Automatic adhesive-tape application machine for sticking car hub balance block

A technology of balancing weights and sticking tapes, which is applied in the direction of wheel counterweight, balancing rotating bodies, and sending objects, which can solve problems such as low production efficiency, walking errors, and unstable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

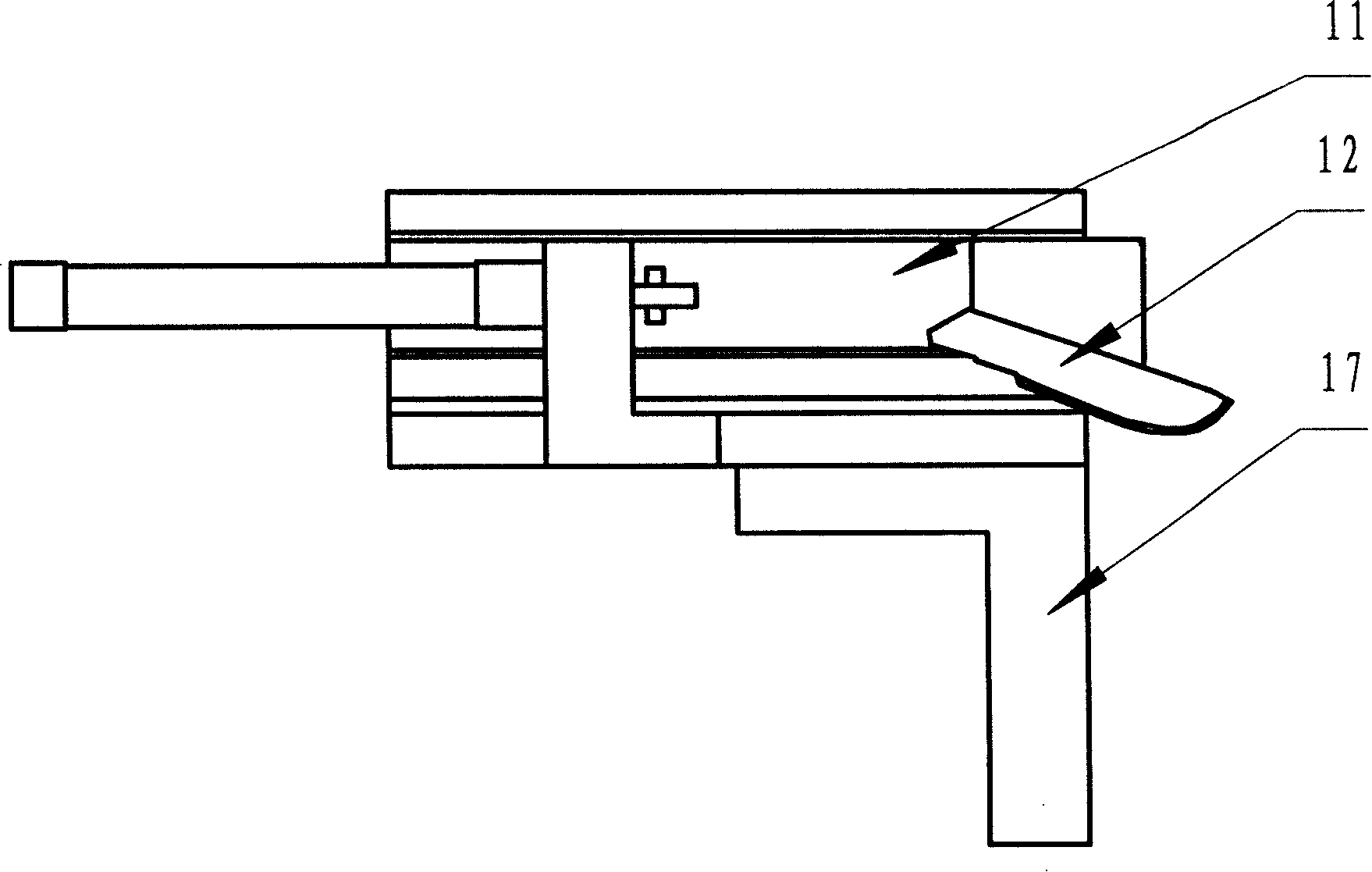

[0016] The blank of the balance weight in this embodiment adopts an arc shape, so the guide groove, the horizontal horizontal pushing plate, and the vertical horizontal pushing plate all adopt an arc-shaped structure.

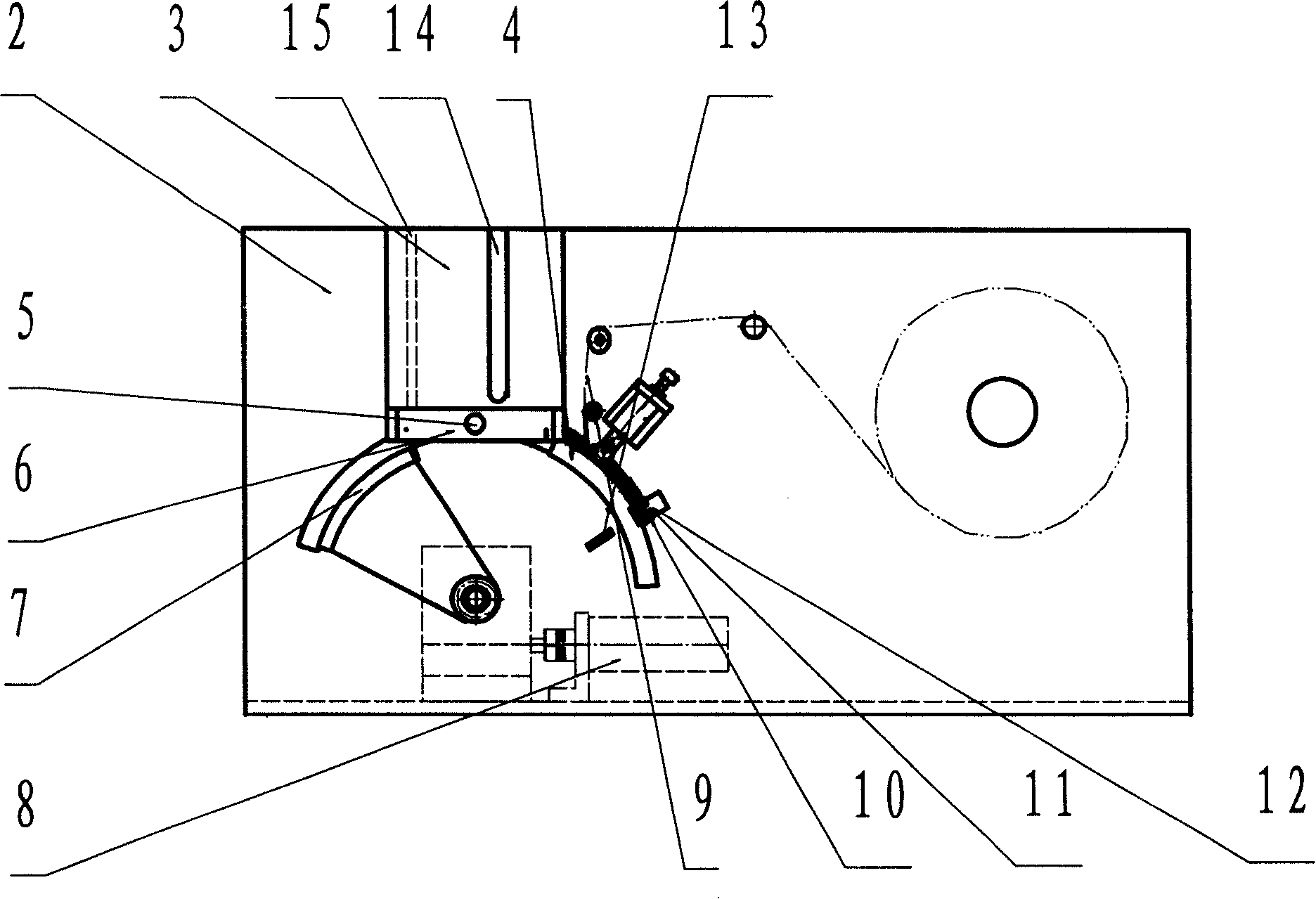

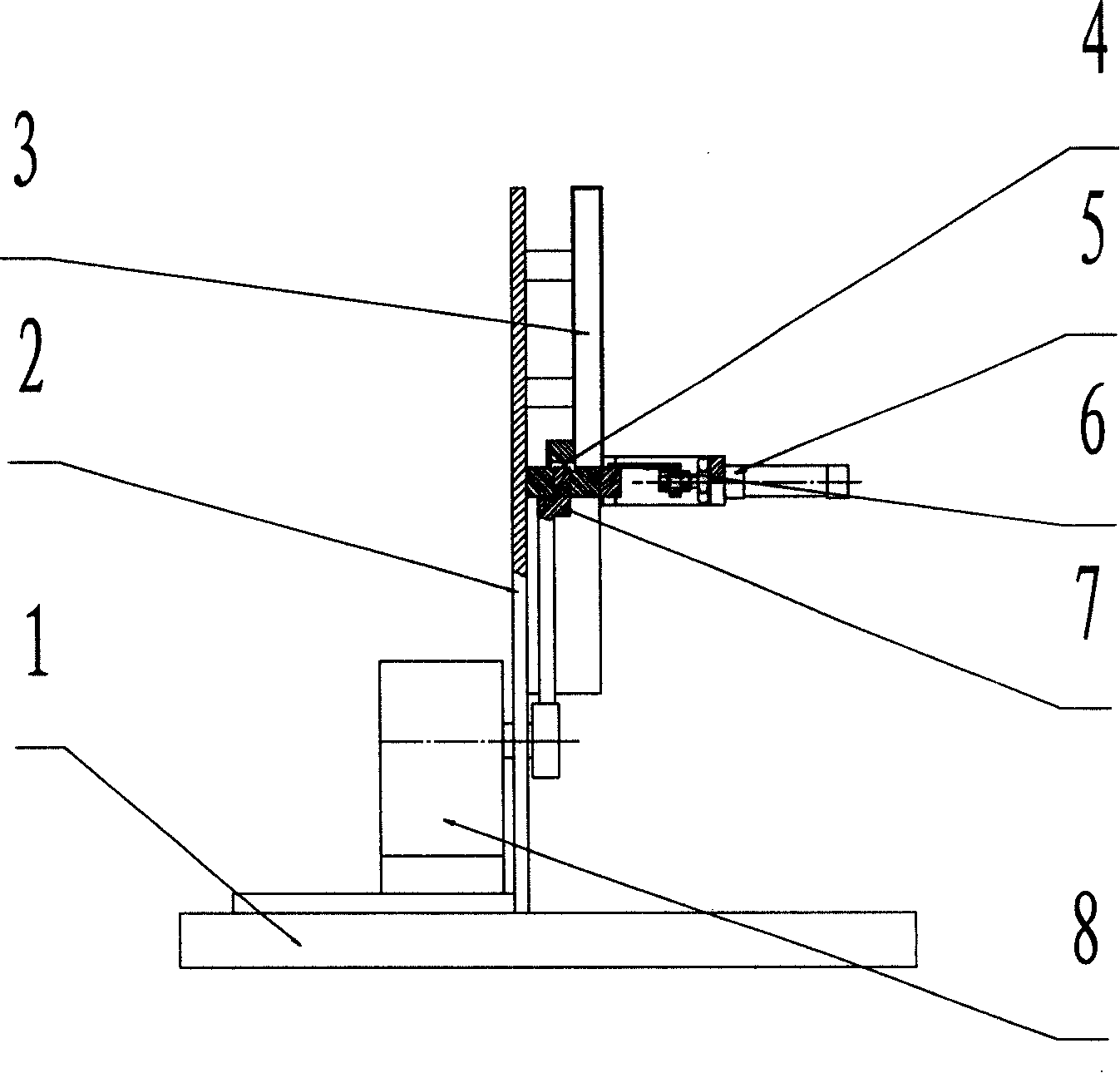

[0017] The automatic tape sticking machine for pasting the balance weight of the car wheel hub of the present invention comprises a box body 1 with a front side door, a built-in vertical plane shelf 2, and the vertical plane shelf is connected with a material bin 3 and a material guide. Groove 4, horizontal pneumatic pushing device, vertical pushing device, tape feeding and pressing device, tape cutting device and automatic control system.

[0018] The overall layout adopts a vertical planar working arrangement. The left part is for material block feeding and positioning cutting parts, and the right part is for adhesive tape introduction and feeding parts. The workpiece area is closed and constant temperature, and the front door is opened.

[0019] The silo ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com