Underground pipeline leak-detection method and apparatus

A leak detection device and technology for underground pipelines, which are applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of poor weak signal detection capability, expensive equipment, and expensive imported equipment, and improve reliability. The effect of reducing leak detection work intensity and improving leak detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

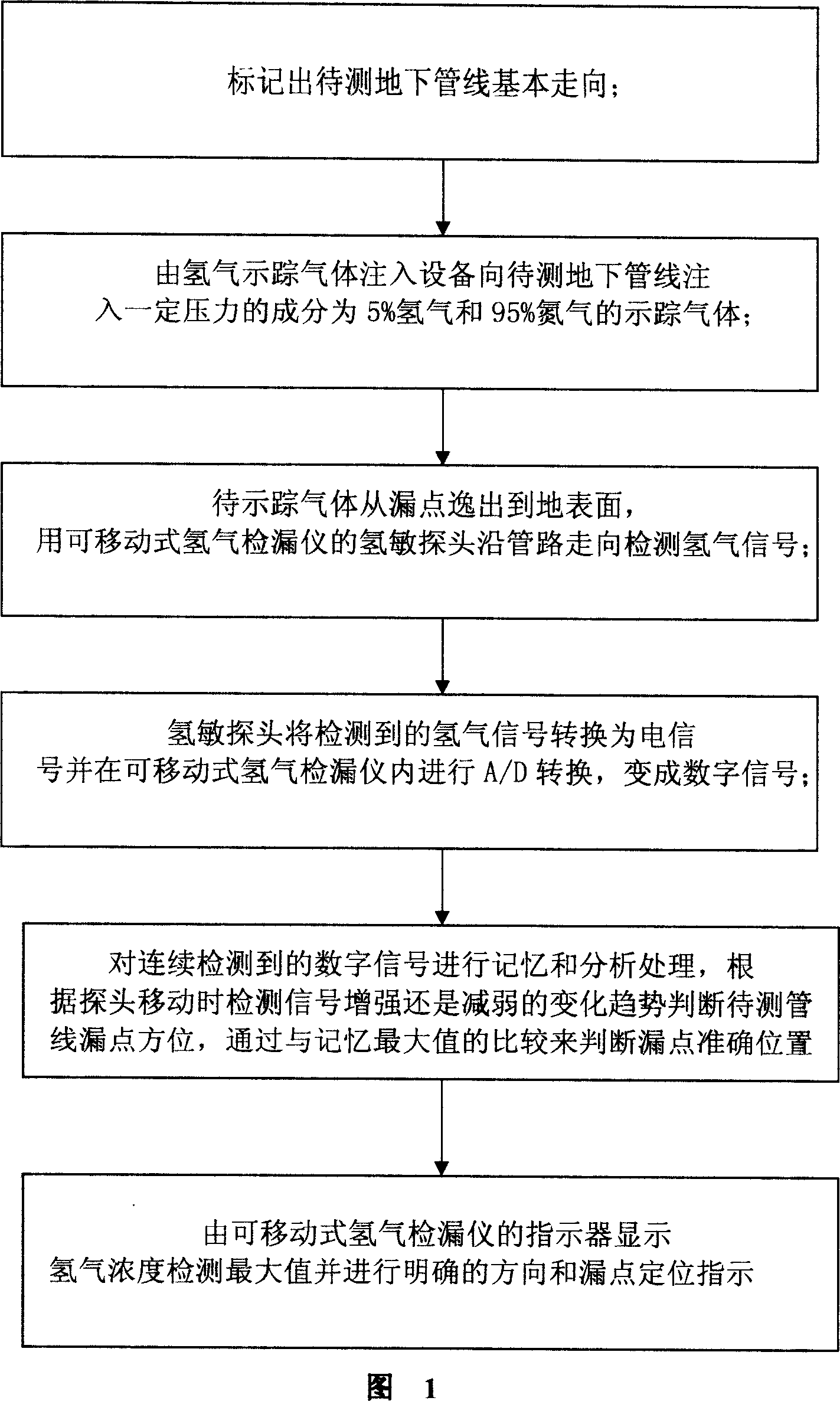

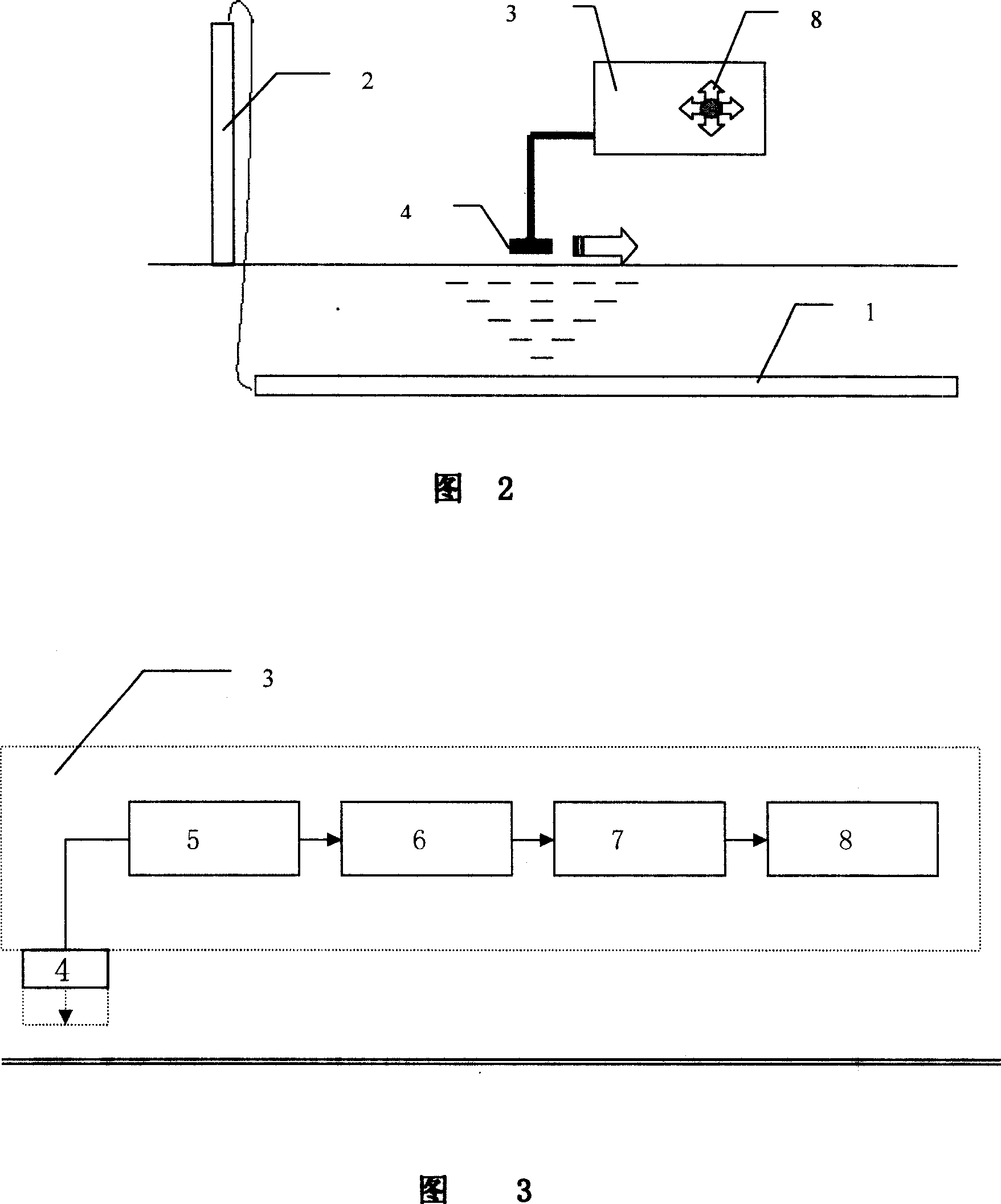

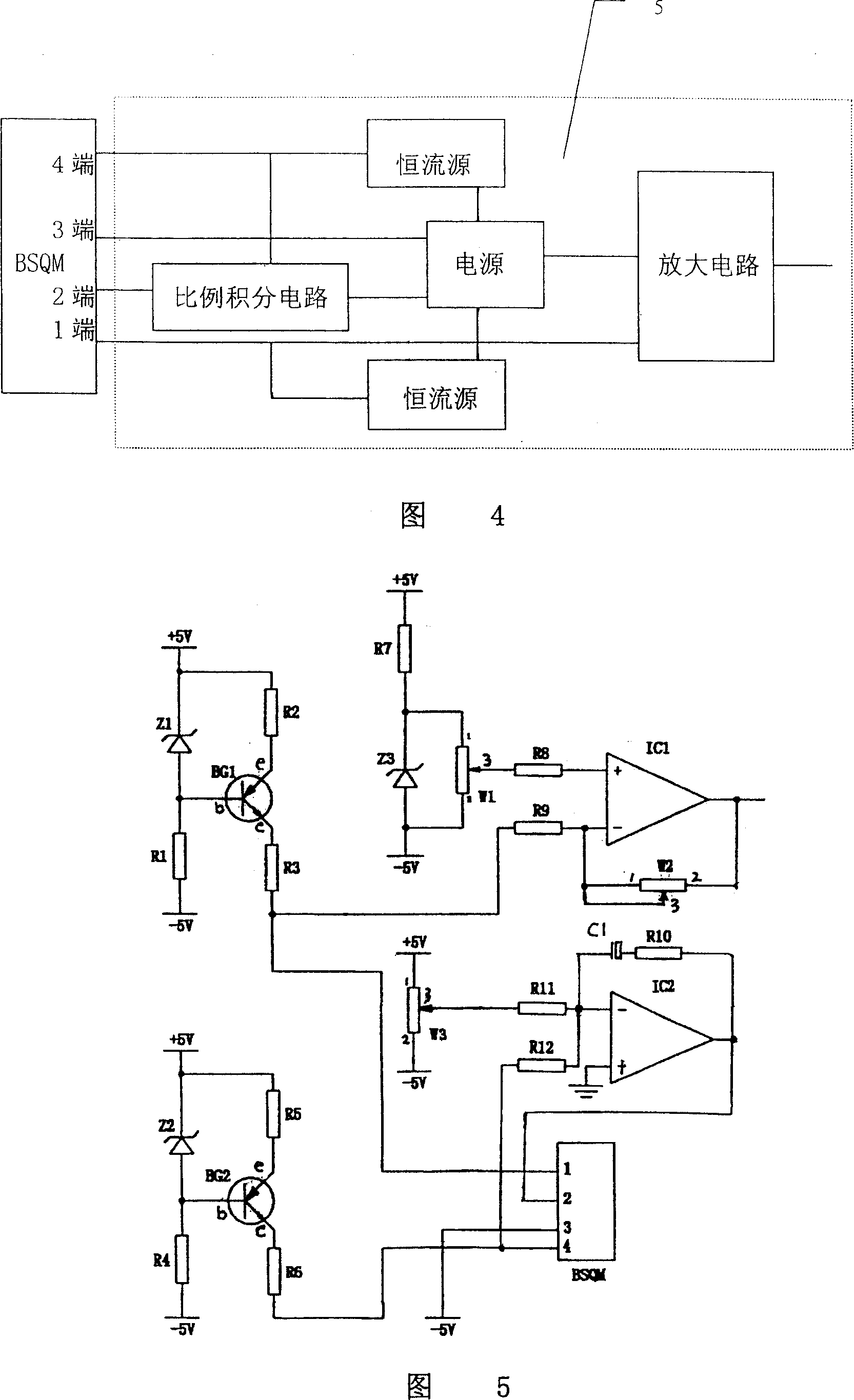

[0035] In Fig. 1, the underground pipeline leakage detection method provided by the present invention comprises underground pipeline, hydrogen tracer gas injection equipment and movable hydrogen leak detector, and its specific method is:

[0036] Mark the basic direction of the underground pipeline to be tested;

[0037] The hydrogen tracer gas injection equipment injects tracer gas with a certain pressure composition of 5% hydrogen and 95% nitrogen into the underground pipeline to be tested;

[0038] When the tracer gas escapes from the leak point to the ground surface, use the hydrogen sensitive probe of the portable hydrogen leak detector to detect the hydrogen signal along the pipeline;

[0039] The hydrogen sensitive probe converts the detected hydrogen signal into an electrical signal and performs A / D conversion in the portable hydrogen leak detector to become a digital signal;

[0040] Carry out memory storage, analysis and processing of the continuously detected digit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com