Vinyl monomer-polyvinyl cross-linking agent copolymer nonporous microsphere as well as preparation method and application thereof

A technology of vinyl monomers and polyvinyls, which is applied in chemical instruments and methods, other chemical processes, material separation, etc., can solve the problems of limited application, poor ion exchange performance, and affecting the service life of chromatographic packing, and achieve the elimination of non-specific Heterotropic adsorption, good mechanical stability, and remarkable separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0105] The present invention also provides a method for preparing non-porous microspheres of vinyl monomer-polyvinyl crosslinking agent copolymer, comprising the following steps:

[0106] Preparing vinyl monomer-polyvinyl crosslinking agent copolymer cue balls, the vinyl monomer-polyvinyl crosslinking agent copolymer cue balls are modified with hydroxyl groups;

[0107] The epoxy compound is grafted onto the vinyl monomer-polyvinyl crosslinking agent copolymer cue ball through hydroxyl reaction, and the epoxy compound contains at least two epoxy groups.

[0108] Further, the method for preparing vinyl monomer-multi-vinyl crosslinking agent copolymer cue ball comprises the steps:

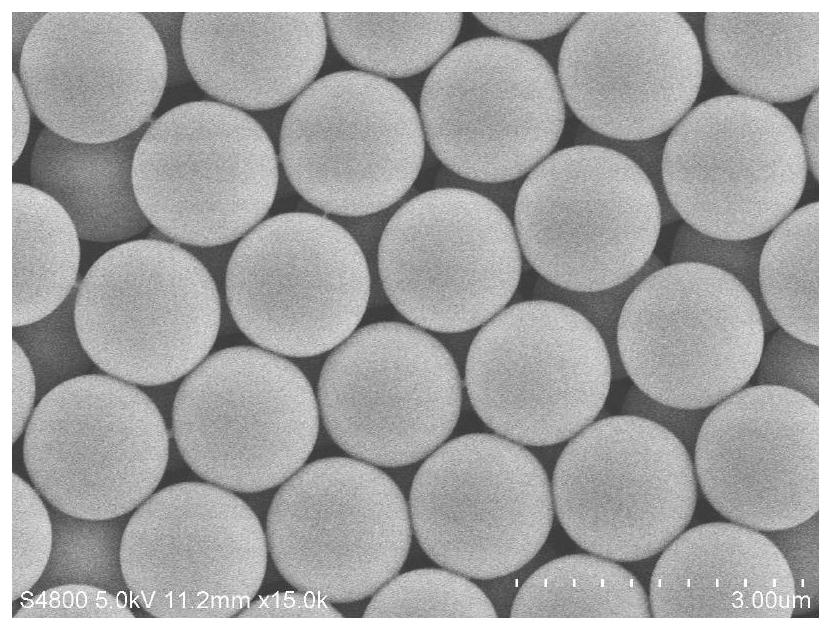

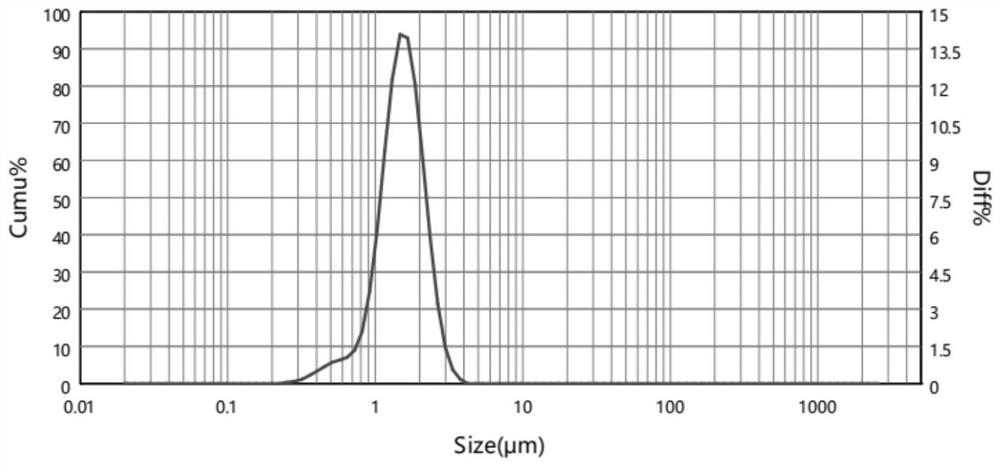

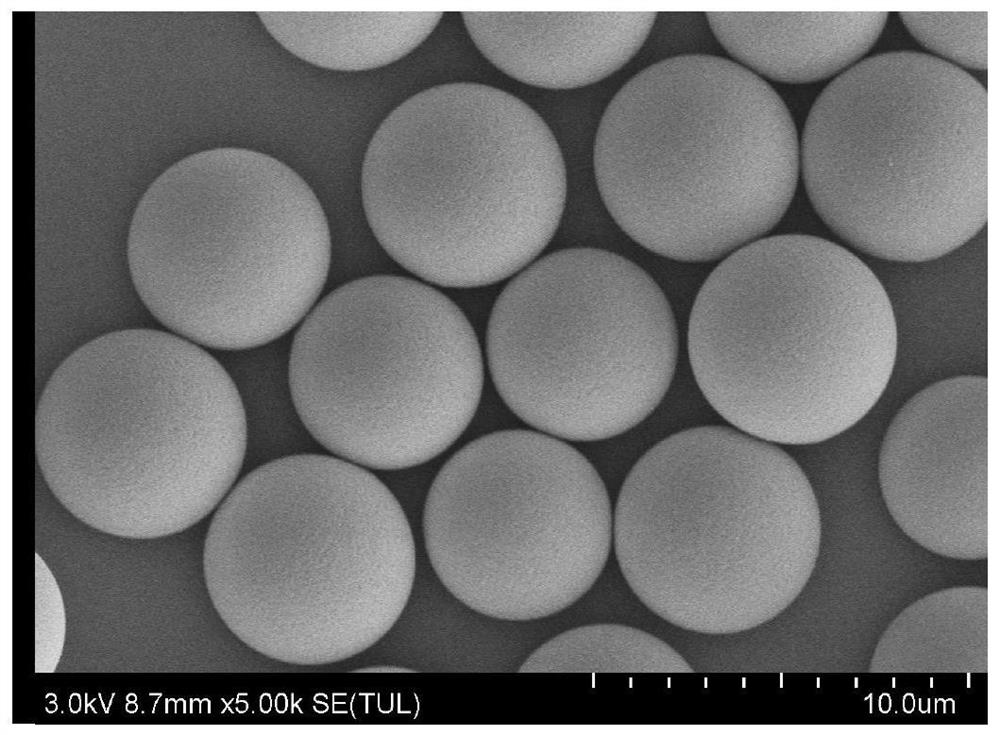

[0109] Prepare vinyl monomer-polyvinyl crosslinking agent copolymer particles, the vinyl monomer-polyvinyl crosslinking agent copolymer particles are modified with epoxy groups, the preparation steps include: using polystyrene seed microspheres as seeds , together with vinyl monomers and polyvinyl c...

Embodiment 14

[0178] The synthesis of embodiment 1 4-vinylphenyl glycidyl ether

[0179] In a 250mL three-necked flask, add 4-hydroxystyrene (7.22g, 60.1mmol) and ethanol (about 10mL) and stir to dissolve for later use; further add absolute ethanol (50mL) to a 100mL beaker equipped with a magnetic stirring bar and Dissolve NaOH (3.12 g, 78.0 mmol, 1.3 times the molar ratio) and stir for 30 minutes, then add to the above-mentioned three-necked flask. Epichlorohydrin (14.1 mL, 180 mmol, 3 times 1.3 times molar ratio) was then quickly added to the three-necked flask using a dropping funnel. Stirring at 150 rpm at room temperature, the reaction solution gradually became turbid, and sodium chloride slowly precipitated out. After continuing the reaction for 16 hours, 100 mL of water was added and stirred to dissolve the precipitated sodium chloride, and the mixture was extracted with hexane (2×100 mL) using a separatory funnel. Combine the organic phases with anhydrous MgSO 4 The oil phase was...

Embodiment 24

[0181] The synthesis of embodiment 2 4-vinylbenzyl glycidyl ether

[0182] A 500mL three-necked flask was fed with argon, and under an argon atmosphere, sodium hydride (60% in mineral oil, 13.1g, 327.60mmol, 2.00 times molar ratio) was added in DMF (300mL), and added dropwise at 0°C Glycidol (27.15 mL, 459.1 mmol, 2.50 times molar ratio). After the reaction mixture was stirred for 30 minutes, the stirring speed was controlled at 150 rpm, and 1-(chloromethyl)-4-vinylbenzene (23.3 mL, 163.80 mmol, 1.00 times molar ratio) was added dropwise, and stirring was continued at room temperature after the addition was completed React for 4 hours. The mixture was extracted with ethyl acetate (400 mL). Add saturated NH 4 Aqueous Cl solution (200 mL) was used to quench the reaction, and the aqueous layer was further extracted with ethyl acetate (3×100 mL). The combined organic layers were washed with anhydrous Na 2 SO 4 Dry the oil phase and remove the solvent under vacuum by rotary e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com