Method for simulative generation of working condition curve of electric vehicle

A technology for electric vehicles and working conditions, applied in the direction of vehicle testing, measuring electricity, measuring electrical variables, etc., can solve problems such as time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

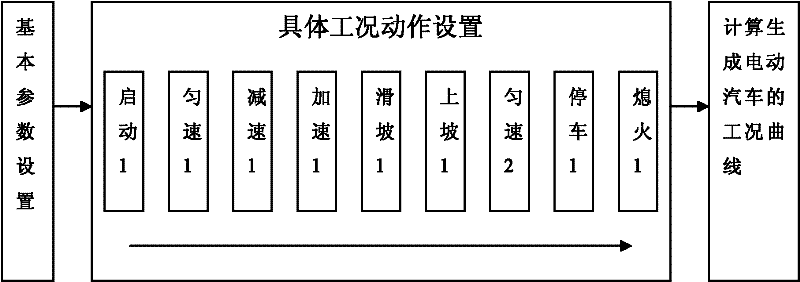

[0050] refer to Figure 5 , a method for simulating and generating electric vehicle operating condition curves, the flow chart of this embodiment is as follows figure 1 , including the following steps:

[0051](1) Set the basic information of the electric vehicle, including: vehicle shape (optional, divided into convertible car, box car body, foldback body, wedge-shaped body, K-shaped body, the best streamlined design), vehicle Type (optional, divided into sedan, canvas van, flatbed, van), vehicle curb weight, tire pattern (optional, divided into longitudinal, transverse, mixed, mud and snow, off-road, directional), tire width;

[0052] A specific example is as follows: vehicle curb weight: 1100kg, vehicle shape: streamlined design, electric vehicle type: sedan; tire pattern: longitudinal, tire width: 185mm.

[0053] Set the action type of the working condition, choose from start, constant speed, deceleration, acceleration, landslide, uphill, idle speed, stop or flameout;

...

Embodiment 2

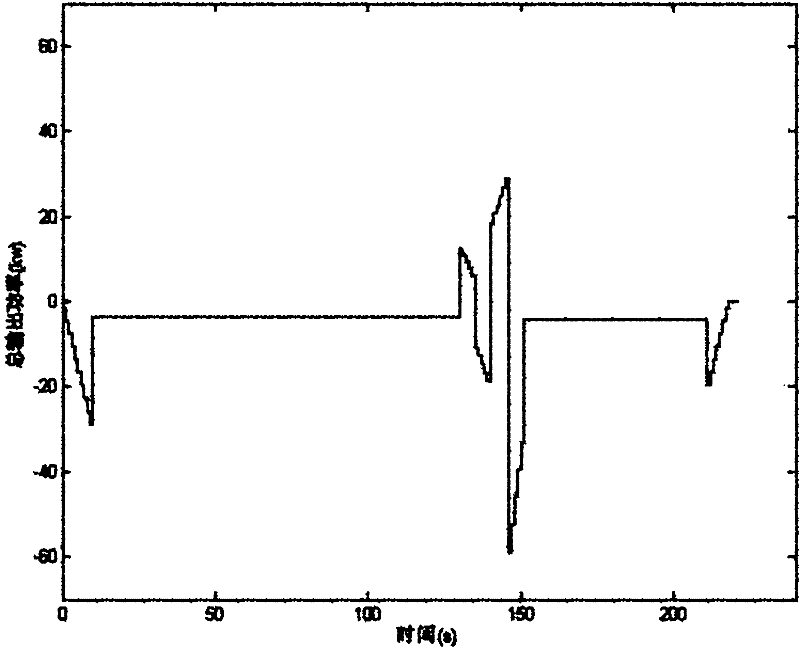

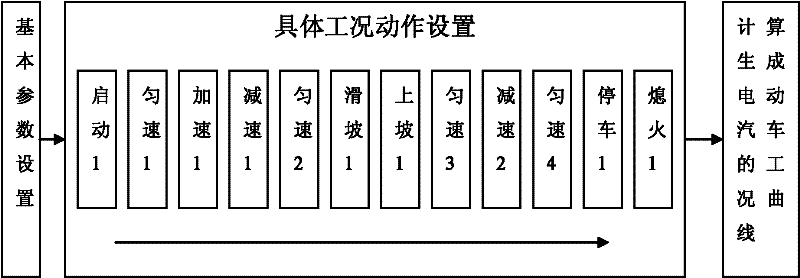

[0093] The flow chart of this embodiment is as image 3 , using the operating condition action type and parameters set in Table 9, other steps and parameters are the same as in Embodiment 1, and the corresponding electric vehicle operating condition curve can also be obtained, such as Figure 4 shown.

[0094] Table 9

[0095]

[0096]

[0097] To sum up, this patent is through the selection and setting of actions in various working conditions, and setting the execution order of each action, and finally simulates and generates the working condition simulation curve of the electric vehicle. Based on the generated working condition simulation curve, various This test is used to predict and analyze the dynamic performance of electric vehicle power batteries. This method has great flexibility and can simulate a variety of working conditions in reality, which greatly reduces the time and energy consumption of generating simulation curves of working conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com