Automotive adhesion type balancing block and preparation process thereof

A balance weight and bonding technology, applied in the direction of adhesive, wheel weight, adhesive type, etc., can solve the problems of inaccurate adjustment of wheel balance, poor flexibility of balance weight, and easy corrosion of iron balance weight. To achieve the effect of improving the anti-rust effect, preventing peeling or lifting, and excellent anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

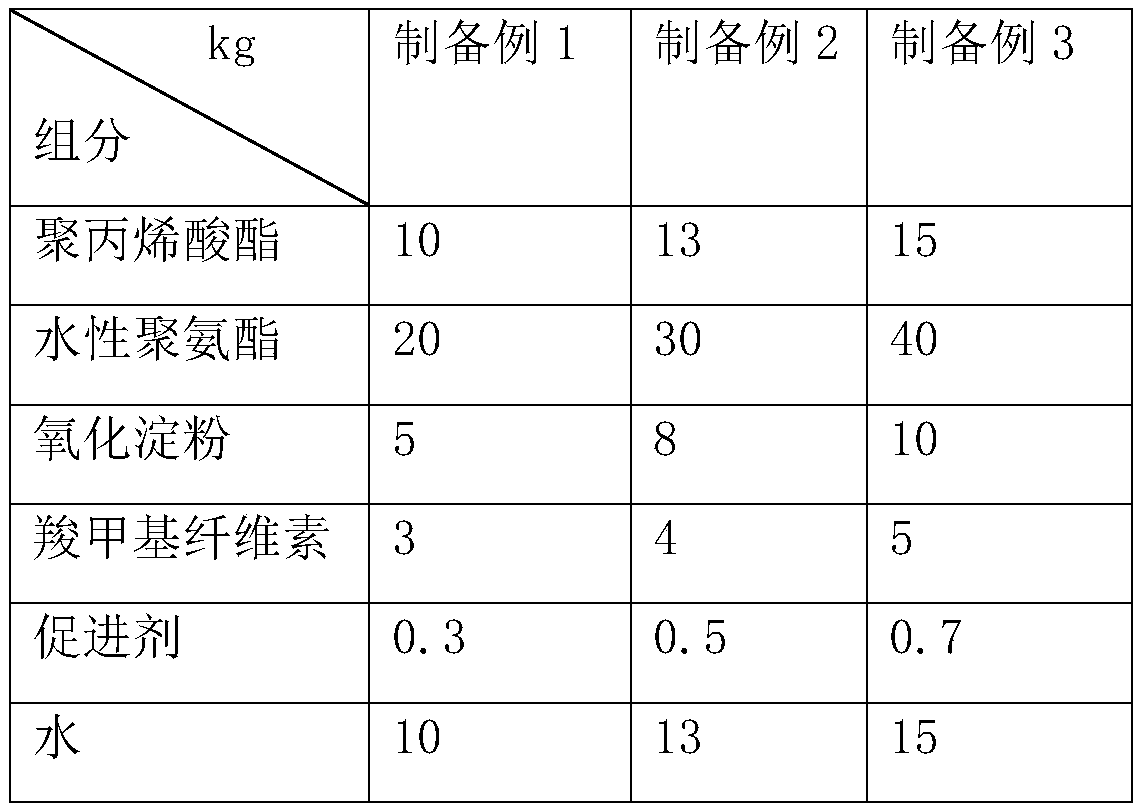

[0042] Preparation Example 1: According to the ratio in Table 1, mix 20kg of water-based polyurethane, 10kg of polyacrylate, 5kg of oxidized starch, 3kg of carboxymethyl cellulose and 10kg of water evenly, stir at a speed of 200r / min, heat up to 70°C and reflux 3h, slowly add the accelerator, continue to reflux for 3h, cool to obtain the viscose, the relative molecular weight of the water-based polyurethane is 5000g / mol, the accelerator is organic sodium carboxylate, 2,4-bis Chlorobenzenediazonium compounds and potassium dichromate.

[0043] The raw material ratio of adhesive in table 1 preparation example 1-3

[0044]

preparation example 2

[0045] Preparation example 2: According to the ratio in Table 1, mix 30kg water-based polyurethane, 13kg polyacrylate, 8kg oxidized starch, 4kg carboxymethyl cellulose and 13kg water evenly, stir at a speed of 300r / min, heat up to 80°C and reflux 2.5h, slowly add accelerator, continue to reflux for 3.5h, cool to obtain adhesive, the relative molecular weight of water-based polyurethane is 11500g / mol, the accelerator is organic sodium carboxylate, 2,4 -Dichlorobenzenediazo compound and potassium dichromate.

preparation example 3

[0046] Preparation Example 3: According to the ratio in Table 1, mix 40kg water-based polyurethane, 15kg polyacrylate, 10kg oxidized starch, 5kg carboxymethyl cellulose and 15kg water evenly, stir at a speed of 400r / min, heat up to 90°C and reflux 2h, slowly add the accelerator, continue to reflux for 4h, cool to obtain the viscose, the relative molecular weight of the water-based polyurethane is 15000g / mol, the accelerator is organic sodium carboxylate, 2,4-bis Chlorobenzenediazonium compounds and potassium dichromate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Relative molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com