Horizontal guiding drill while-drilling detection early warning system

An early warning system and detection system technology, applied in directional drilling, surveying, earthwork drilling and production, etc., can solve problems such as complex distribution of underground pipelines, hidden dangers of safe construction, and discounted detection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

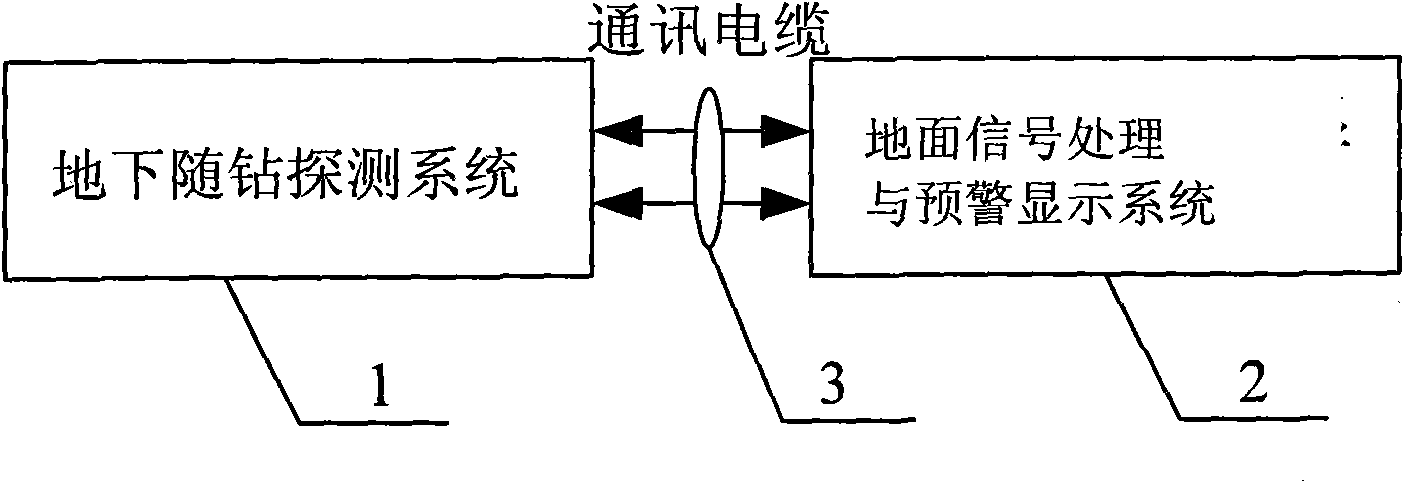

[0115] The following combination Figure 1 to Figure 12 , a preferred embodiment of the present invention is described in detail.

[0116] Such as figure 1 As shown, the present invention provides a detection-while-drilling and early-warning system for horizontal directional drilling, which includes: an underground detection-while-drilling system 1 and a ground signal processing and early warning display system 2, both of which are connected by a two-core communication cable 3 to realize high-speed data communication ;

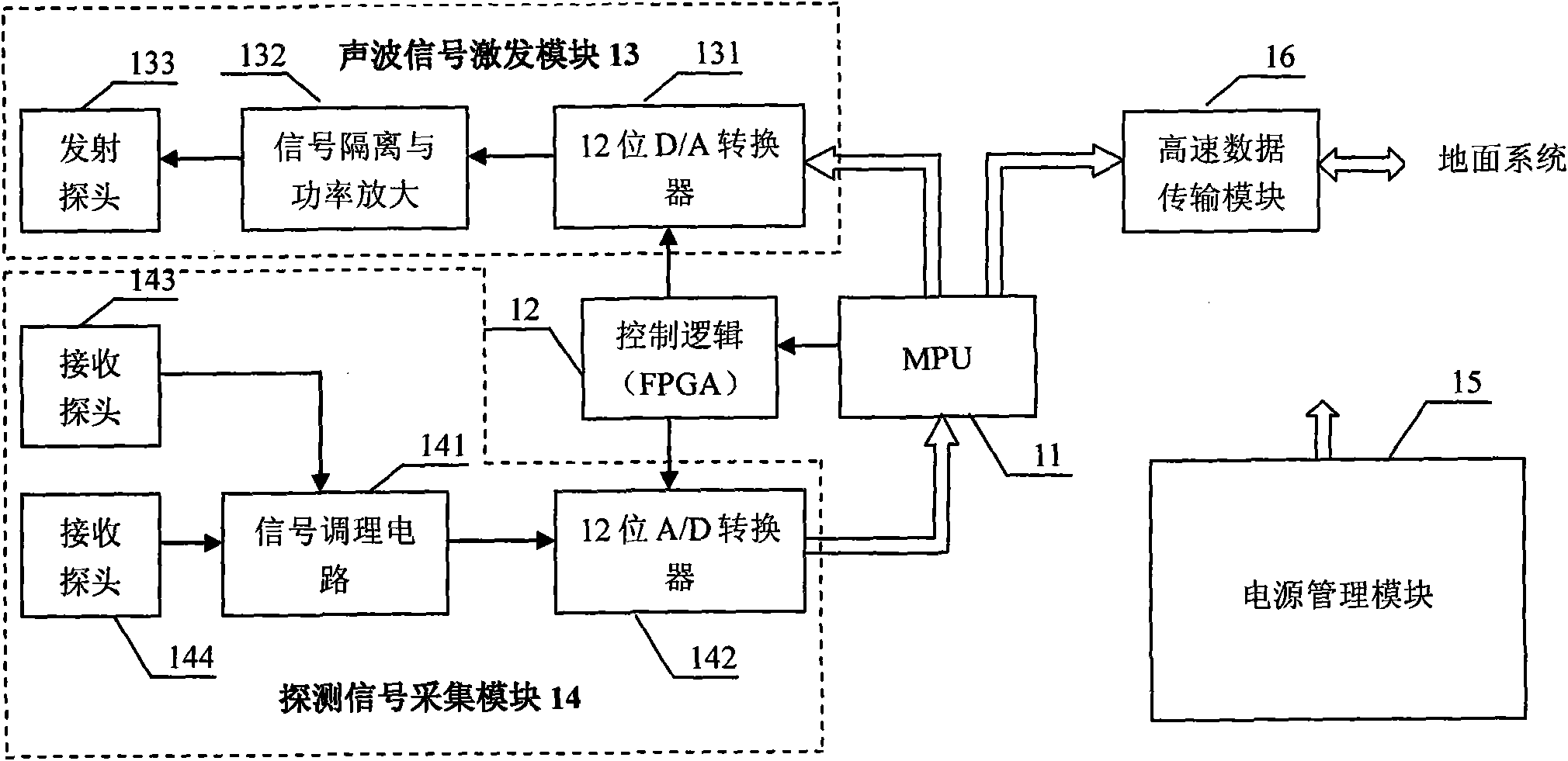

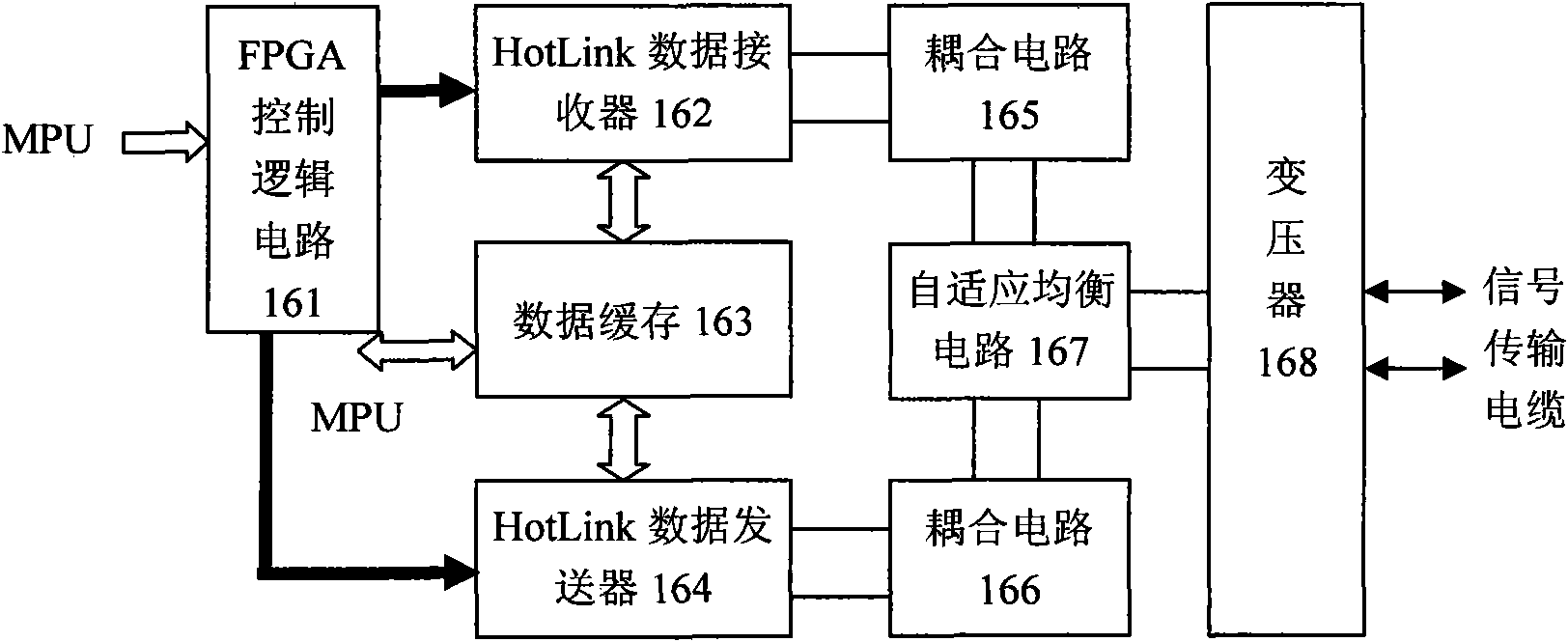

[0117] The underground detection-while-drilling system 1 works underground during the construction process, and uses active acoustic wave detection technology for detection to complete the data collection and transmission of underground pipeline detection; the ground signal processing and early warning display system 2 works on the ground, Complete the control of the underground detection while drilling system and the processing and display of detection data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com