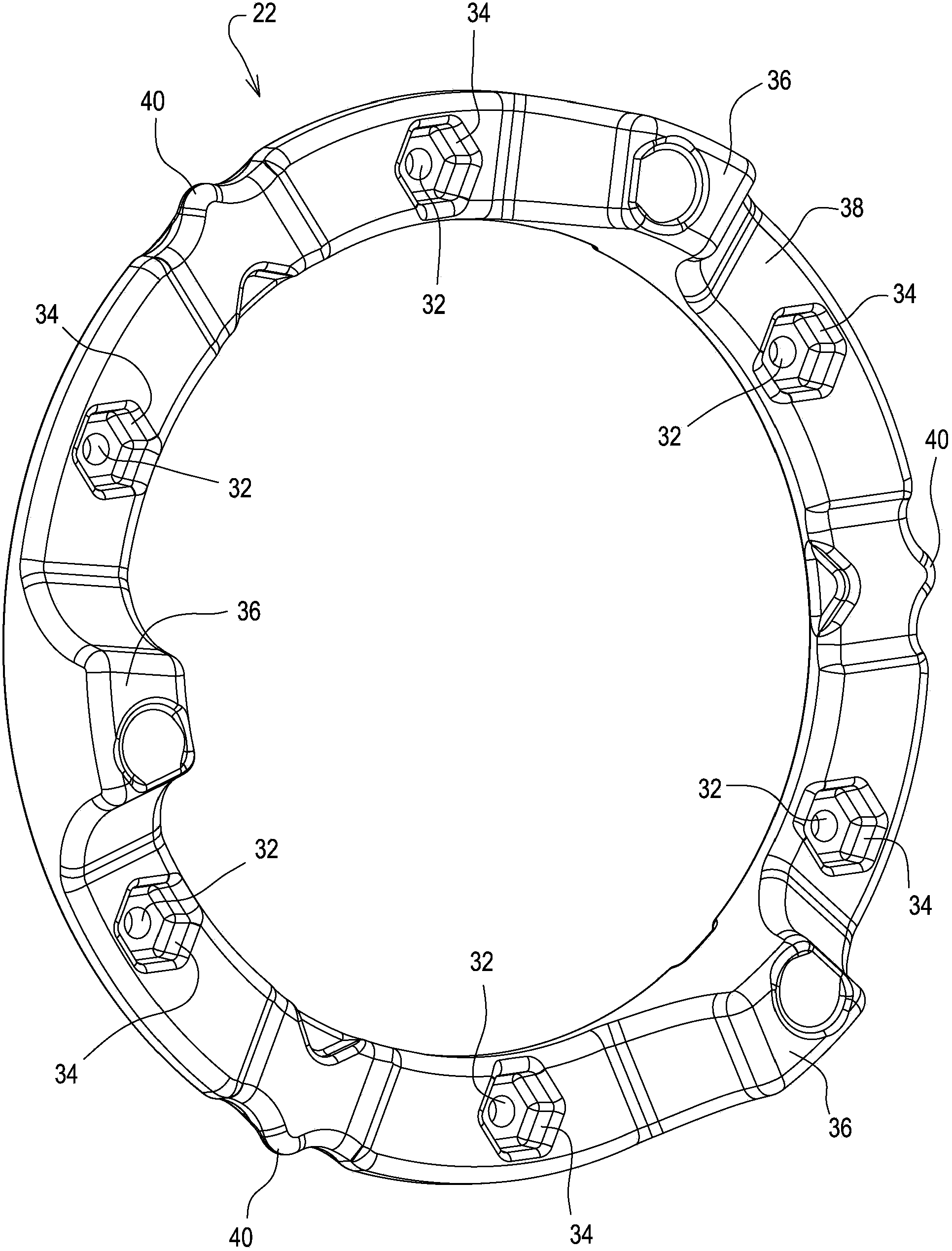

[0013] see now figure 1 , 2, 3 and 4, the initial counterweight 22 is annular, and is mounted to be in contact with the wheel disc portion 14 . The initial weight 22 has a plurality of mounting holes 32 extending axially therethrough. The hole 32 is aligned with the hole 16 of the wheel disc 14 . Surrounding each hole 32 is a recess or recess 34 of polygonal shape, preferably hexagonal or hexahedral, opening axially outwards. A plurality of spaced apart ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com