An opening and closing device for the main and auxiliary combustion chamber passage valves of a dimethyl ether engine

A technology for opening and closing devices and engines, which is applied in the direction of valve devices, engine components, machines/engines, etc., and can solve the problem that the valve timing and lift of the main and auxiliary combustion chamber channels of DME engines cannot be changed, which is unfavorable for DME engines. Optimize combustion, increase engine curb weight, etc., to achieve the effect of reducing curb weight, reducing curb weight, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

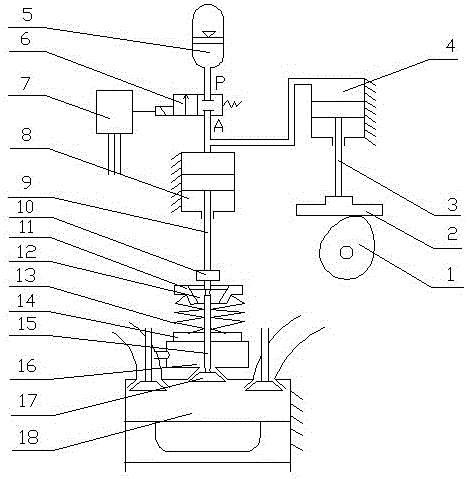

[0021] The utility model relates to an opening and closing device for passage valves of main and auxiliary combustion chambers of a dimethyl ether engine. The structure of the opening and closing device of the main and auxiliary combustion chamber channel valves of the dimethyl ether engine is as follows: figure 1 Shown:

[0022] The valve cam 1 is installed on the intake or exhaust camshaft, the lower plane of the first flat chassis 2 is in contact with the valve cam 1 through the high pair, and one end of the piston rod 3 of the first cylinder is the same as the upper plane of the first flat chassis 2 The center is fixedly connected, and the other end of the piston rod 3 of the first cylinder is fixedly connected with the piston of the first cylinder 4 coaxially. The rodless chamber of the first cylinder 4 communicates with the A port of the two-position two-way solenoid valve 6 and the rodless chamber of the second cylinder barrel 8 through a three-way pipe joint, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com