Clip hook type wheel balance block and its producing method

A balance block and hook type technology, which is applied in the direction of wheel counterweight, balance rotating body, etc., can solve the problems of high labor intensity, low production efficiency, serious process environmental pollution, etc., and achieve good manufacturability and installation firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

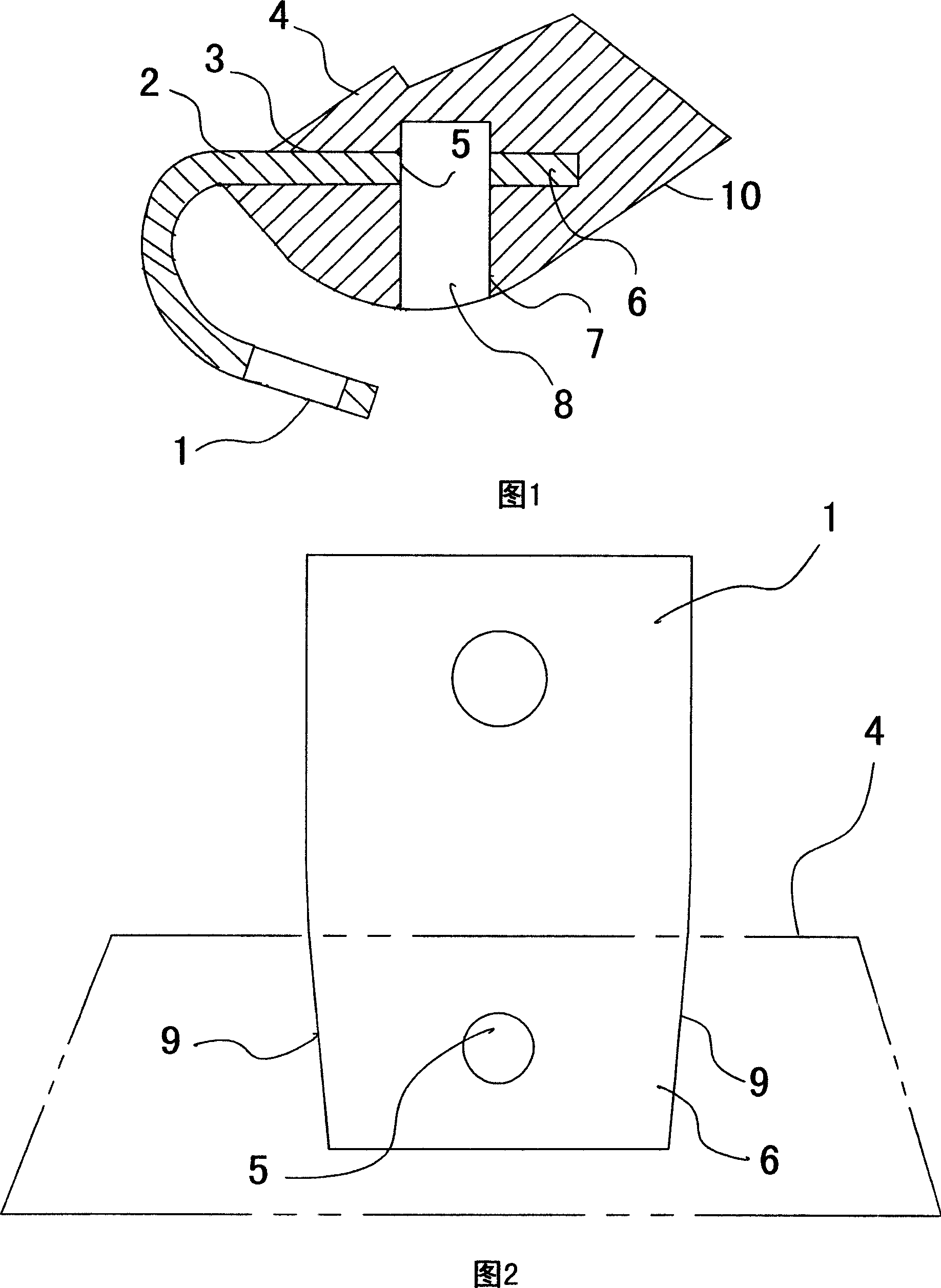

[0023] With reference to the accompanying drawings, the utility model includes a zinc alloy balance weight body 4 and a 65 manganese steel hook 2. Zinc alloys contain less than 0.1% lead. One end of the hook 2 is a curved fitting part 1 , and the other end is a joint part 6 fixed with the balance weight body 4 , and the hook joint part 6 has a riveting hole 5 . In order to better fix the joint points between the mounting groove 3 of the balance weight body 4 and the two sides of the hook joint part 6, the hook joint part 6 has a hypotenuse structure 9, and the two hypotenuses and the bottom edge of the hook joint part 6 form an inverted structure. Trapezoidal structure, when hook 2 is inserted in the mounting groove 3 of balance weight body like this, both can be stuck firmly. In the balance weight body 4, there are installation grooves 3 and rivet fixing h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com