Elastic wheel noise reduction damper and assembly installation method thereof

An elastic wheel and damper technology, applied in the direction of wheels, wheel counterweights, and wheels characterized by track walking components, can solve the problems of narrow noise reduction frequency band, general noise reduction effect, thin damping sheet thickness, etc. The effect of large structural damping and vibration absorption quality, improving noise reduction reliability and durability, and increasing the number of resonance frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

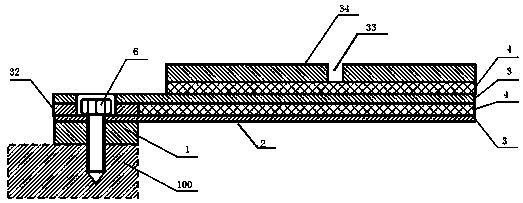

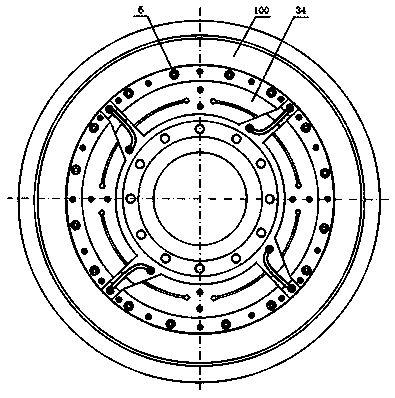

[0033] The elastic wheel noise reduction damper includes an annular transition plate 1 that is fixed to the side of the vehicle hoop and a damper body 2 that is rigidly connected to the annular transition plate 1 and is axially spaced from the side of the vehicle hoop. The device body 2 includes metal plates 3 stacked in sequence and a rubber damping layer 4 filled between the metal plates 3. The multi-layer metal plates 3 are fixed by rivets 5, and the annular transition plate 1 is also fixed by rivets 5. The riveting force of 5 does not act on the rubber damping layer 4.

[0034] As shown in the figure, in the elastic wheel noise reduction damper of the present invention, an annular transition plate 1 is spaced between the damper body 2 and the side surface of the wheel hoop 100 to form an integral resonance cantilever structure. The multi-layer metal plate 3 in the damper body 1 It is fixed by rivets 5, and the annular transition plate 1 is also fixed by rivets 5, and the r...

Embodiment 2

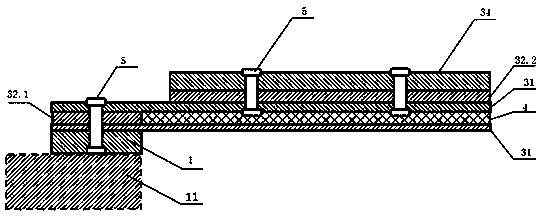

[0043] The difference from Embodiment 1 is that, as Image 6 As shown, the number of the rubber damping layer 4 is one layer, the connecting plate 32 is in the shape of a ring, and the two layers of the base plate 31 pass through the riveted mass block 7 . That is, there is no slit plate in the damper, only two layers of base plate, and a mass block 7 is added to greatly improve the vibration absorption quality of a certain order or a certain order of two frequencies. frequency for noise reduction.

[0044] The assembly and installation method of the elastic noise reduction damper described above includes the following steps:

[0045] 1. According to the main frequency of vibration noise and the axial modal frequency of each order of the tire when the elastic wheel is running, determine the natural frequency parameters of the elastic noise reduction damper to match the axial modal frequency of the tire;

[0046] 2. According to the natural frequency parameters of the elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com