Weight and Center of Gravity Adjustment Method of Locomotive Counterweight and Locomotives with Different Axle Load Conversion

A center of gravity adjustment and counterweight technology, applied in wheel counterweight, transportation and packaging, railway car body parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

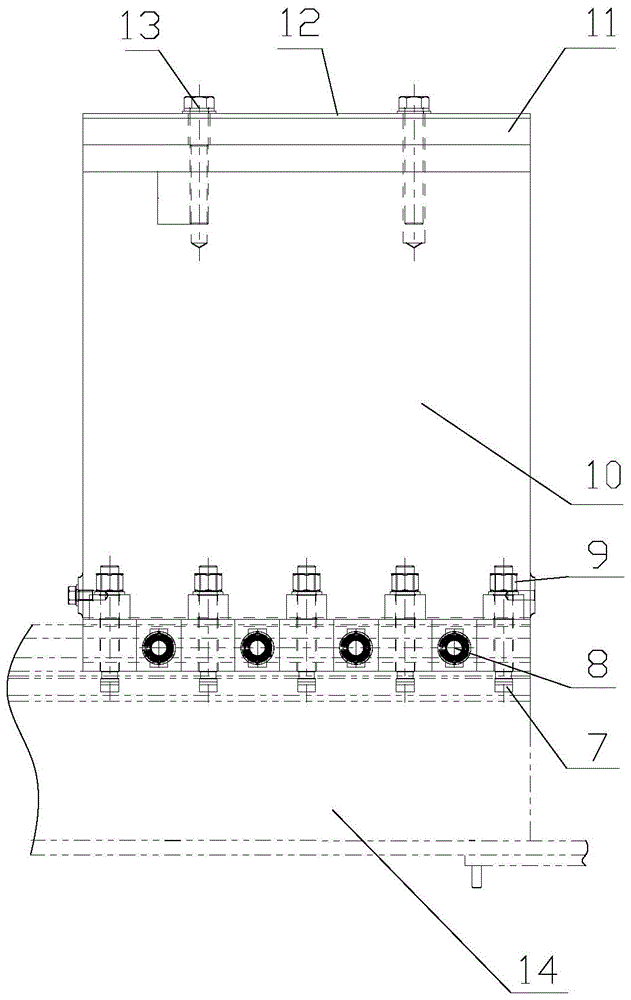

[0028] like figure 1 As shown, a locomotive counterweight includes a fixed counterweight 10, the lower part of the fixed counterweight 10 is connected with the machine room equipment mounting seat of the car body 14 through a connecting structure, and the upper part of the fixed counterweight 10 is provided with 2 An adjustable counterweight 11 with the same weight, a cover plate 12 is installed on the top of the adjustable counterweight 11, and the adjustable counterweight 11 and the cover plate 12 are installed on the fixed counterweight 10 with fasteners 13 through the same mounting holes. superior.

[0029] The weight of the fixed counterweight 10 accounts for 90% of the weight of the locomotive counterweight, and the weight of each adjusting counterweight 11 accounts for 5% of the weight of each counterweight of the locomotive.

[0030] The fastener 13 is a bolt, which is installed on the fixed counterweight 10 to adjust the counterweight 11 and the cover plate 12 . The...

Embodiment 2

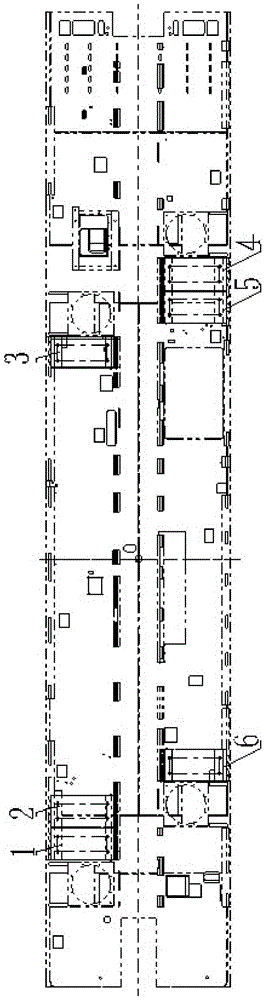

[0032] A method for adjusting the weight and center of gravity of locomotives with different axle load conversions. A certain 2 (B0-B0) axle locomotive needs to realize the conversion of 30-ton axle load and 27-ton axle load. When the axle load is 30 tons, the curb weight is (The curb weight of each locomotive ), curb weight at 27 tons axle load (The curb weight of each locomotive ). According to the state of axle load of 27 tons during design, the curb weight of each locomotive is 107.5 tons, and the total weight of counterweight is 12 tons, which becomes the state of axle load of 30 tons (the curb weight of each locomotive is 119.5 tons). The locomotive counterweight is divided into 6 pieces, adopting the locomotive counterweight in Embodiment 1, and the reference weight of each locomotive counterweight is 2 tons, wherein each counterweight is a fixed counterweight 10, The adjustment counterweight 11 that two single weights are 0.1 ton is formed.

[0033] The install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com