Accurate positioning and detecting method and device for damages of underground metal pipeline anticorrosive coating

A metal pipeline, precise positioning technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problem of not being able to accurately obtain the damaged position, and achieve the effect of simple structure, high positioning accuracy and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

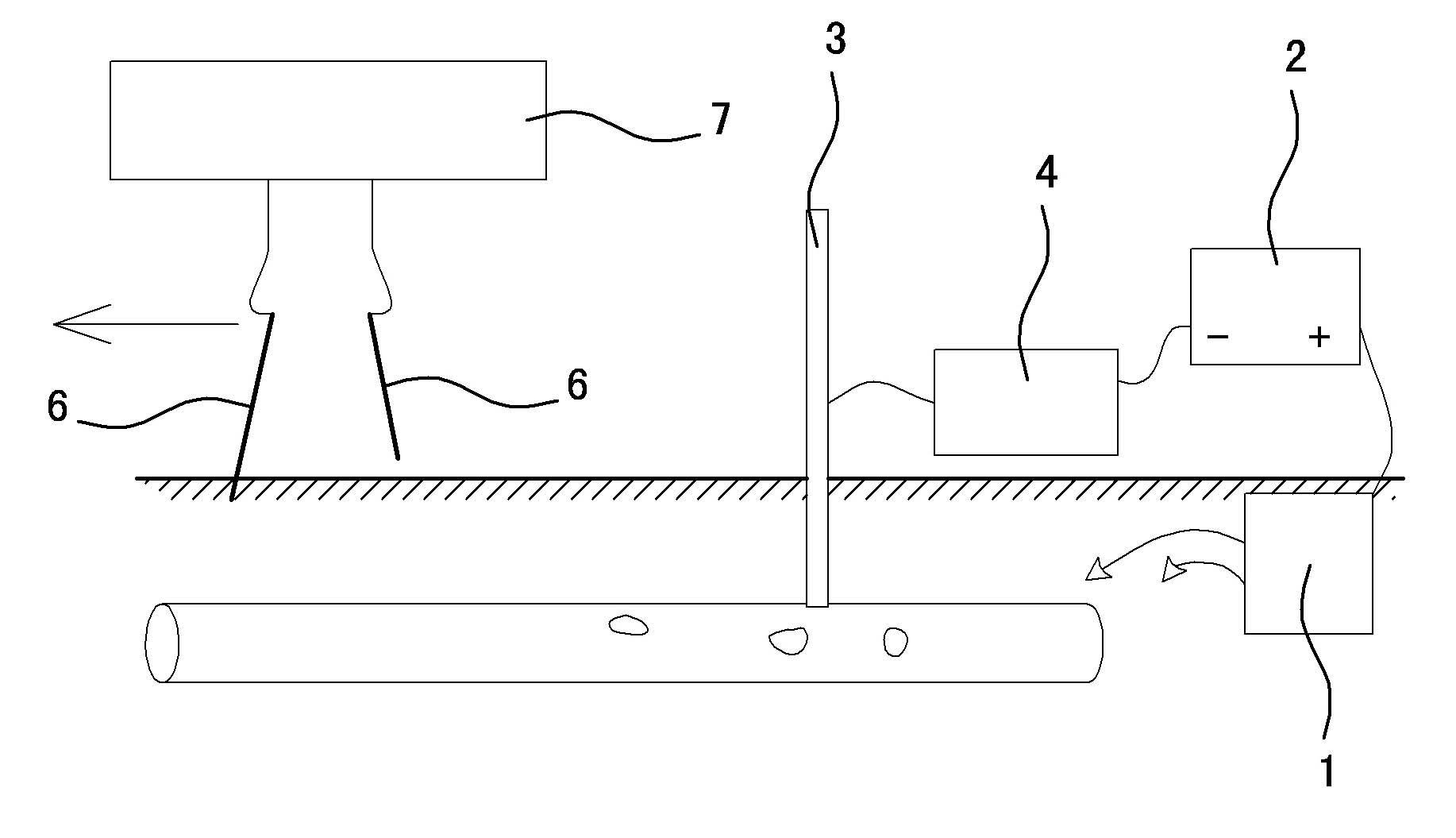

[0027] Embodiment one, such as figure 1 As shown, it includes an excitation signal device and a signal detection device. For a buried pipeline with a cathodic protection system, the excitation signal device is composed of a grounded anode 1, a cathodic protection rectifier 2, a buried pipeline test pile 3 and a current interrupter 4. The grounded anode 1, which is connected to the ground underground, is connected to the positive pole of the cathodic protection rectifier 2 through a wire, and inserted into the ground. The buried pipeline test pile 3 connected to the buried metal pipeline is connected to one end of the current interrupter 4 through a wire, and the current is interrupted. The other end of the device 4 is connected to the negative pole of the cathodic protection rectifier 2, and the buried pipeline test pile 3, the current interrupter 4, the cathodic protection rectifier 2 and the grounding anode 1 are connected in sequence to form an excitation signal circuit; th...

Embodiment 2

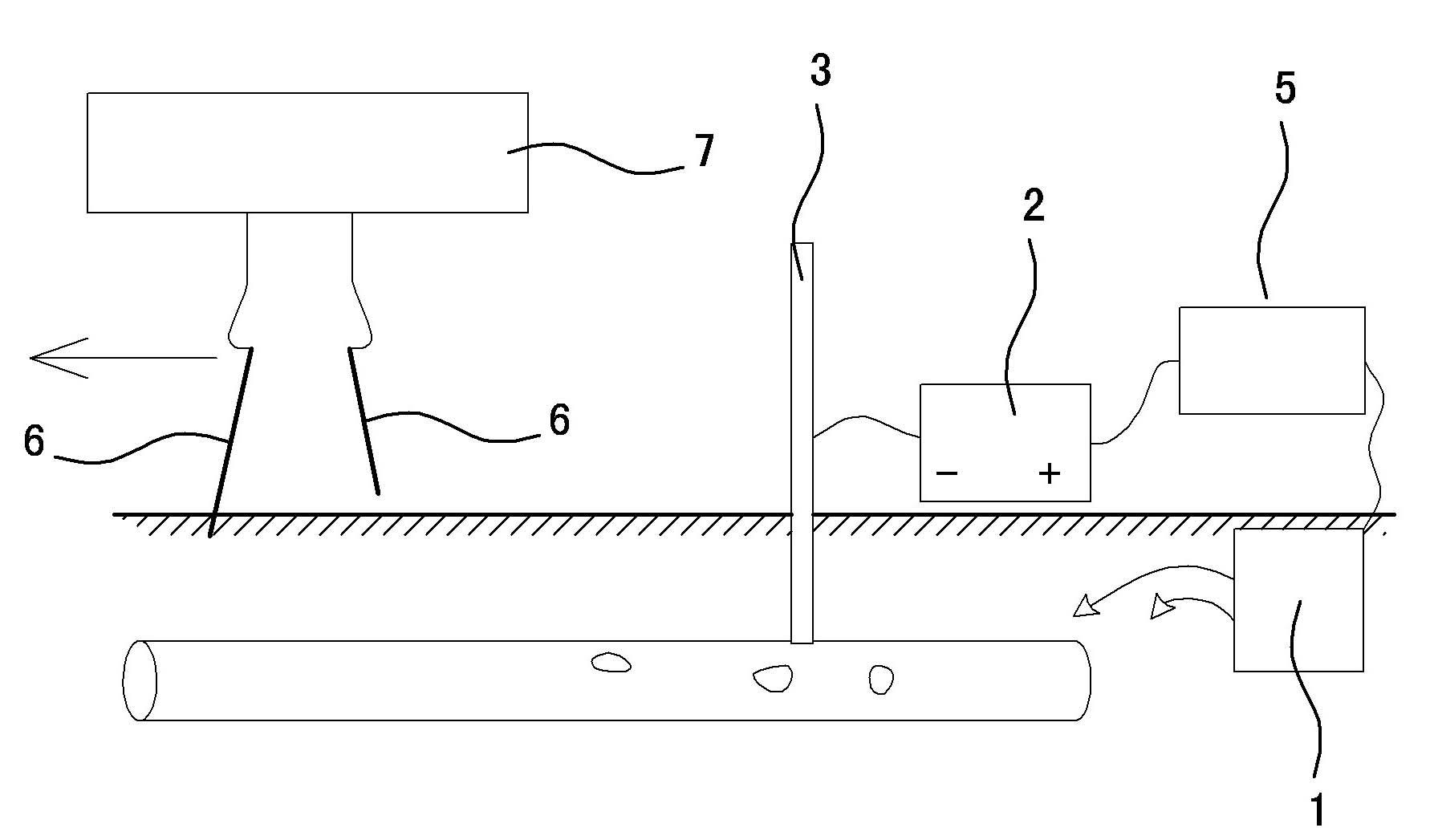

[0030] Embodiment two, such as figure 2 As shown, the difference from Embodiment 1 is that for a buried pipeline without a cathodic protection system, the excitation signal device is composed of a grounded anode 1, an external constant current source 5, a buried pipeline test pile 3 and a current interrupter 4. The positive pole of the external constant current source 5 is connected to one end of the current interrupter 4 through a wire, and the other end of the current interrupter 4 is connected to the grounding anode 1 buried underground and connected to the earth through a wire, and inserted into the ground to connect with the buried metal pipeline The buried pipeline test pile 3 is connected to the negative pole of the external constant current source 5 through wires, and the buried pipeline test pile 3, the external constant current source 5, the current interrupter 4 and the grounding anode 1 are connected in sequence to form an excitation signal circuit.

[0031] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com