Stable and reliable automobile balancing block and production process thereof

A technology of production process and balance weight, which is applied in the field of automobile balance weight and its production process, can solve the problems of high manufacturing cost of compressors, and achieve the effect of strong applicability, good product surface consistency and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

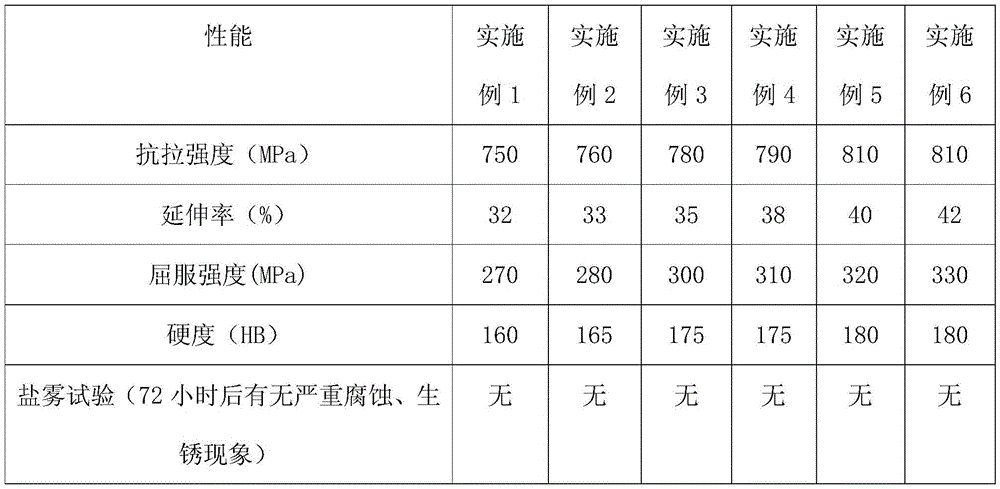

Examples

Embodiment 1

[0021] In an embodiment of the present invention, a stable and reliable automobile balance weight is made of the following elements, which include: 10% manganese, 0.05% thallium, 0.2% chromium, 0.5% silicon, 0.02% nickel, sulfur 0.08%, niobium 0.02%, carbon 0.5%, and the balance is iron and unavoidable impurities.

[0022] The production process of the stable and reliable automobile balance weight comprises the following steps:

[0023] 1) Place the crucible in a resistance furnace, raise the temperature to 380°C, and add iron.

[0024] 2) Raise the temperature of the resistance furnace to 1500°C, and remove the oxidized slag on the surface of the melt after all the iron is melted.

[0025] 3) Lower the resistance furnace to 1000°C, add preheated silicon, nickel, sulfur, and niobium, and keep warm for 40 minutes, stirring once every 10 minutes; then add preheated manganese, thallium, chromium, carbon, and keep warm for 20 minutes, Stir once every 10 minutes; remove scum.

...

Embodiment 2

[0029] In the embodiment of the present invention, a stable and reliable automobile balance weight is made of the following elements, which include: 30% manganese, 0.25% thallium, 1.5% chromium, 1.5% silicon, 0.8% nickel, sulfur 0.08%, niobium 0.15%, carbon 2.5%, and the balance is iron and unavoidable impurities.

[0030] The production process of the stable and reliable automobile balance weight comprises the following steps:

[0031] 1) Place the crucible in a resistance furnace, raise the temperature to 420°C, and add iron.

[0032] 2) Raise the temperature of the resistance furnace to 1650°C, and remove the oxidized slag on the surface of the melt after all the iron is melted.

[0033] 3) Lower the resistance furnace to 1250°C, add preheated silicon, nickel, sulfur, and niobium, and keep warm for 80 minutes, stirring once every 10 minutes; then add preheated manganese, thallium, chromium, carbon, and keep warm for 40 minutes, Stir once every 10 minutes; remove scum.

...

Embodiment 3

[0037] In the embodiment of the present invention, a stable and reliable automobile balance weight is made of the following elements, which include: 12% manganese, 0.10% thallium, 0.4% chromium, 0.7% silicon, 0.04% nickel, sulfur 0.040%, niobium 0.05%, carbon 0.7%, and the balance is iron and unavoidable impurities.

[0038] The production process of the stable and reliable automobile balance weight comprises the following steps:

[0039] 1) Place the crucible in a resistance furnace, raise the temperature to 390°C, and add iron.

[0040] 2) Raise the temperature of the resistance furnace to 1550°C, and remove the oxidized slag on the surface of the melt after all the iron is melted.

[0041] 3) Lower the resistance furnace to 1100°C, add preheated silicon, nickel, sulfur, and niobium, and keep warm for 40 minutes, stirring once every 10 minutes; then add preheated manganese, thallium, chromium, carbon, and keep warm for 20 minutes, Stir once every 10 minutes; remove scum. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com