Active-omni-directional-vision-based pipeline inside functional defect detection device and detection method

An active panorama and defect detection technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as low level of automation and intelligence, and difficulty in three-dimensional modeling of the inner side wall of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

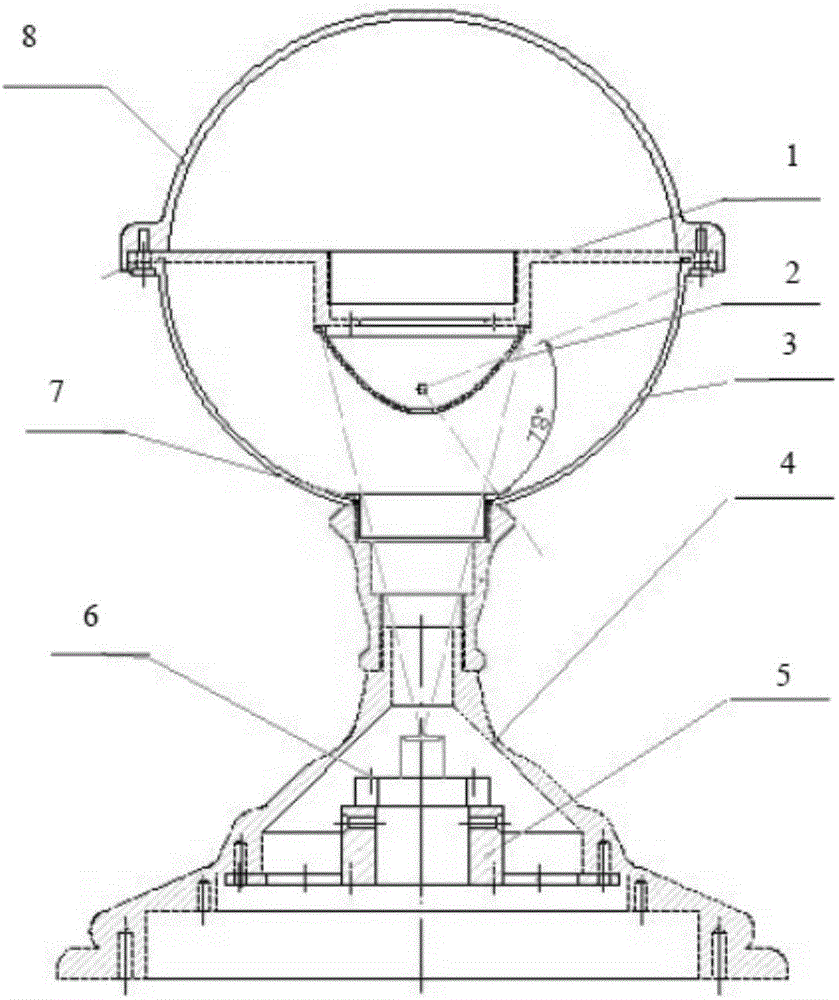

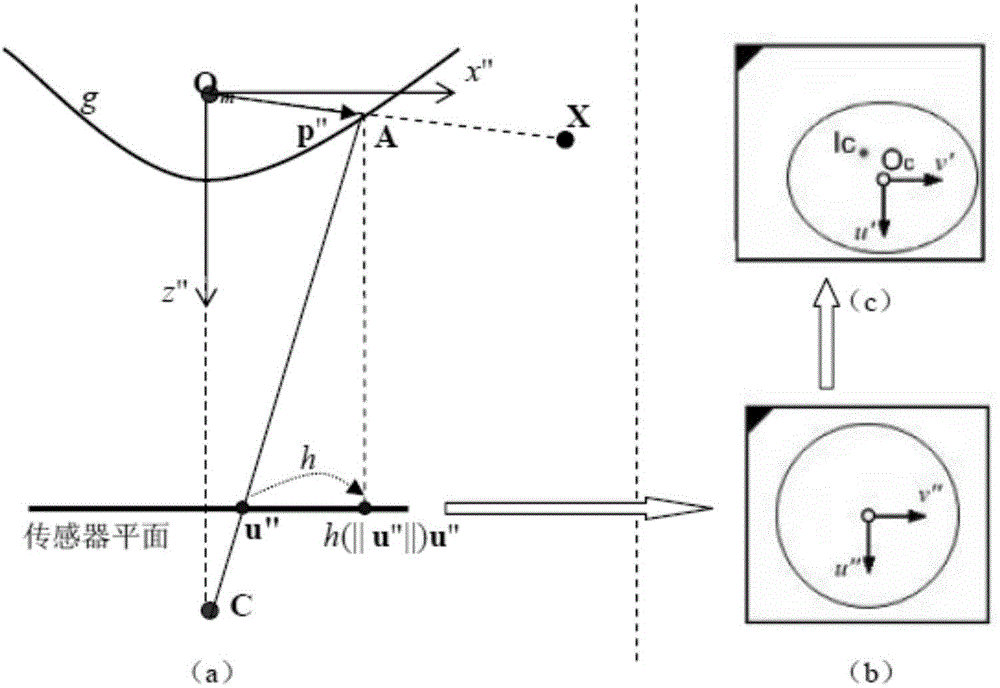

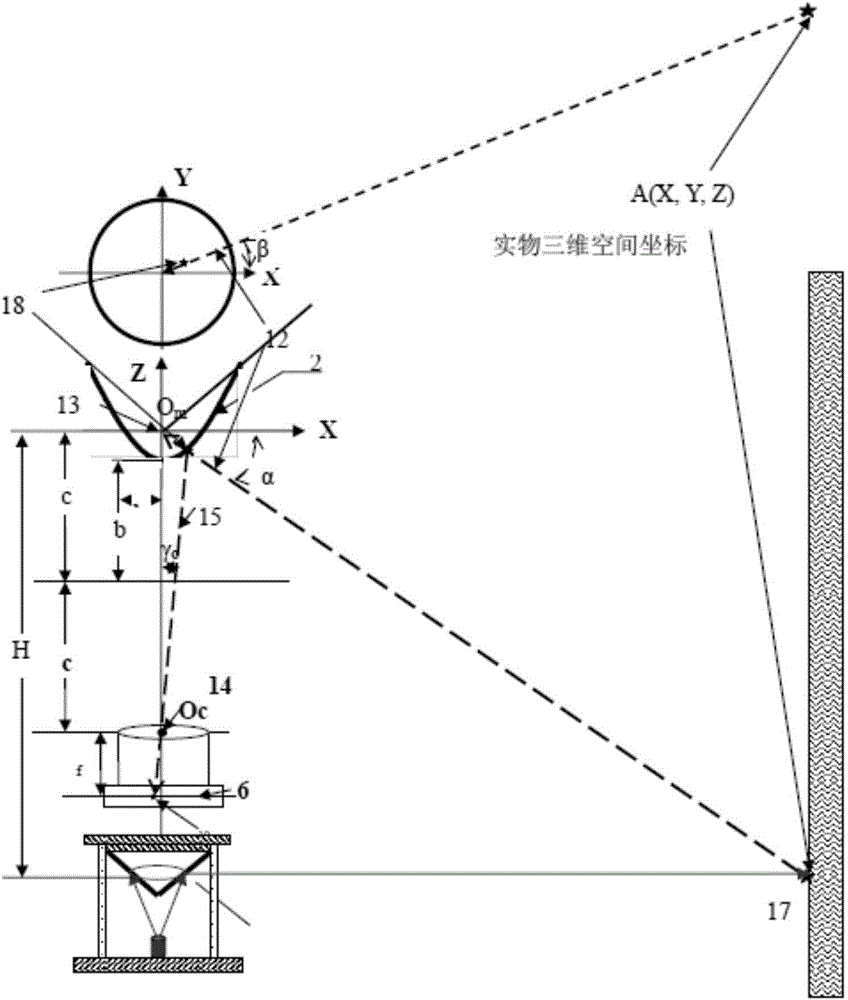

Embodiment 1

[0111] refer to Figure 1-9 , a device and method for qualitative and quantitative detection of functional defects and structural defects in pipelines based on active panoramic vision, its hardware includes: camera crawling system, control cable and core operating system for detection and analysis: The panoramic vision sensor is advanced to the inside of the pipeline, and the active panoramic vision sensor captures the panoramic image inside the pipeline and the laser scanning section slice image, and transmits the image to the console in a timely manner; the control cable is responsible for transmitting the crawling equipment instructions and real-time panoramic image data in the pipeline; The detection and analysis core operating system is responsible for issuing control commands, such as crawling system forward, backward, camera system lighting, etc.; accepts image data and processes the image data, and finally stores the image data and analysis results to the storage device...

Embodiment 2

[0256] In this embodiment, the rest of the implementations are similar, the difference is that the camera crawling system has multiple modes of wheel type, foot type, crawling type, peristaltic type and crawler type according to the situation of the pipeline.

Embodiment 3

[0258] In this embodiment, other implementations are similar, the difference is that the camera crawling system adjusts the installation height of the fixed active panoramic vision sensor according to the size of the pipe diameter, so that the axis of the active panoramic vision sensor and the axis of the pipeline The lines basically match.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com