Powder materials tanker and tank assembly thereof

A technology for transporting vehicles and materials, which is applied in the field of powder material transport vehicle tank body assembly and powder material transport vehicle, can solve the problems of small angle of fluidization plate, unsuitable for small angle, large angle change, poor fluidization effect, etc. Good for versatility, increased slippage speed, reduced residual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

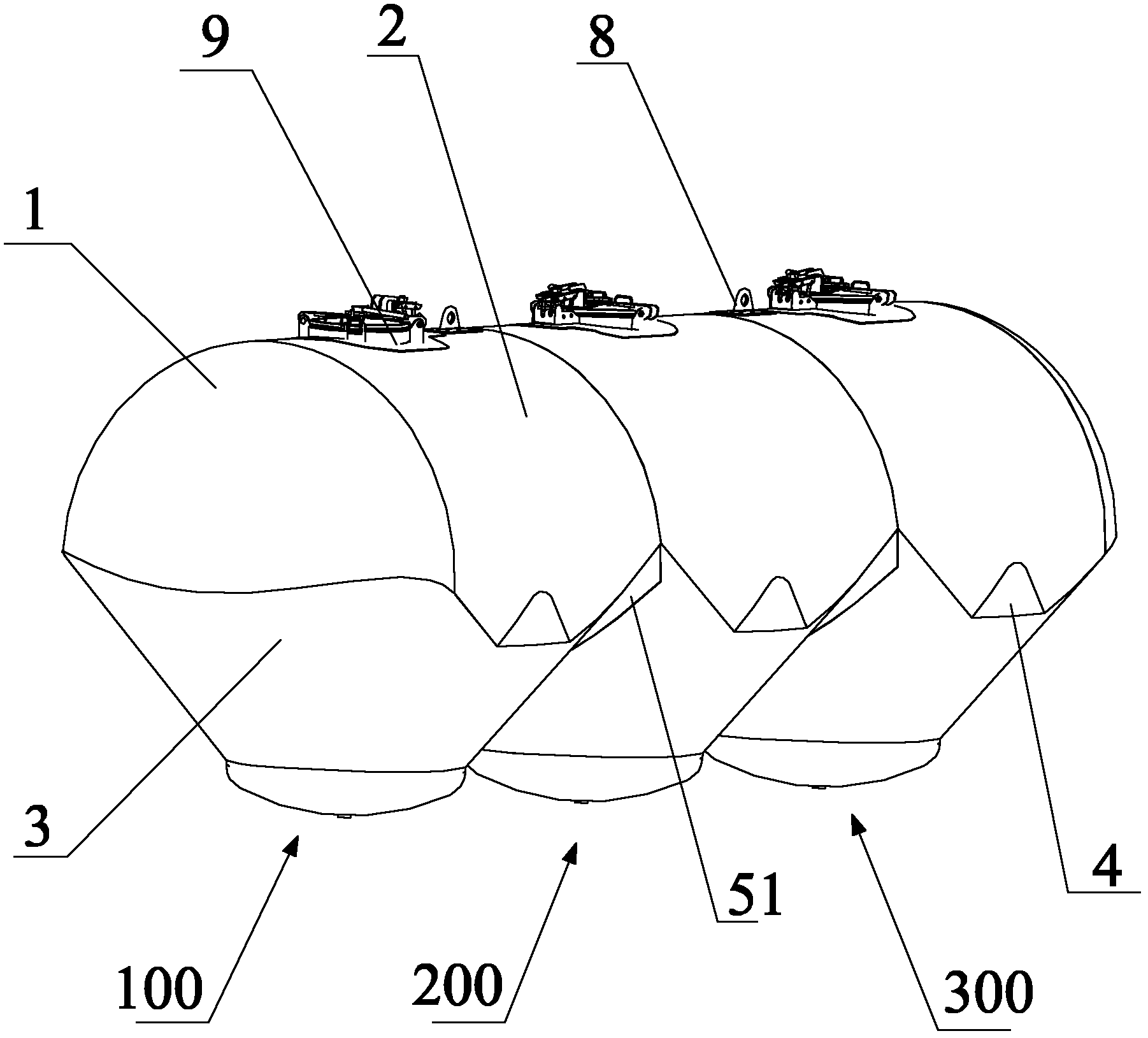

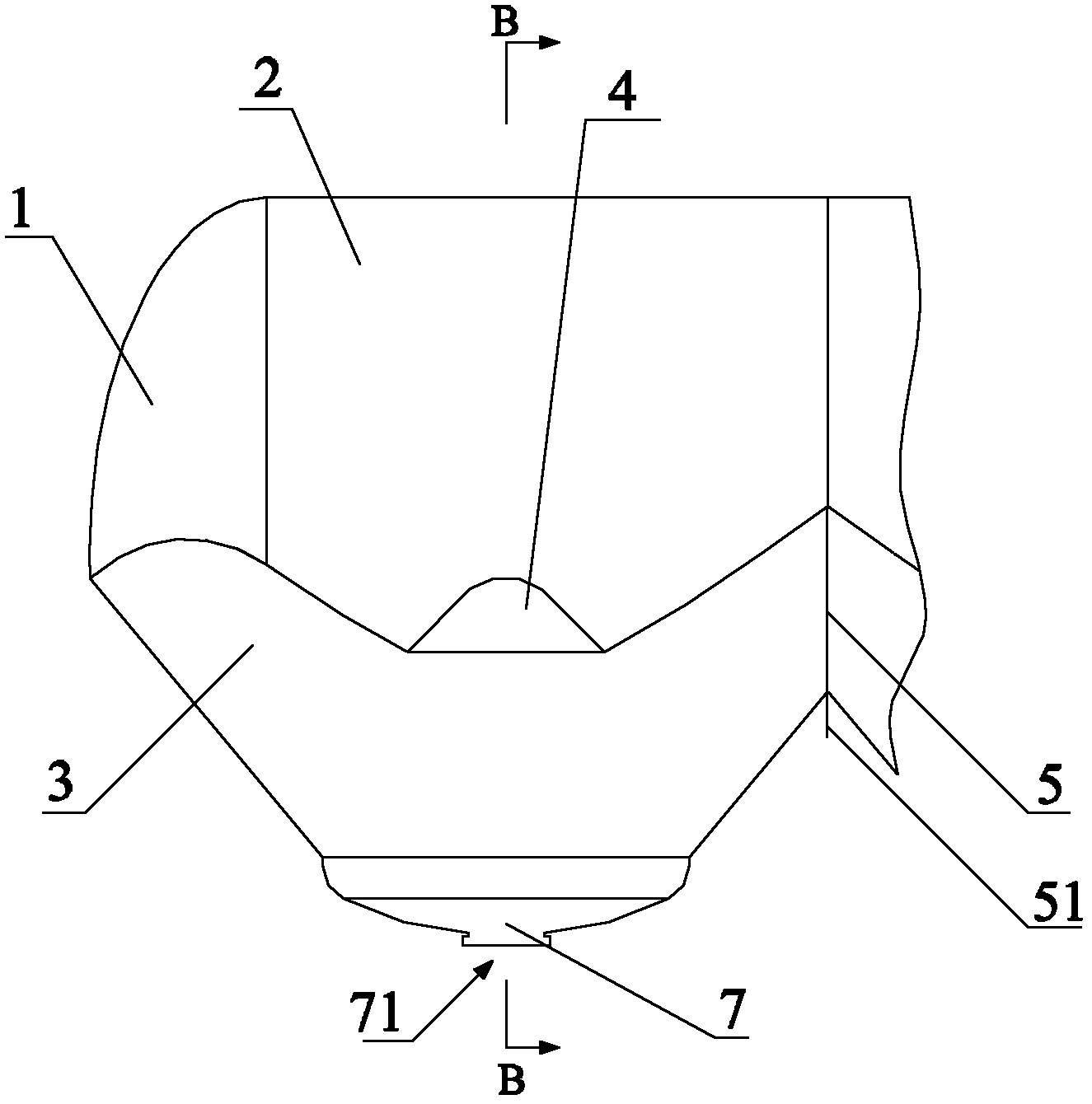

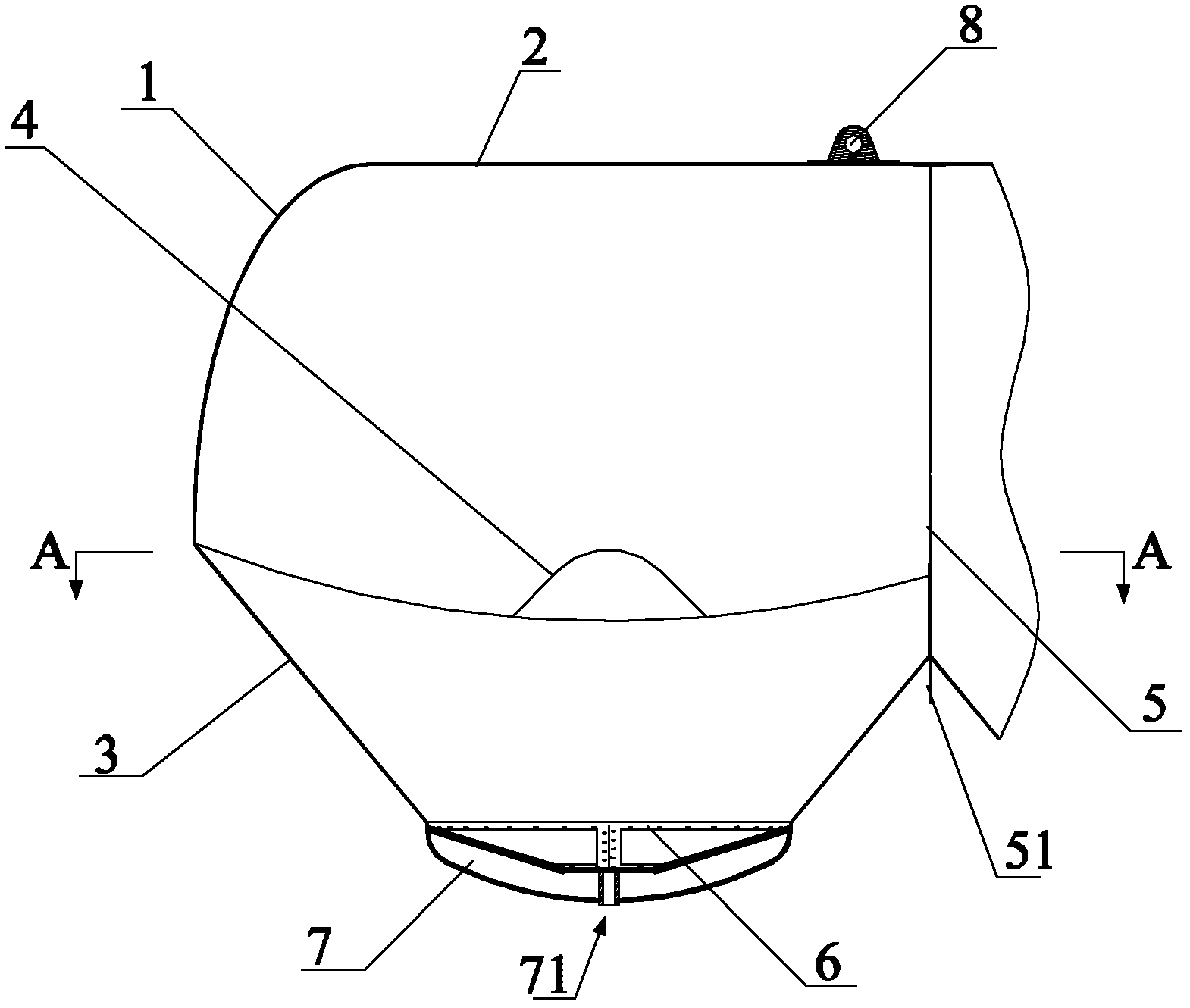

[0030] Figure 1 to Figure 5 A schematic structural view of a preferred embodiment of the tank body assembly of the powder material transport vehicle according to the present invention is shown. in, figure 1 It is a three-dimensional structural schematic diagram of an embodiment of the tank body assembly of the powder material transport vehicle according to the present invention, figure 2 yes figure 1 The schematic diagram of the front view of a warehouse body in the shown structure ( figure 2 The feed hole cover 9) is omitted in the image 3 yes figure 2 The schematic cross-sectional view of the structure shown, Figure 4 yes figure 2 Schematic diagram of the sectional view along A-A in the middle, Figure 5 yes figure 2 Schematic left view of the structure shown.

[0031] Such as Figure 1 to Figure 5 As shown, the present invention provides a tank body assembly for a powder material transport vehicle, which includes a bin body including a horizontal cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com