Light-weight semitrailer

A semi-trailer and lightweight technology, which is applied in the direction of tractor-trailer combination, motor vehicles, vehicle parts, etc., can solve the problems of semi-trailer curb weight, high transportation cost, waste of energy consumption, etc., to reduce material utilization, reduce Weight, promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

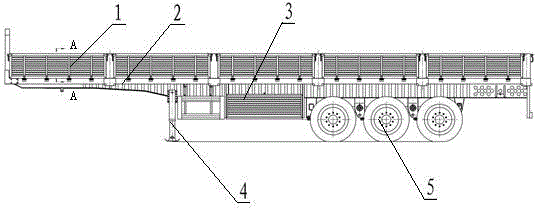

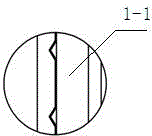

[0022] Example 1, see figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, according to the design requirements, all components are made of high-strength steel plates, and the upper wing plate 8 and the lower wing plate 10 are processed, and the width and thickness of the two are not equal A web 9 with a corrugated cross-section is made by bending, stamping or rolling, and the above-mentioned upper wing 8, lower wing 10 and web 9 are welded or riveted into an I-shaped frame longitudinal beam 6 , the web 9 uses corrugation to increase the strength of the frame longitudinal beam 6 in the vertical direction between the upper wing plate 8 and the lower wing plate 10; the vehicle frame assembly 2 is formed by two pieces of vehicle frame longitudinal beams 6 and related beams Lay the bottom plate 7 of the car frame on the frame assembly 2 to form the bottom plate assembly of the car frame to carry goods. Car box assembly 1 is installed on the base plate 7, so that loading goods is more con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com