Small steel wheel balance blocks, manufacturing method thereof and stamping die

A technology for stamping dies and balance blocks, which is applied to manufacturing tools, wheel counterweights, forming tools, etc., can solve problems such as large collapse angle and affect the quality of parts section, and achieve the effect of improving production efficiency and solving section collapse angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

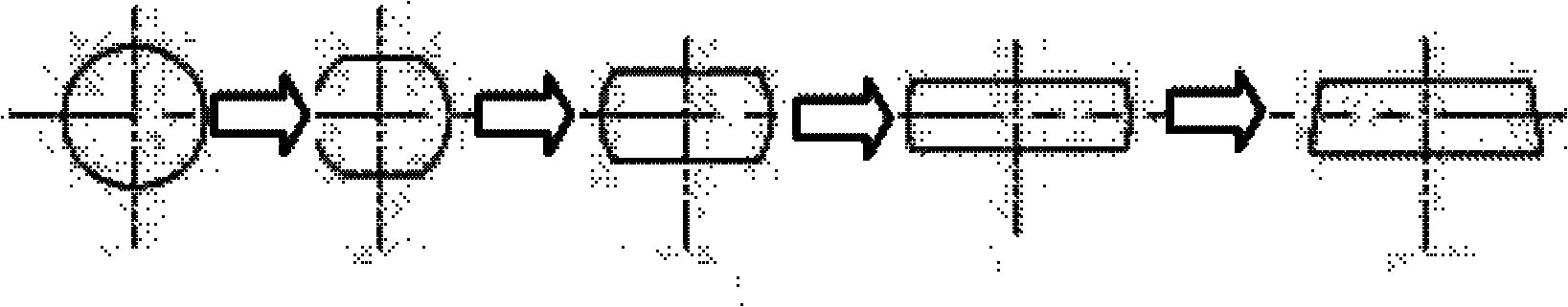

[0028] Please refer to Figure 1, figure 2 , image 3 , in order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments and in conjunction with the accompanying drawings:

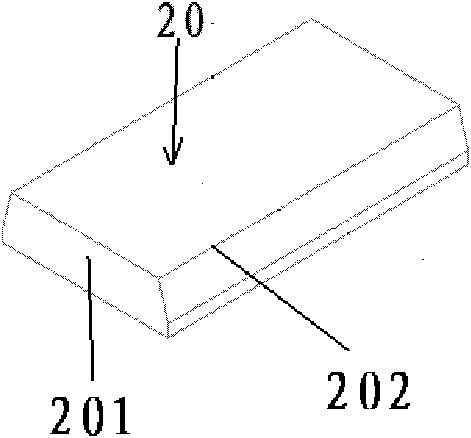

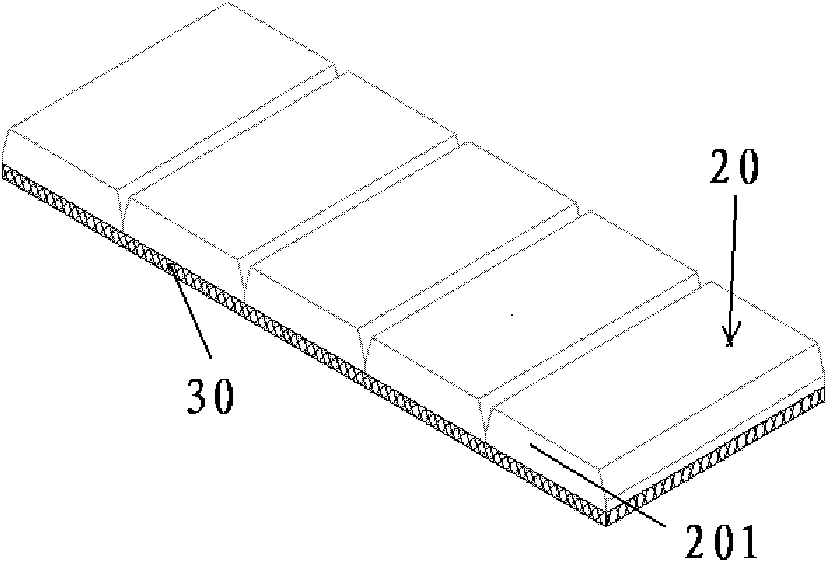

[0029] see Figure 1a , Figure 1a It is the steel wheel balance block 20 of the present invention. The steel wheel balance block 20 is made of ordinary carbon steel material, including a lower bottom surface that can be pasted with double-sided adhesive tape, and an upper surface parallel to the lower bottom surface. The bottom surface has a one-piece structure formed by integral stamping; both ends of the small steel wheel balance block 20 have uniform punching sections 201 without slump. That is, each edge 202 on the small steel wheel balance block connecting the punched sections 201 at both ends of the steel wheel balance block is perpendicular to the punched sections 201 at both ends of the steel wheel balance bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com