Steel reinforcement cage for multi-ribbed composite wall and method for installing steel reinforcement cage

A reinforcement cage and composite wall technology, applied in the processing of walls and building materials, structural elements, etc., can solve the problems of excessive manpower and working hours, difficulty in improving the construction speed of manual binding of steel bars, and complicated binding procedures, etc., to ensure that Quality, faster binding or welding speed, easy quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

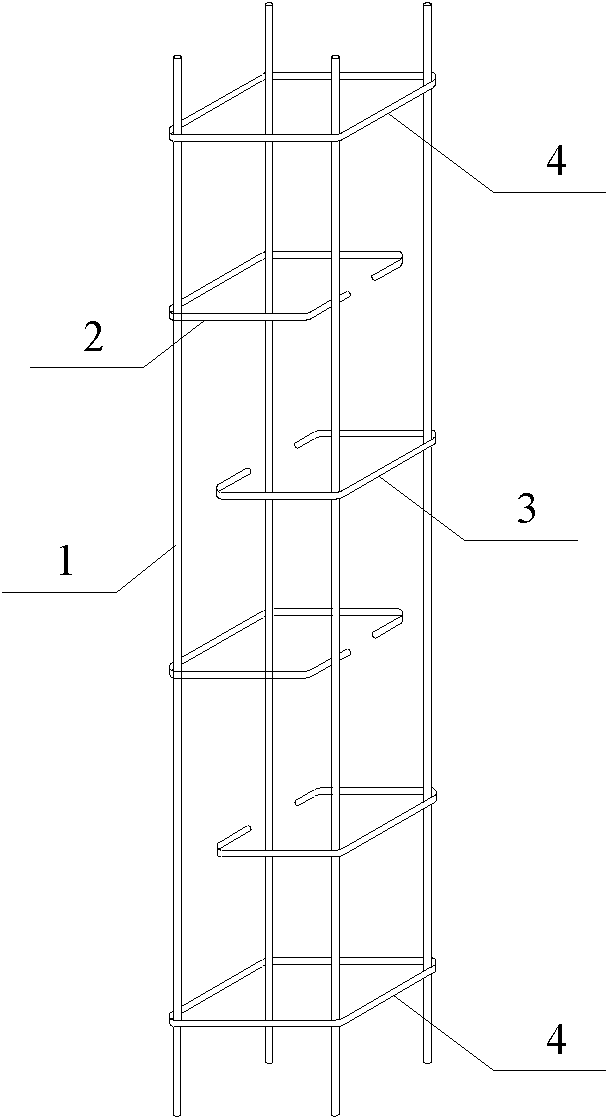

[0040] The steel cage of the present invention is arranged inside the rib beam or the rib column of the multi-ribbed composite wall. The length of the steel cage is equal to the length of the rib beam or column.

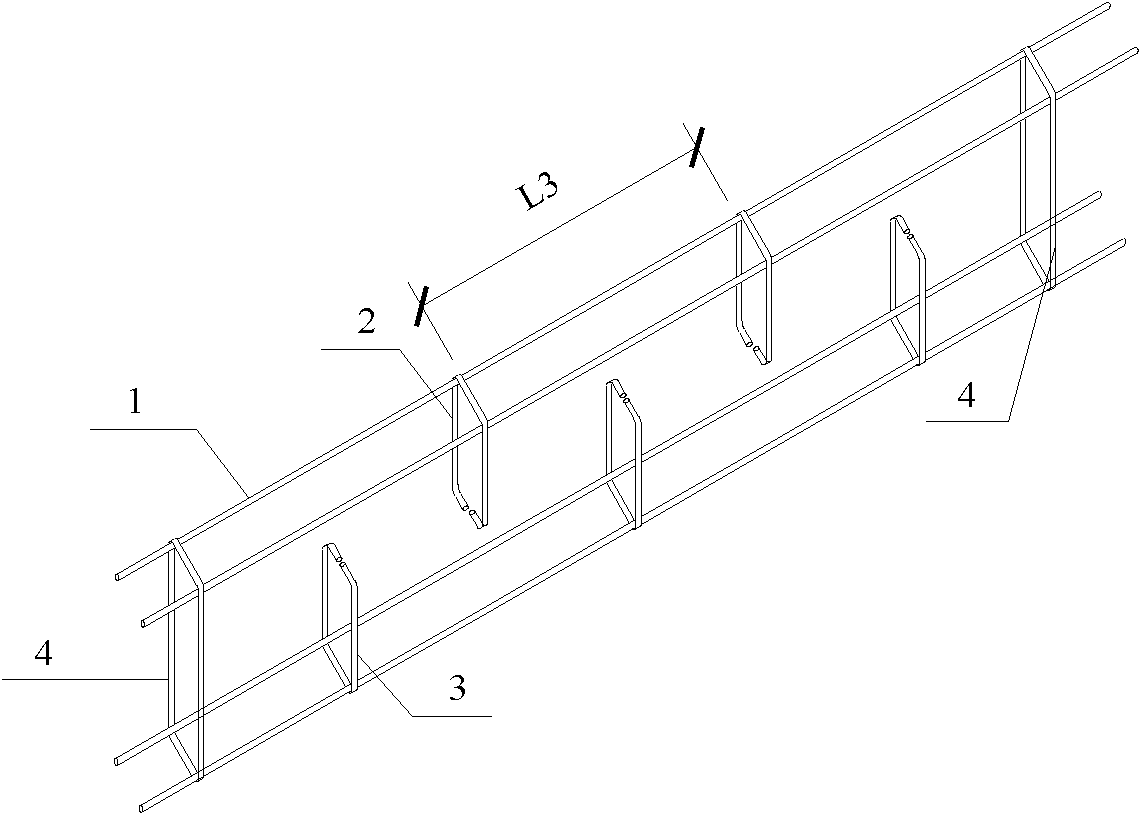

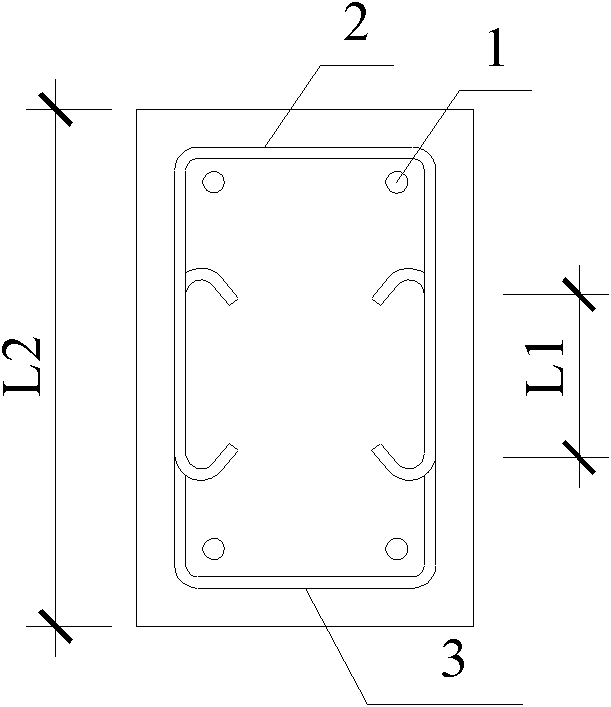

[0041] Reference figure 1 , Shows a three-dimensional structural diagram of Embodiment 1 of a steel cage for a multi-ribbed composite wall of the present invention. In this embodiment, the steel cage is arranged in the rib beam.

[0042] The steel cage includes: longitudinal steel bars 1, a first half-ring stirrup 2, a second half-ring stirrup 3, and a positioning closed stirrup 4; wherein the two sides and two bottom sides of the positioning closed stirrup 4 The first half-ring stirrup 2 is a groove shape with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com