A method, system, and related device for loading bulk materials based on multiple feeding ports

A technology for bulk materials and material openings, which is applied in the fields of bulk material loading, computer readable storage media, and automatic loading devices, and can solve problems such as multiple loading or replacement, and unsatisfactory loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

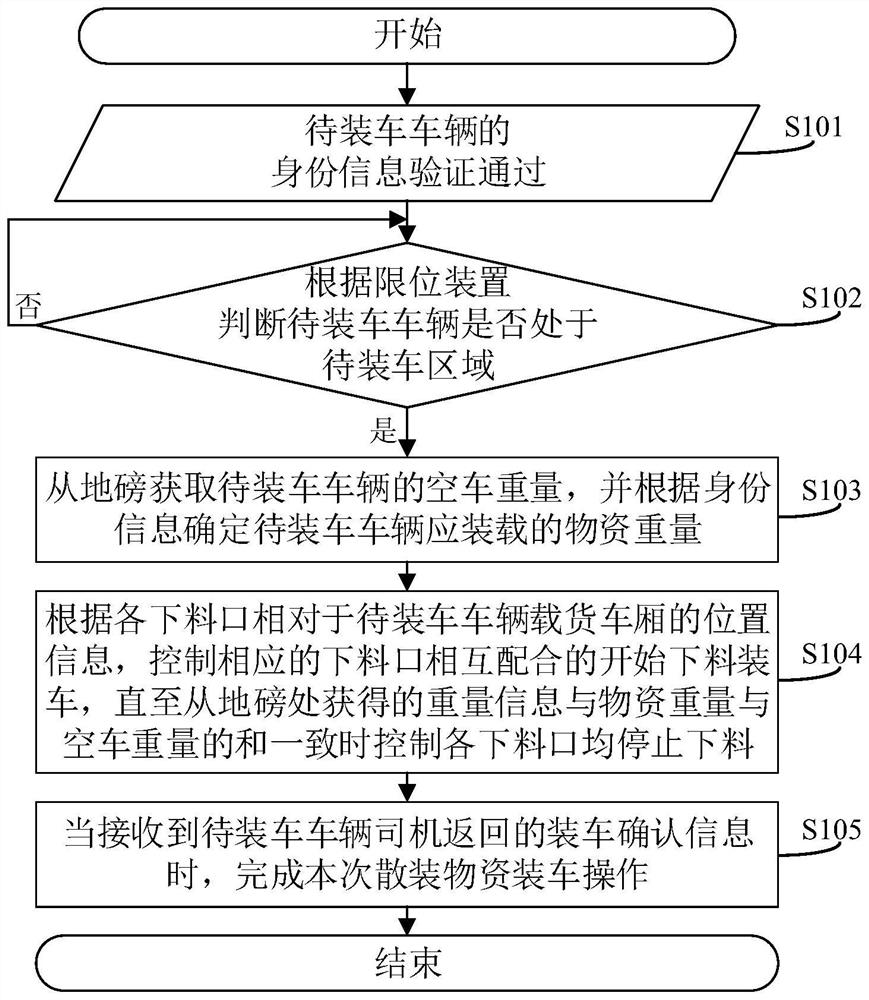

[0056] The following combination figure 1 , figure 1 A flow chart of a bulk material loading method based on multiple feeding ports provided in the embodiment of the present application, which specifically includes the following steps:

[0057] S101: Pass the verification of the identity information of the vehicle to be loaded;

[0058] This step aims to provide an environment for the subsequent steps, that is, the subsequent steps are all in the actual scene where the identity information of the vehicle to be loaded is verified, and the identity information is verified to mean that the vehicle to be loaded is a legal vehicle, satisfying the following The basic conditions of material loading.

[0059] It should be noted that the traditional method of verifying the identity information of the vehicle to be loaded is generally based on the loading receipt given by the driver to the staff, which may include the corresponding license plate number, model, driver's name, company, ...

Embodiment 2

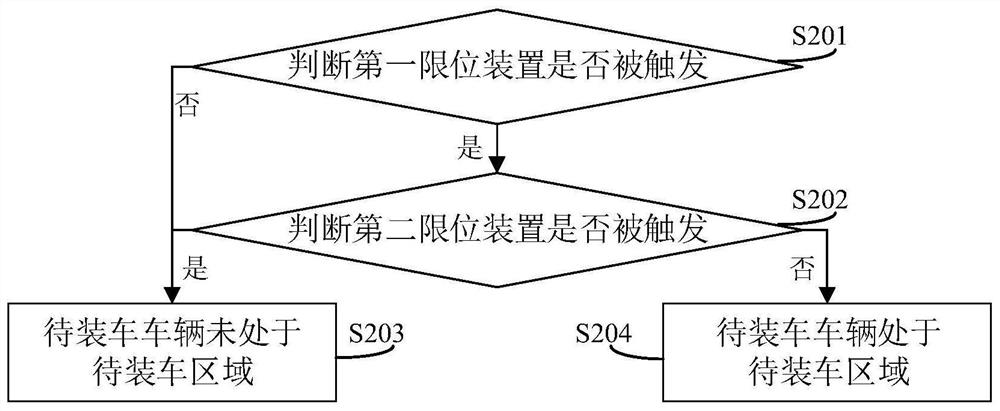

[0083] The following combination figure 2 , figure 2 The flow chart of a method for judging whether the vehicle to be loaded is in the area to be loaded based on the limit device in the bulk material loading method provided by the embodiment of the present application, the specific implementation steps are as follows:

[0084] S201: judging whether the first limit device is triggered;

[0085] The first limit device is set at the rear end of the weighbridge. The rear end is the end where the vehicle to be loaded enters the weighbridge first. It is used here to judge whether there is a vehicle entering the weighbridge. When the infrared signal sensing method is used, it will automatically The limit trigger signal is reported all the time when the front of the vehicle enters the rear end of the weighbridge until the rear of the vehicle fully enters the weighbridge.

[0086] S202: judging whether the second limit device is triggered;

[0087] This step is based on the judgme...

Embodiment 3

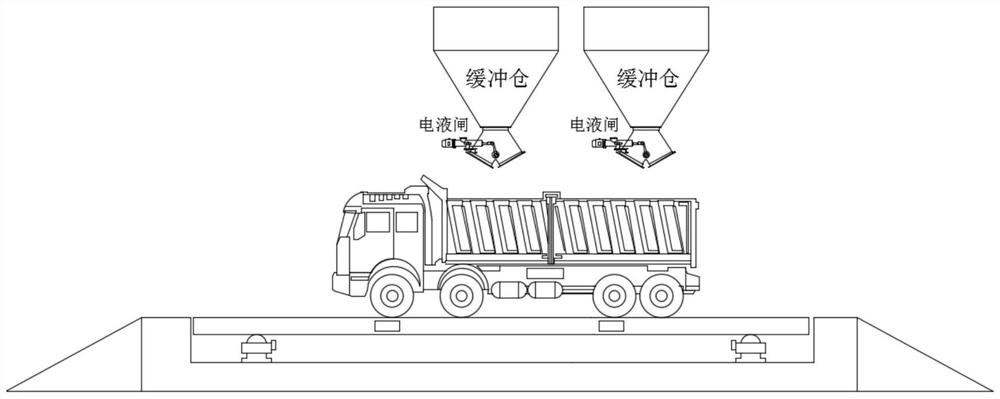

[0099] see below image 3 , image 3 A schematic structural diagram of a loading method with multiple feeding ports provided in the embodiment of the present application, as shown in image 3 As shown, there are two buffer warehouses, each buffer warehouse has a certain volume to store bulk materials, and each buffer warehouse has a discharge port, and these two discharge ports correspond to the stop at the weighbridge The front and rear two parts of the cargo compartment of the vehicle to be loaded on the vehicle, so under this model, there is no need to start and stop multiple times to change the parking position. image 3 In the position shown, open the discharge ports of the two buffer warehouses at the same time until the weight is consistent with the preset weight.

[0100] In the actual situation, when there are models with longer cargo compartments (for example, the length direction can accommodate 3 or more diameters of the bottom surface of the cone), and when ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com