Construction method for laying water pipes

A construction method and technology of water pipelines, which are applied in the main water supply pipeline, water supply pipeline system, sewer pipeline system, etc., can solve the problems of large maintenance and repair costs, weak corrosion resistance, low construction efficiency, etc., and achieve maintenance and repair Simple and easy to operate, good corrosion resistance, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

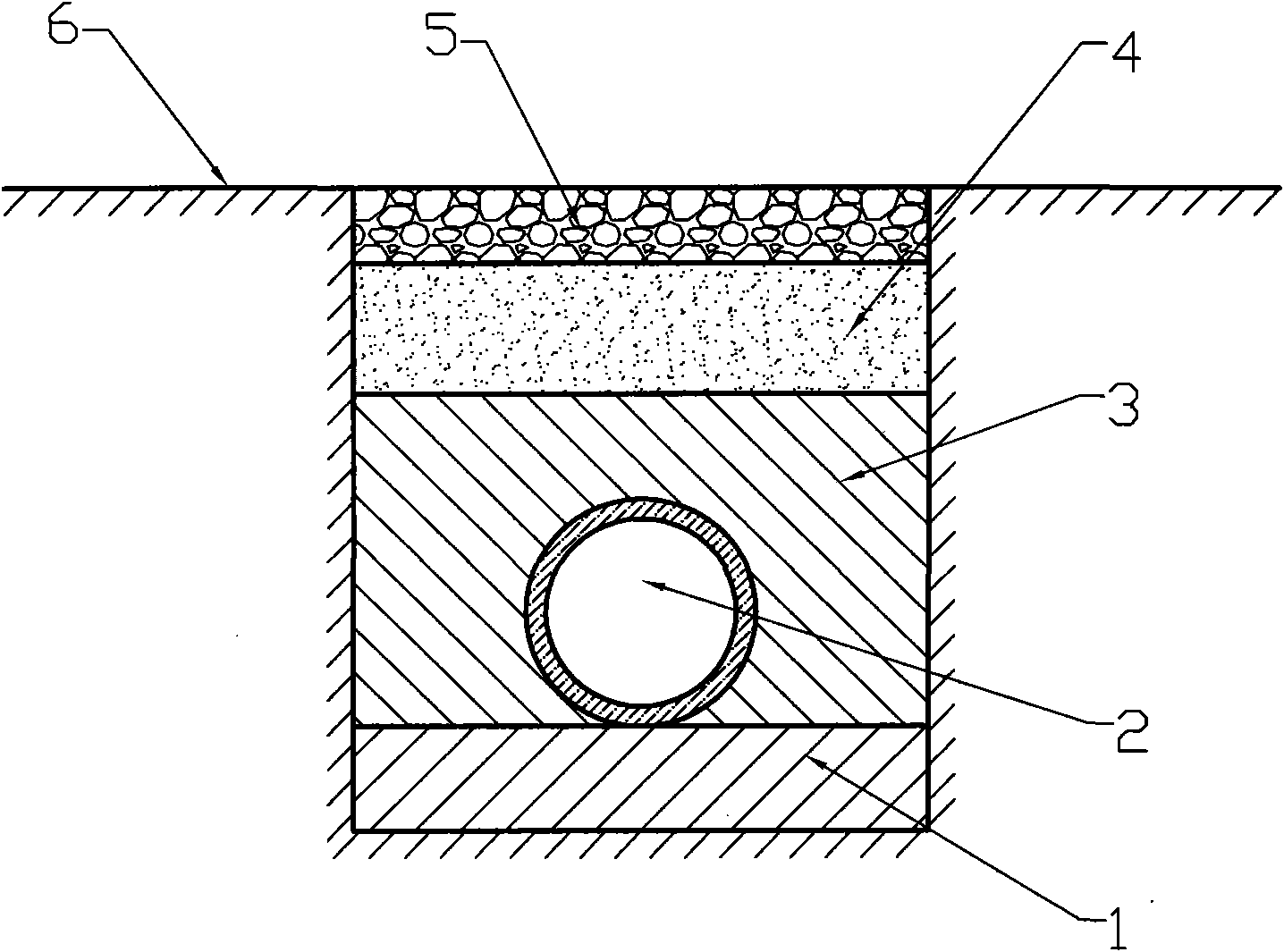

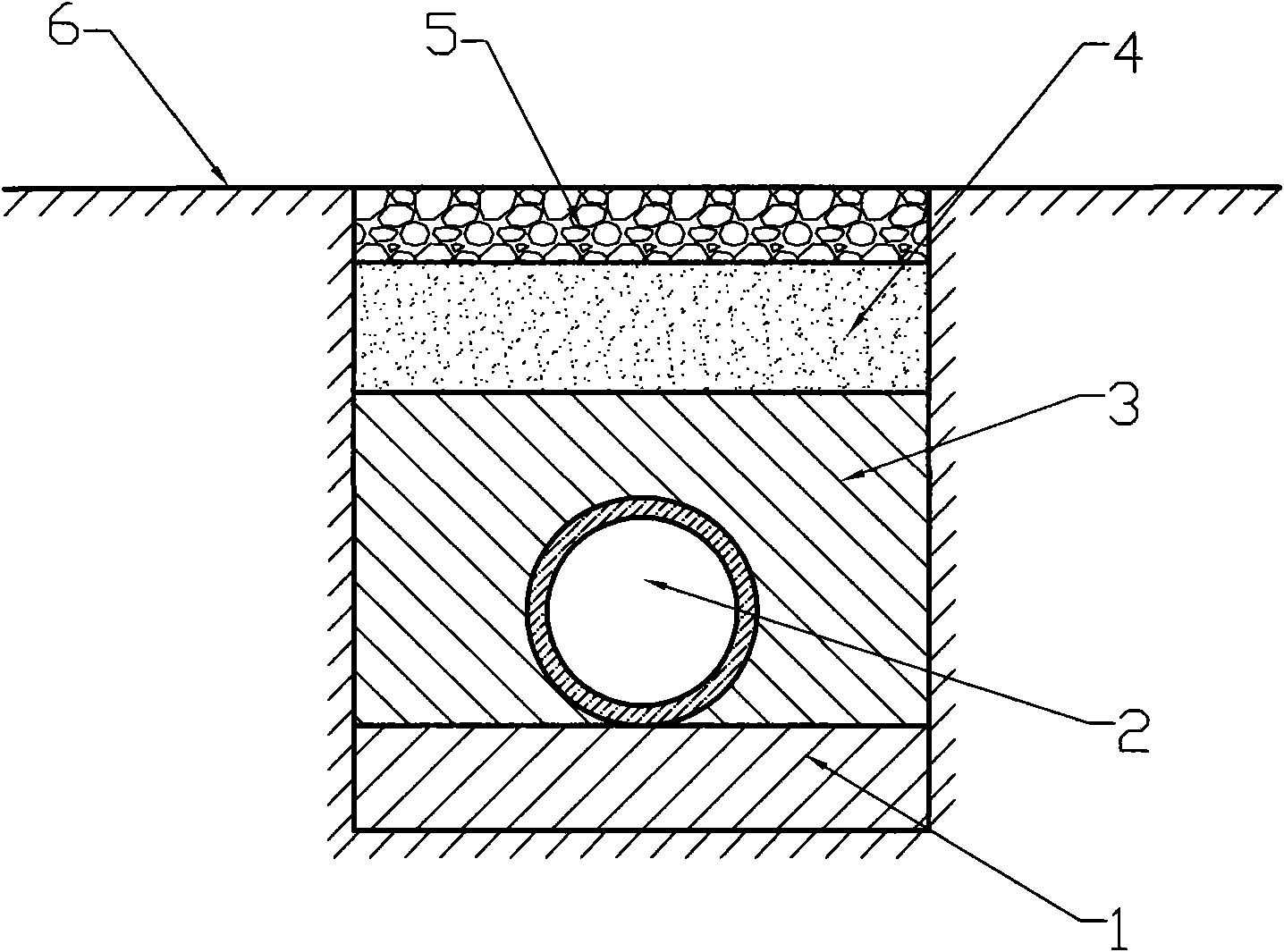

[0023] Such as figure 1 shown.

[0024] 1. Technical preparations before construction. Before construction, you should be familiar with and master the construction drawings, prepare construction machines and tools, conduct on-the-job training for operators, and inspect and accept pipes and pipe fittings according to standards.

[0025] 2. Excavate the foundation. Excavate a pipe trench with a rectangular section on the ground, and the excavation of the pipe trench must be carried out in strict accordance with the design drawings, or the excavation route and excavation depth guided by the engineering supervision. In order to ensure the accuracy of the foundation, pipes are drawn on the ground before excavation.

[0026] The pressure-bearing flexible pipe of the plastic flexible pipe has a large diameter, a thick wall, and a light weight, so a long pipeline can be prefabricated on the ground. The width and depth of the pipeline are designed by the technical personnel accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com