Patents

Literature

32results about How to "No need to consume water resources" patented technology

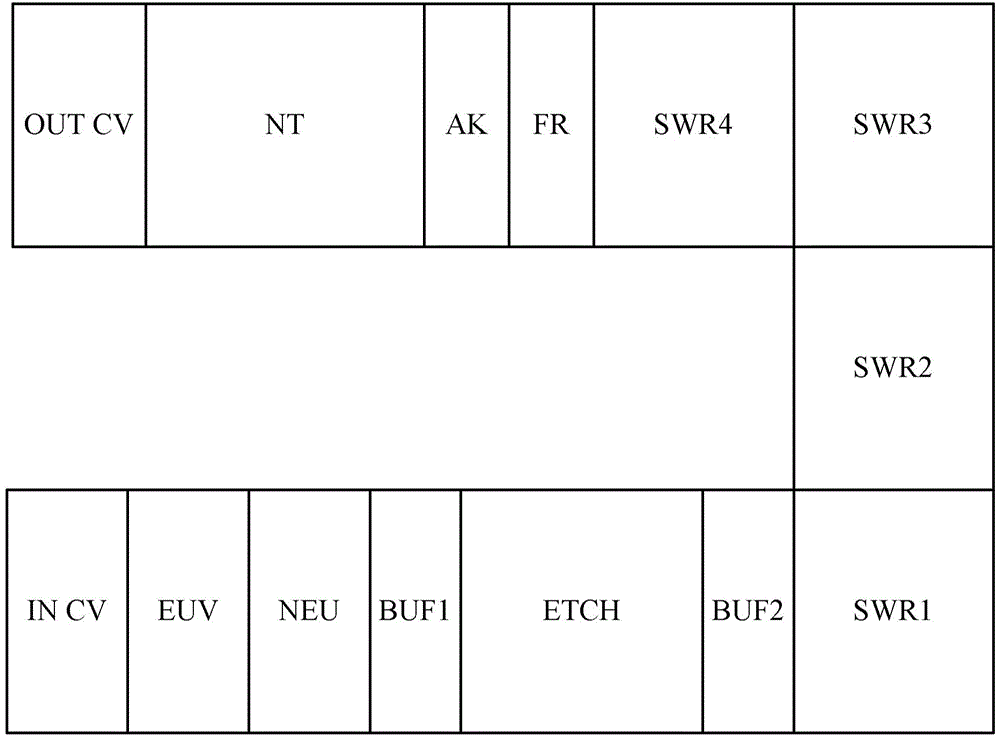

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

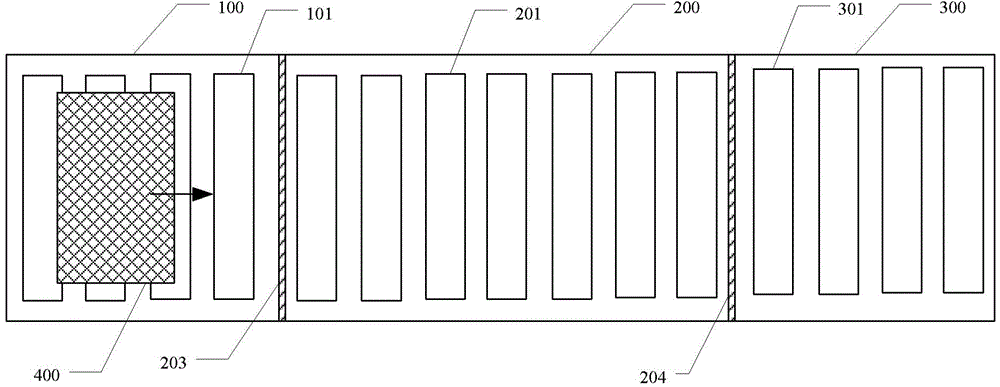

Wet etching equipment

ActiveCN104681471AEfficient removalImprove utilizationSemiconductor/solid-state device manufacturingManufacturing technologyLiquid crystal

The invention provides wet etching equipment. The wet etching equipment has a function of removing etching liquid crystal outside an etching chamber, and comprises the etching chamber and a spray pipe, wherein a film to be etched is etched through etching liquor inside the etching chamber; an etching chamber inlet is formed in the front end of the etching chamber; an etching chamber outlet is formed in the rear end of the etching chamber; the spray pipe is arranged below the etching chamber inlet and / or the etching chamber outlet, and can be towards to the upper part to spray liquid, so as to clean etching liquid crystal formed at the etching chamber inlet and / or the etching chamber outlet. The wet etching equipment adopts the spray pipe to spray the etching chamber inlet and the etching chamber outlet, can effectively remove a large amount of etching liquid crystal produced at the etching chamber inlet and the etching chamber outlet, improves the equipment operation ratio, cleanness and product quality, and solves a major problem in a TFT base substrate manufacture technology.

Owner:BOE TECH GRP CO LTD

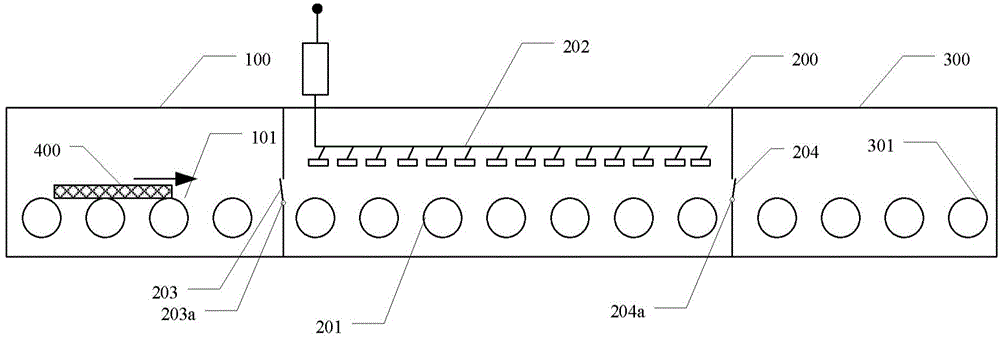

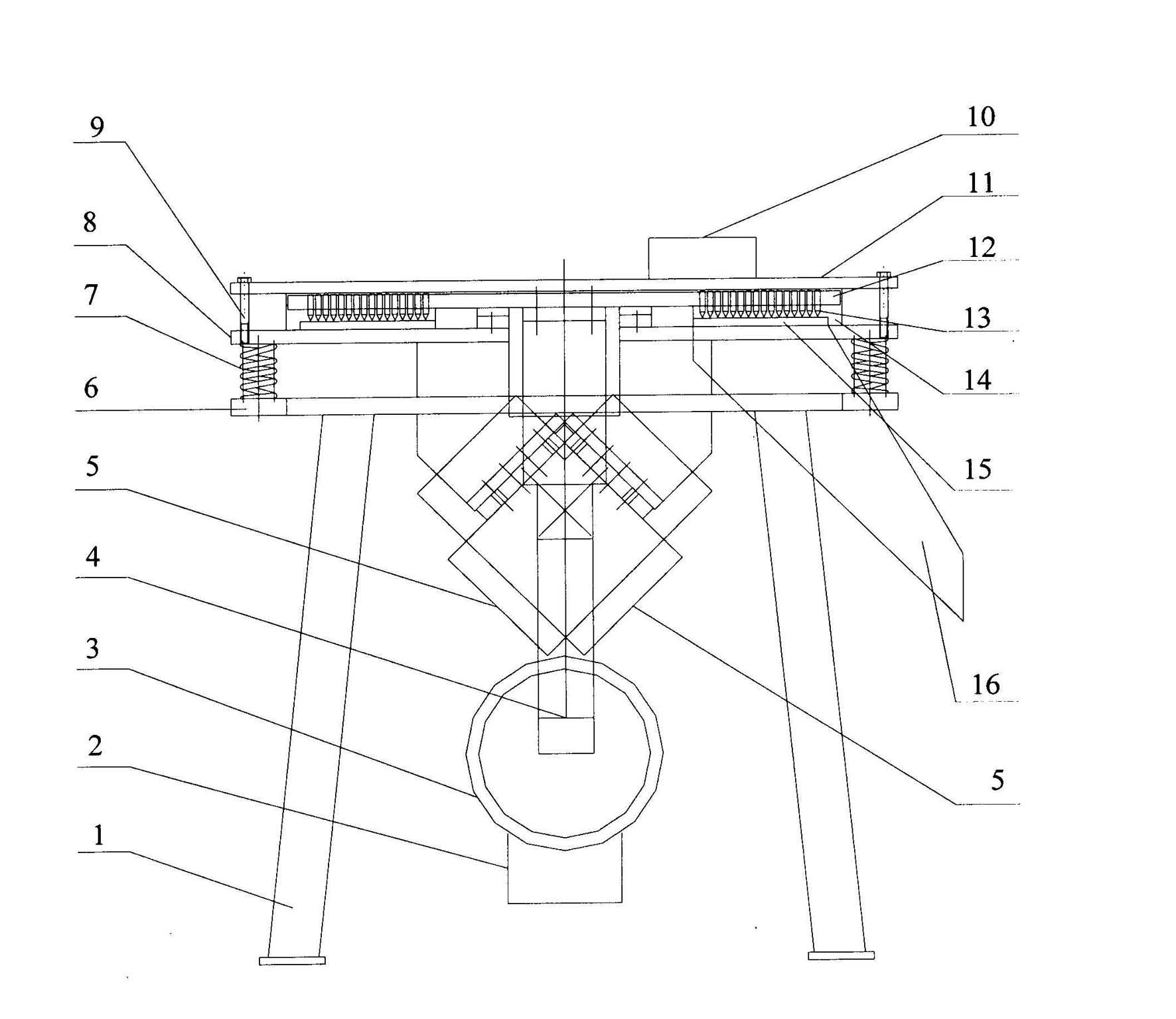

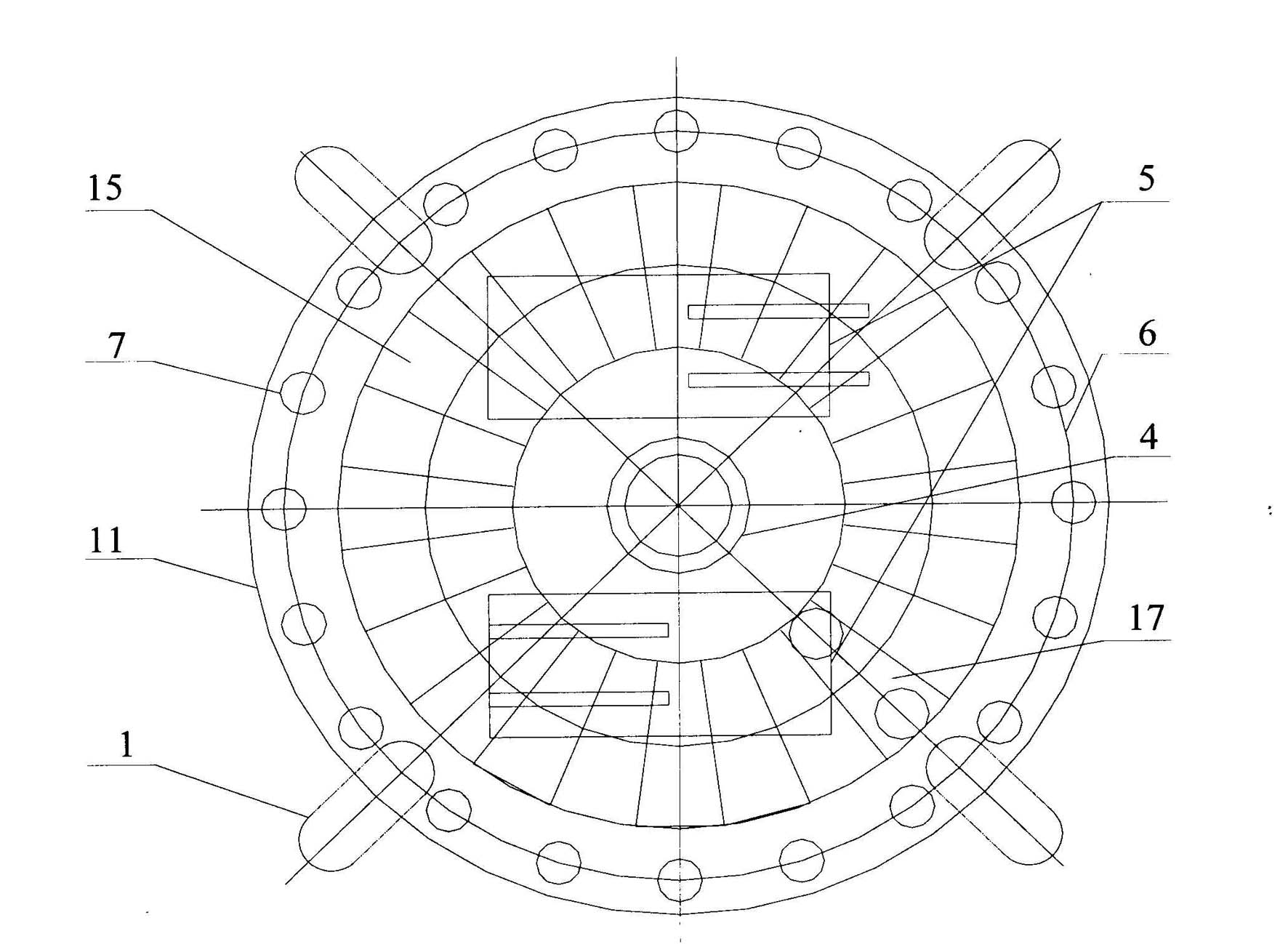

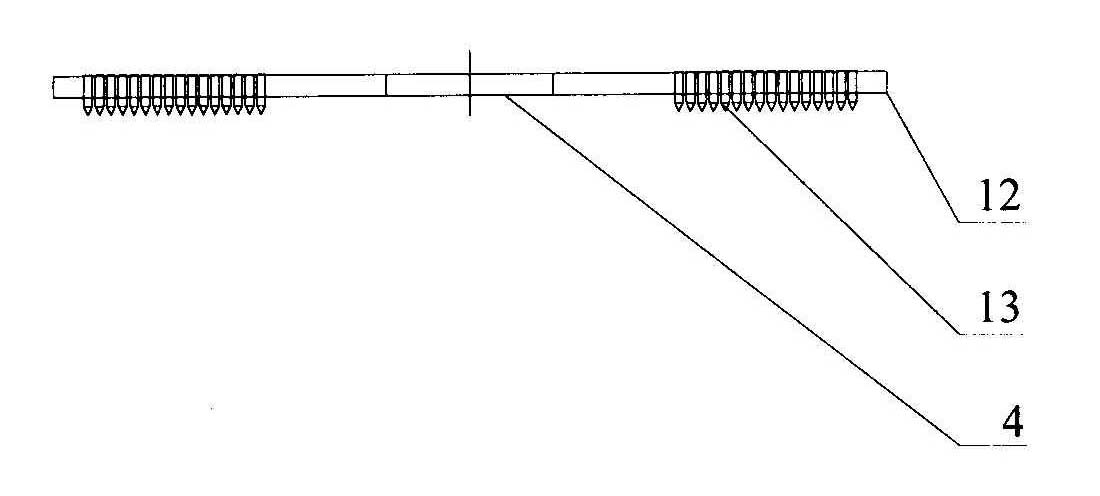

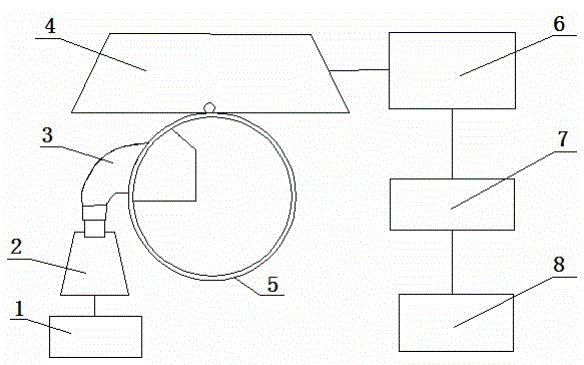

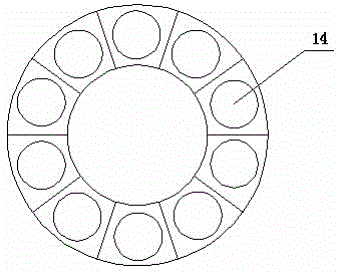

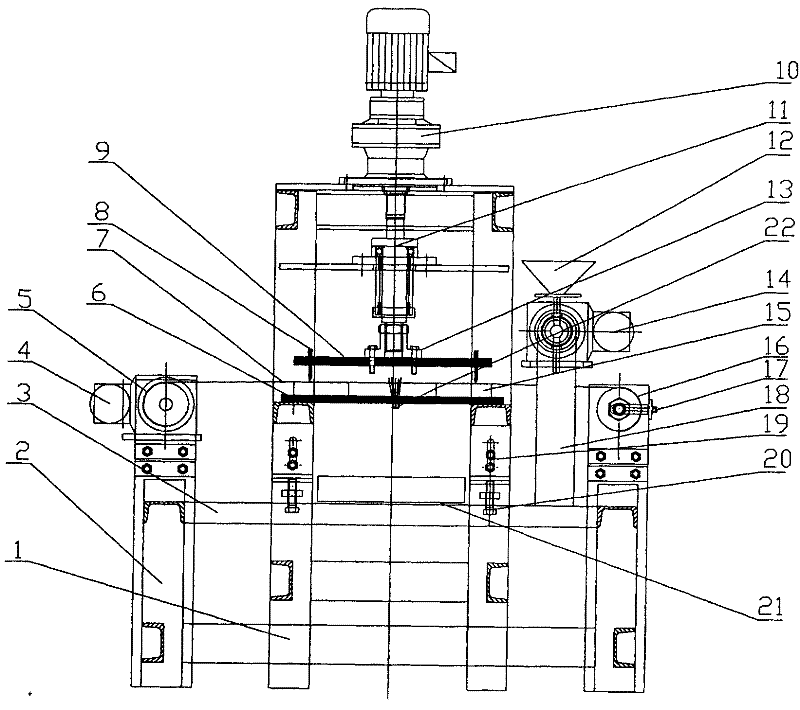

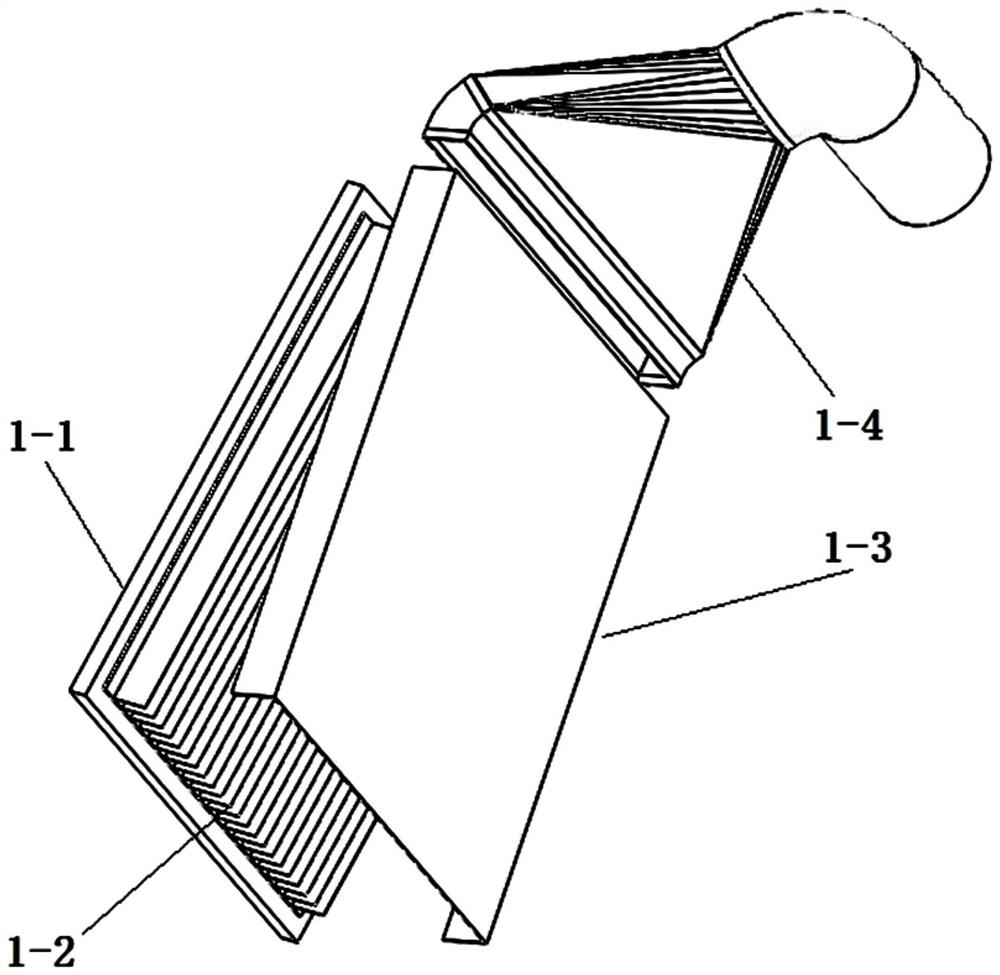

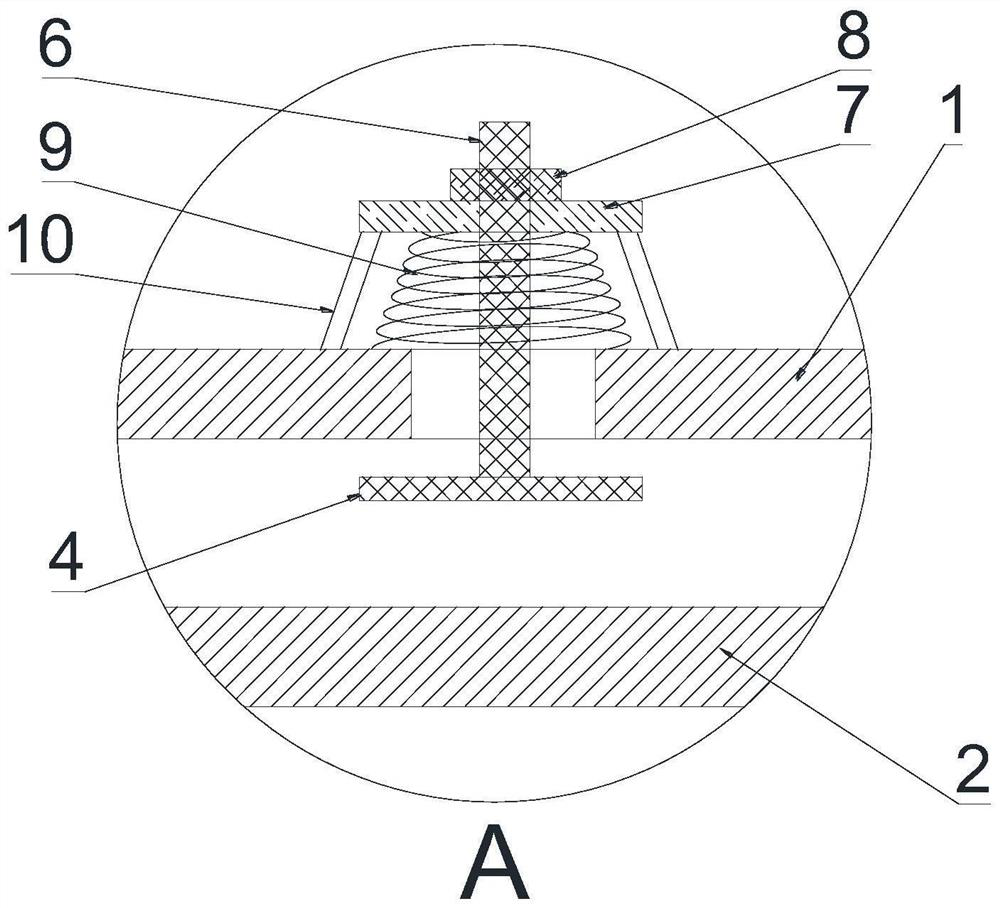

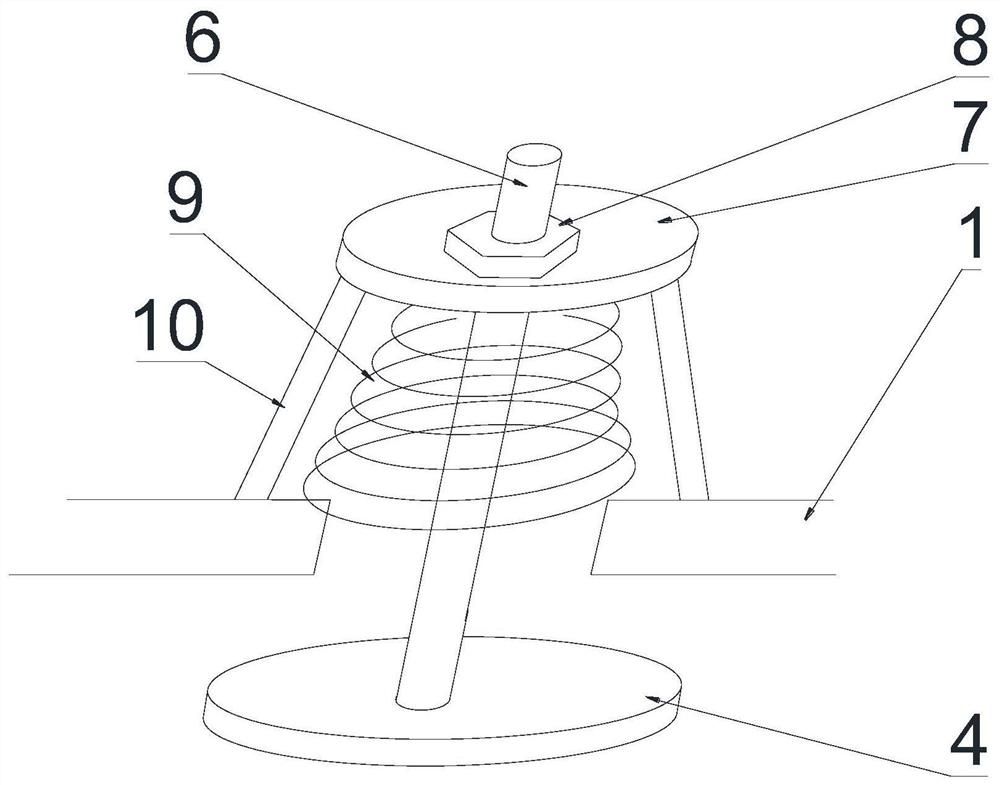

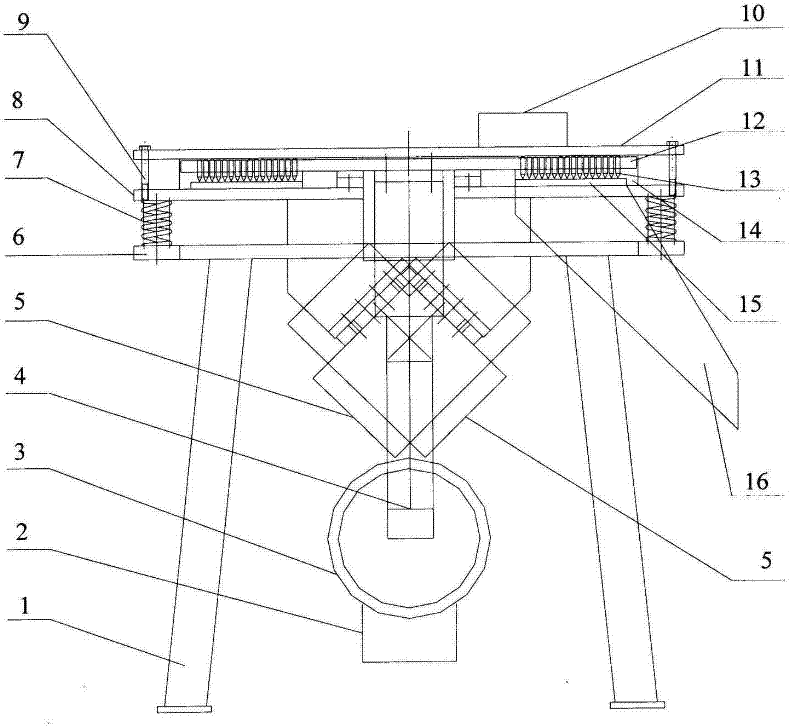

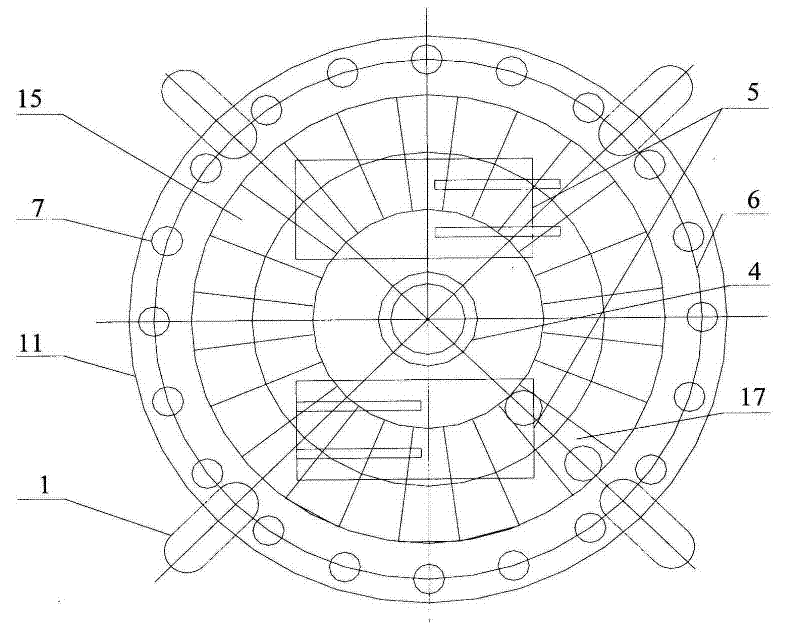

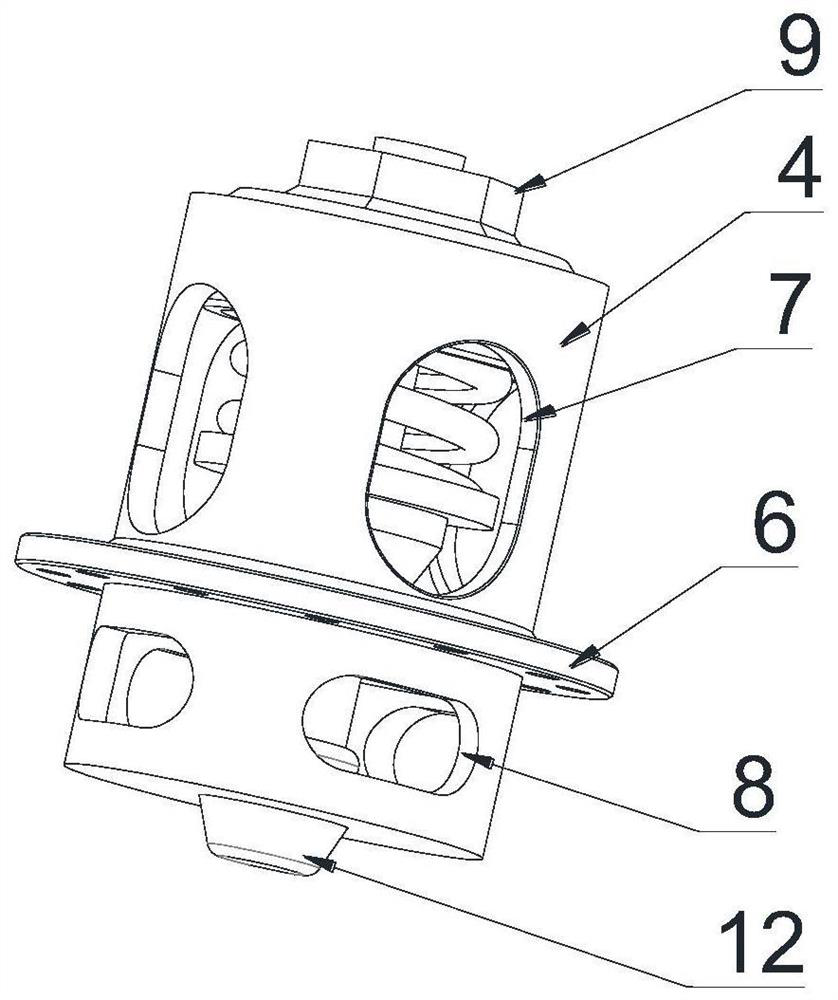

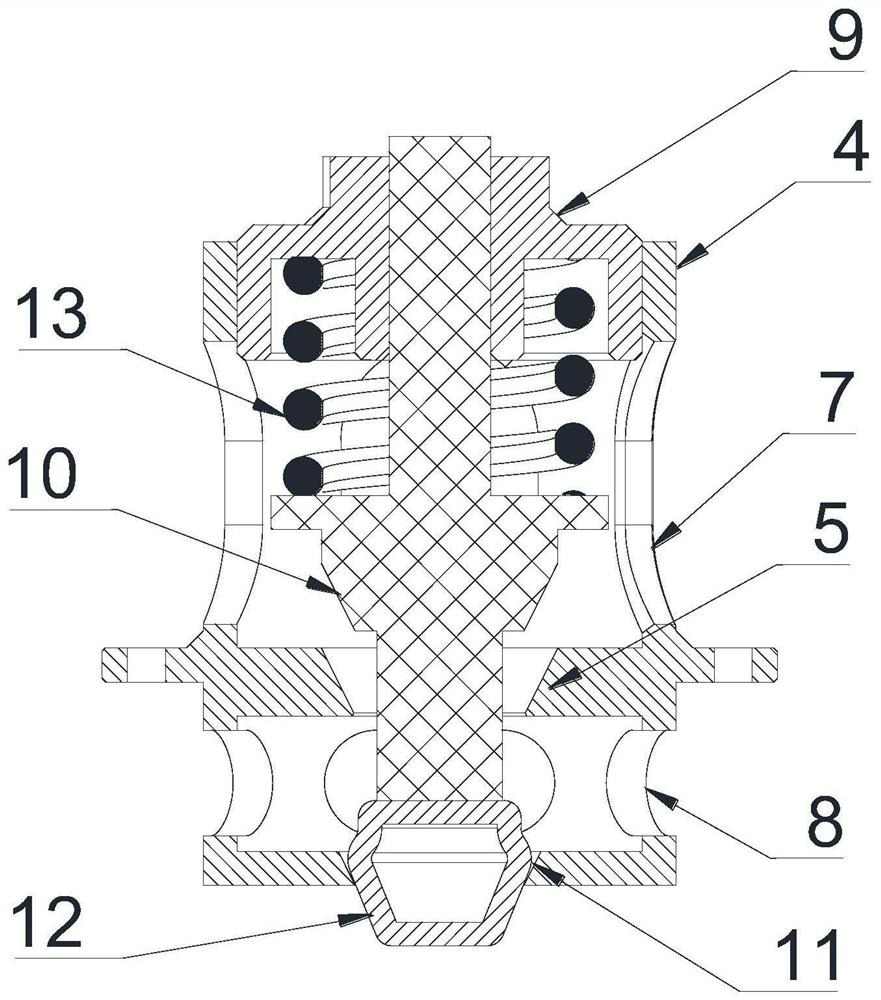

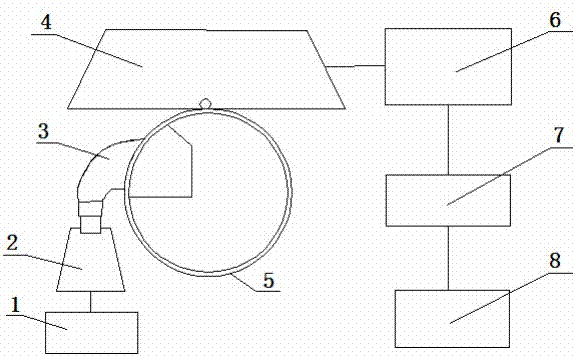

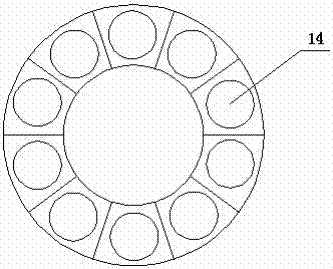

Permanent magnetic high-gradient comprehensive force field separator with disc structure

InactiveCN101947492AReduce cost and energy consumptionSimplify the mechanical structure of the equipmentHigh gradient magnetic separatorsEngineeringElectrical and Electronics engineering

The invention relates to a permanent magnetic high-gradient comprehensive force field separator with a disc structure, which comprises a support, a supporting substrate, a plurality of damping springs, a magnetic disc, a magnetism gathering nail rotating disc, a top layer circular ring disc, a guide shaft sleeve and a transmission shaft, wherein the supporting substrate is in a circular ring-shaped structure and arranged on the support, the plurality of the damping springs are arranged by surrounding the circumference of the supporting substrate, the magnetic disc is mounted above the supporting substrate, the magnetism gathering nail rotating disc and the top layer circular ring disc are sequentially mounted above the magnetic disc by clearance fit, the guide shaft sleeve is mounted below the magnetism gathering nail rotating disc, extends in a vertical downward manner and penetrates the central position of the magnetic disc, the transmission shaft supports a central hole of the supporting substrate, and the lower end of the transmission shaft is combined with a driving mechanism; the top layer circular ring disc is combined with the magnetic disc thorough a connecting part arranged by surrounding the periphery of the top layer circular ring disc, and the bottom surface of the magnetic disc is combined with a vibrating motor arranged below the supporting substrate through the connecting part; a feeding device is arranged on one side above the top layer circular ring disc; and a non-magnetic material receiving device is mounted below the magnetic disc, and the mounting position of the non-magnetic material receiving device is in upper-lower corresponding with the mounting position of the feeding device.

Owner:HENAN POLYTECHNIC UNIV

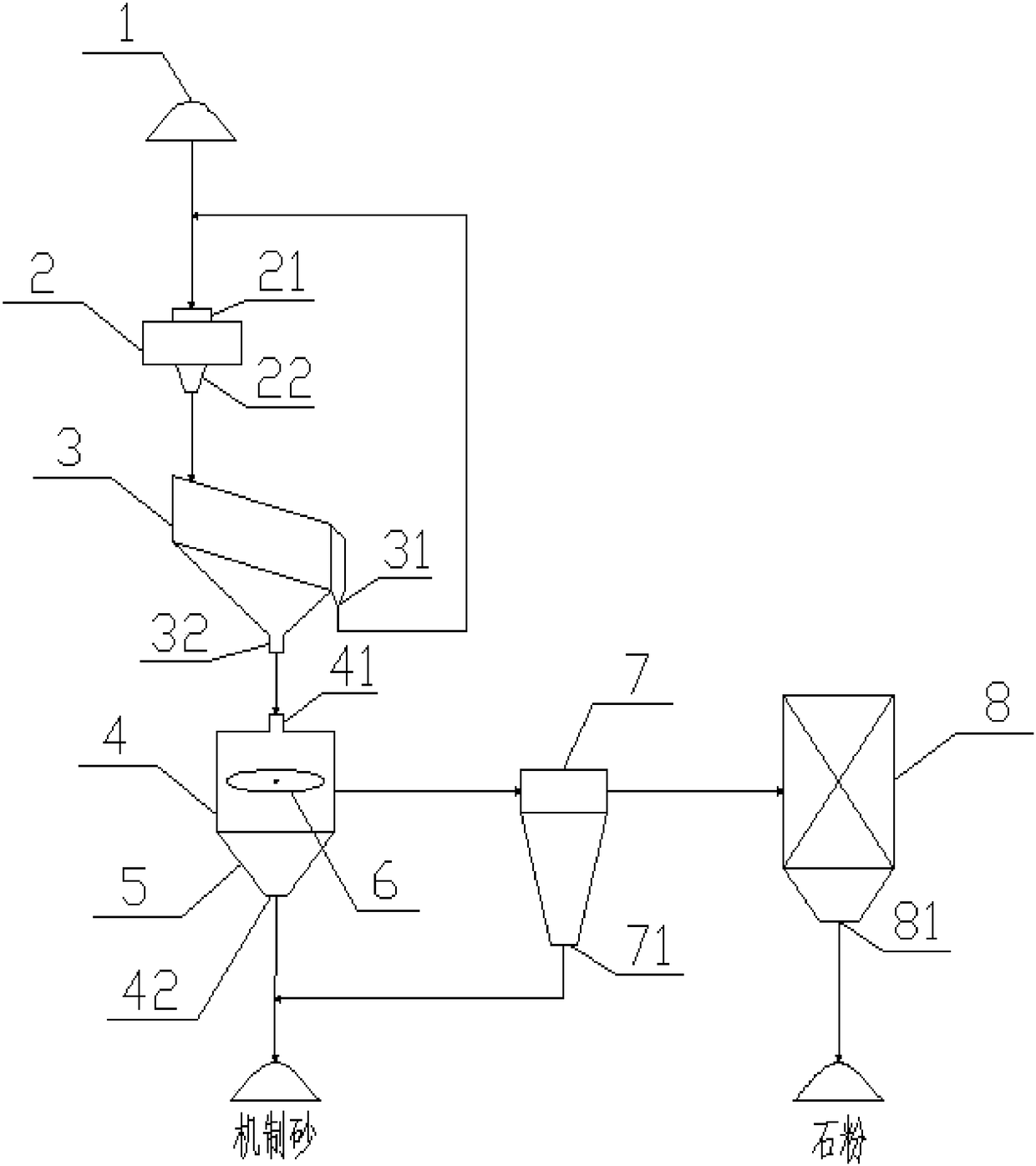

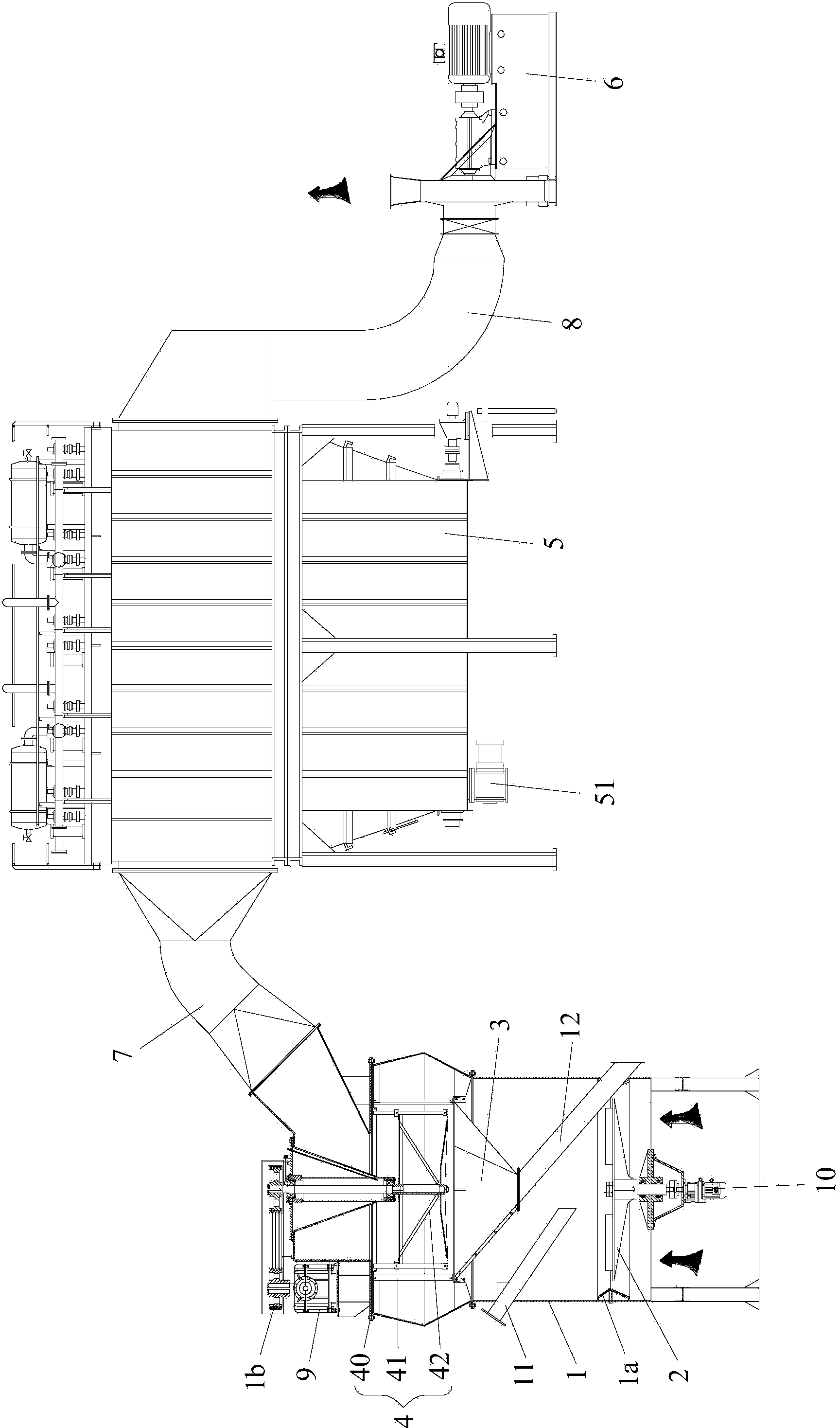

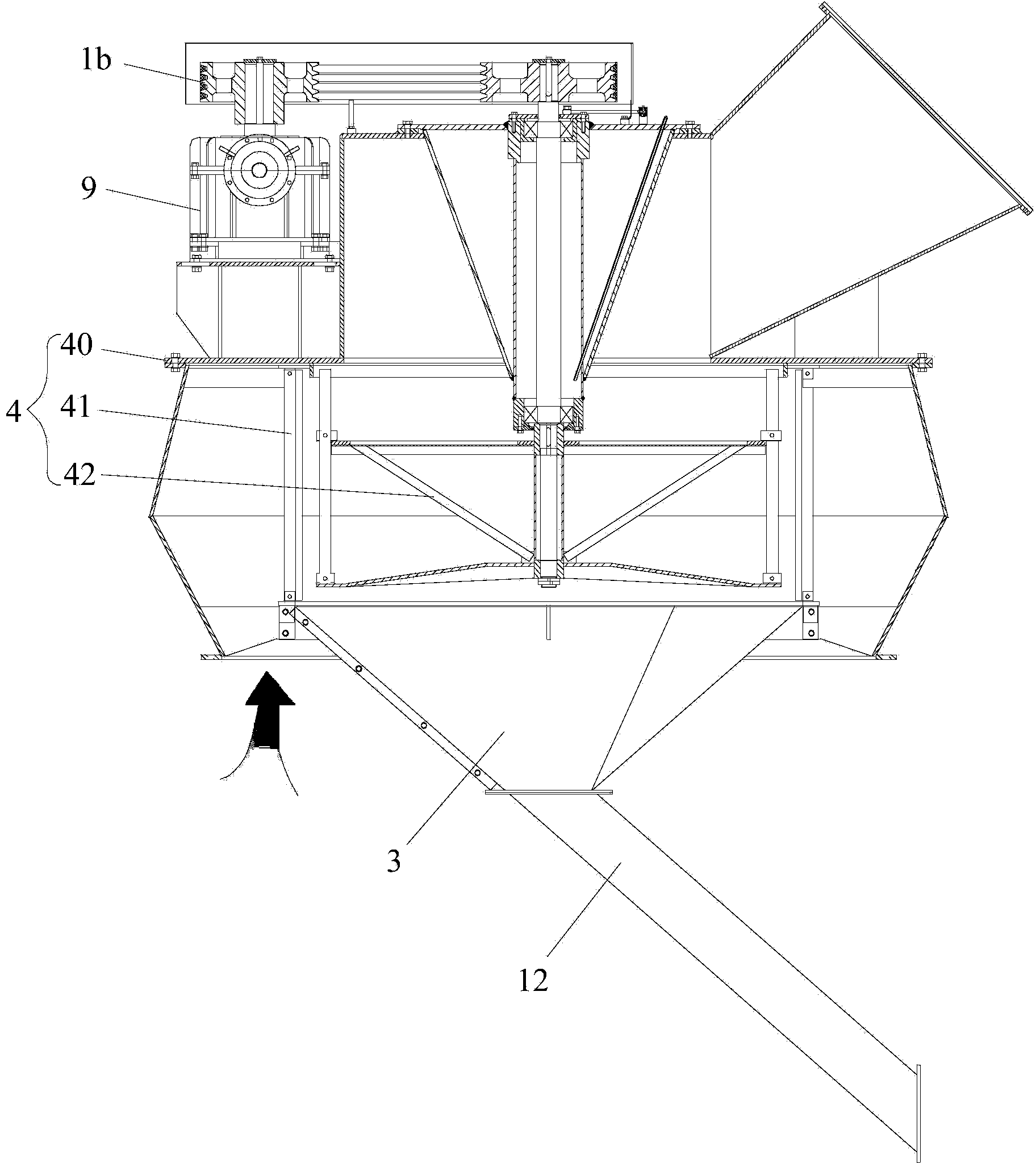

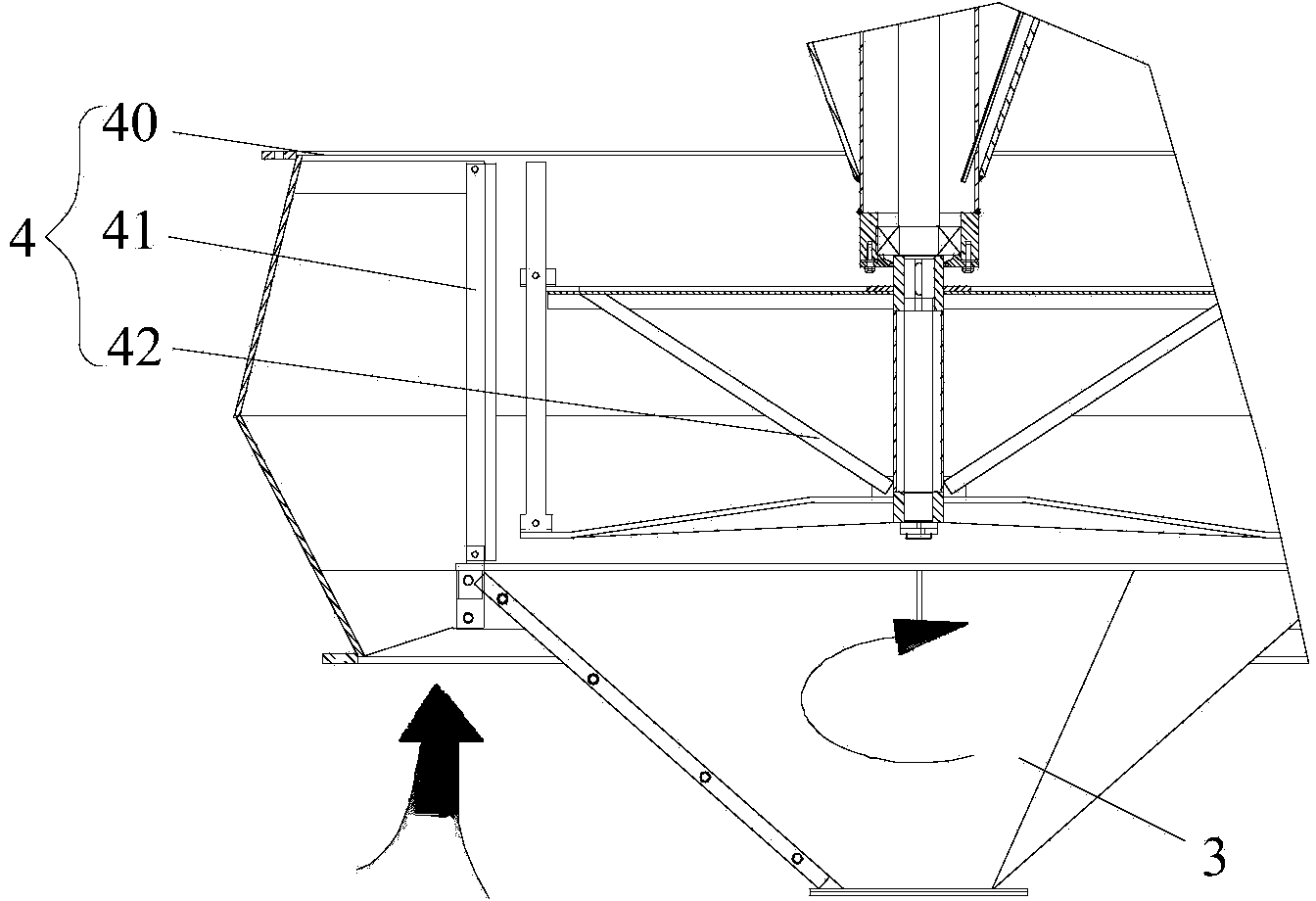

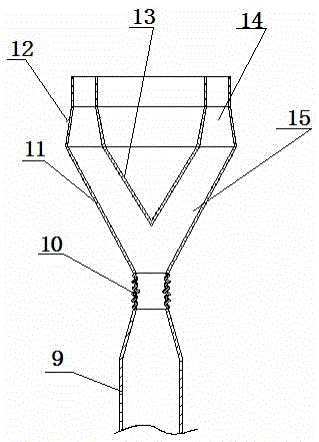

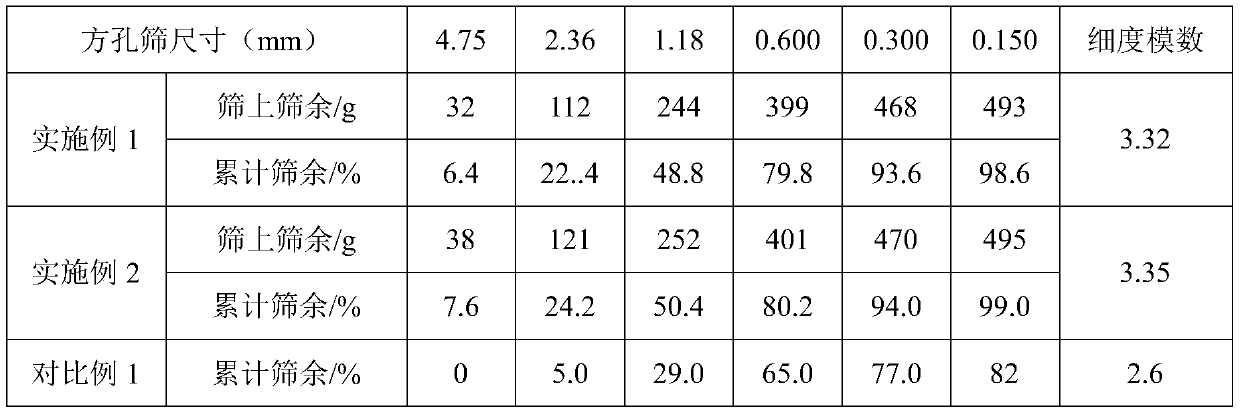

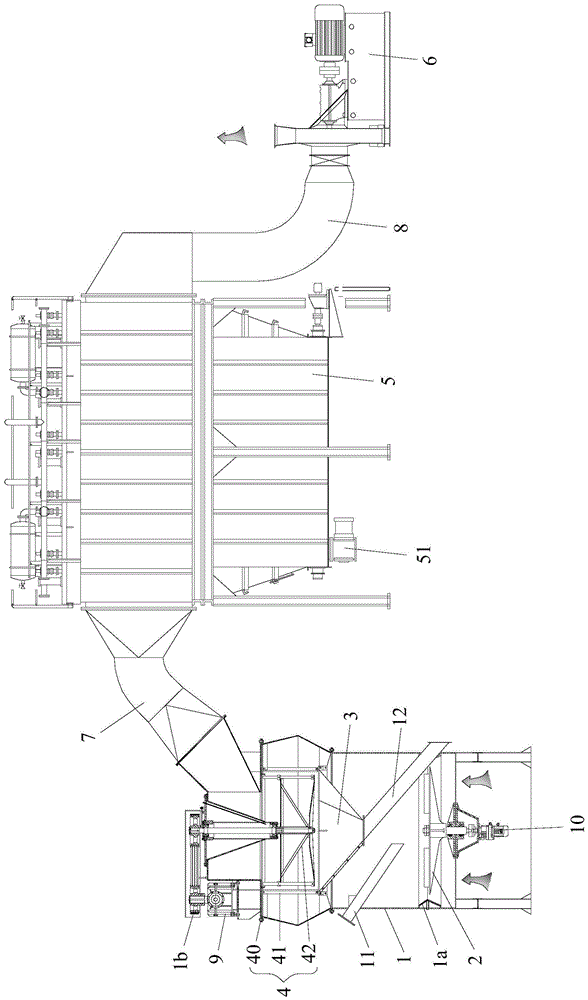

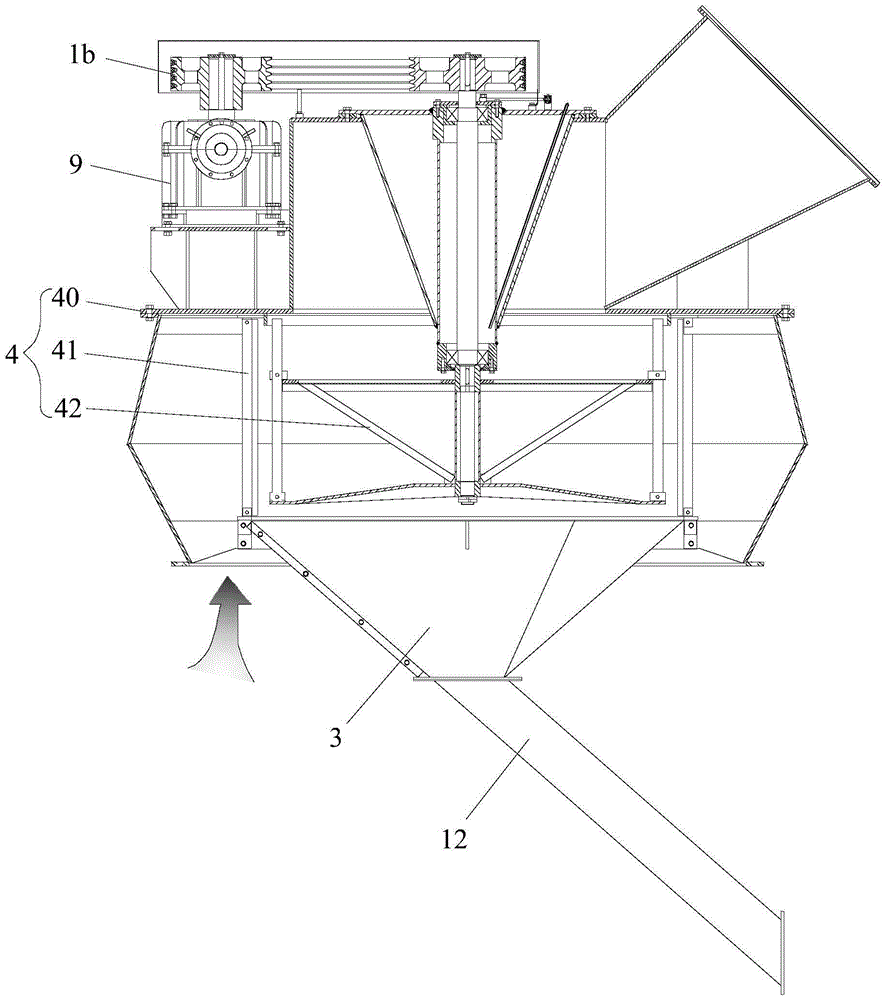

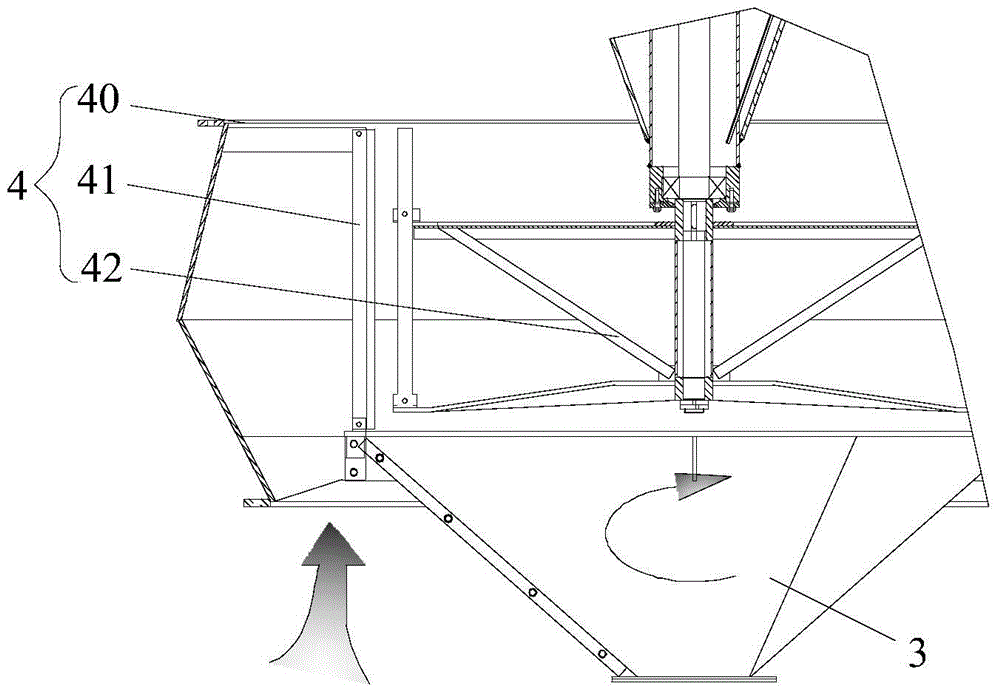

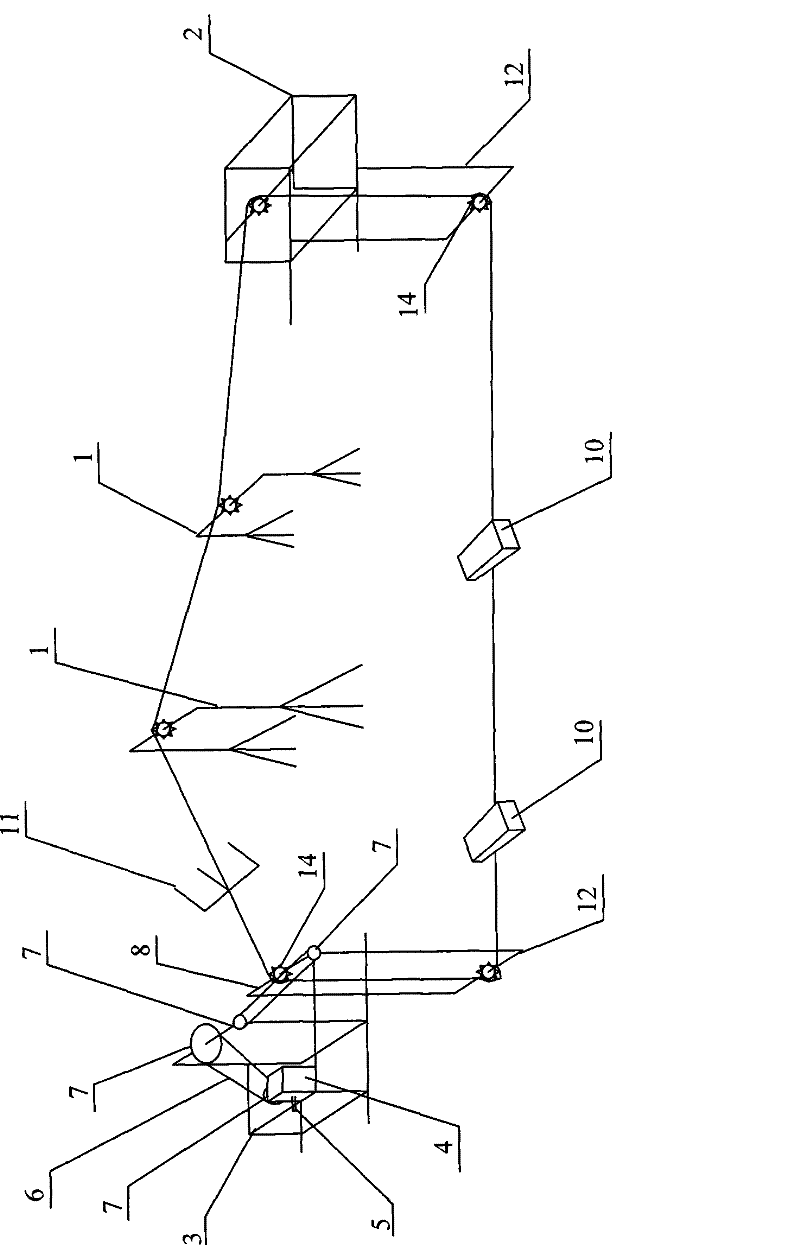

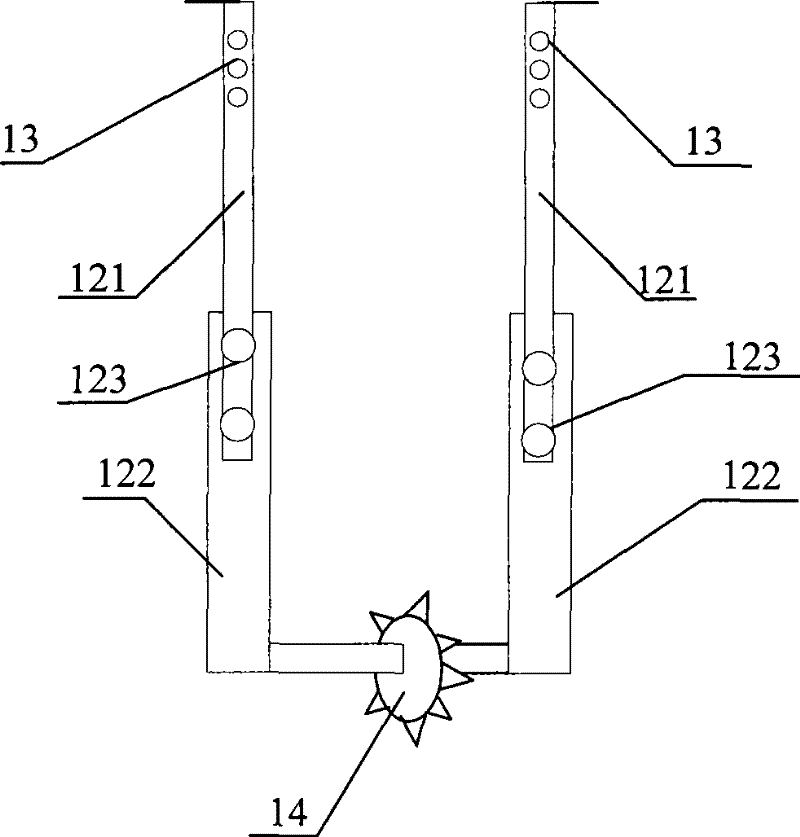

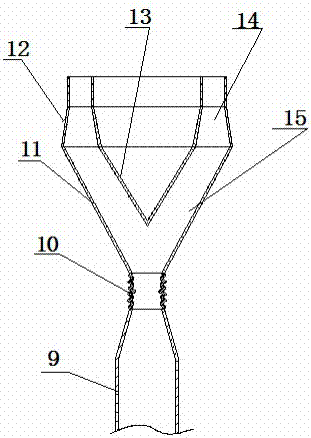

Production device for machine-made sand for high-performance concrete

PendingCN108191278AAchieve coarse and fine separationReduce contentHigh strength concreteProduction line

The invention provides a production device for machine-made sand for high-performance concrete. The production device comprises a crushing machine, a vibrating screen, a winnowing device, a powder selecting machine and a dust remover. The winnowing device is additionally arranged at the tail end of a gravel production line, only fine grains obtained after crushing and separating are winnowed, andthus the energy consumption can be reduced; then, powder selecting is conducted through the powder selecting machine, the fine stone powder part is collected and stored, the coarse stone powder part flows back into a machine-made sand finished product, and thus the grain grading of the machine-made sand can be improved. The stone powder content of the machine-made sand produced by the production device is obviously reduced, so that the preparation of the high-performance concrete and high-strength concrete is facilitated, the water consumption of concrete per cubic meter is reduced, and the workability of the concrete is improved; the coarse stone powder part in stone powder flows back into the machine-made sand, so that the reasonable grading of the machine-made sand is further guranateed; besides, the by-product fine stone powder can be recycled, and it is unnecessary to consume a lot of water resources.

Owner:贵州涟江源建材有限公司 +1

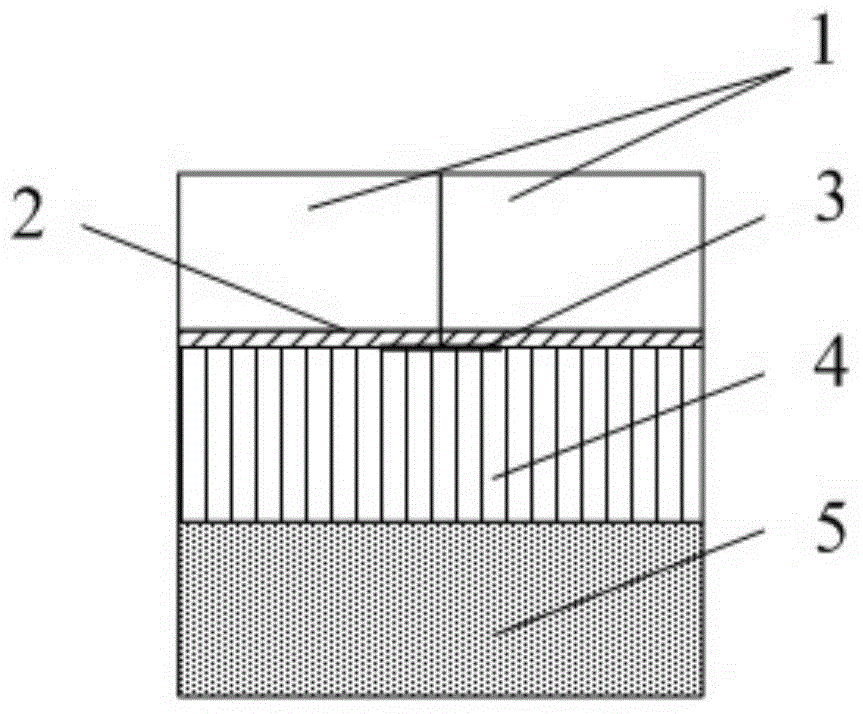

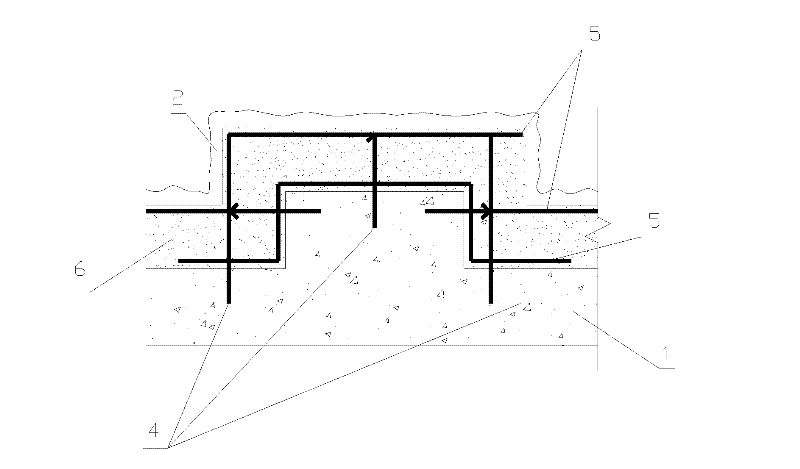

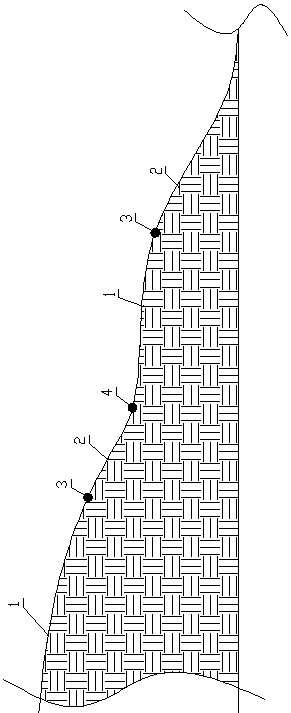

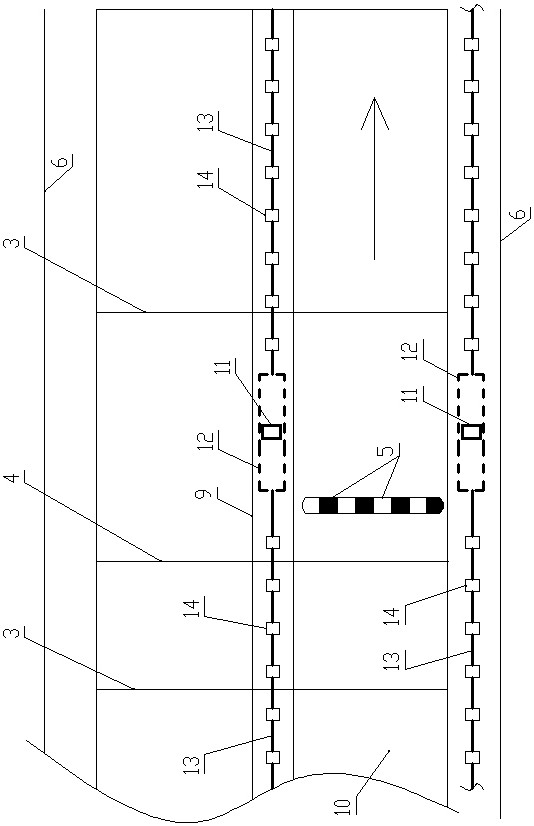

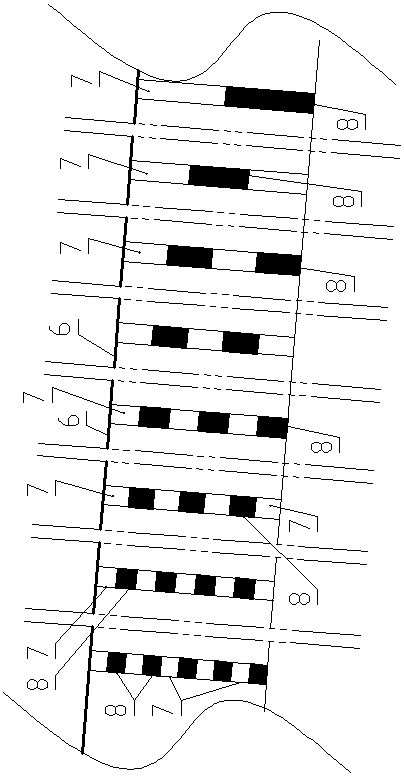

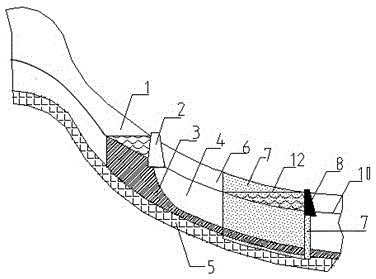

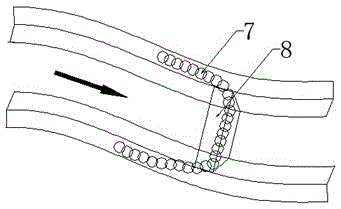

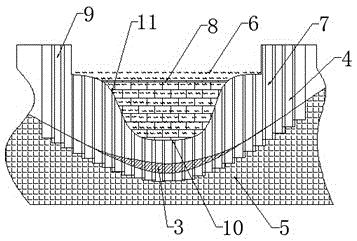

Assembly asphalt pavement for desert highway and construction method of assembly asphalt pavement

InactiveCN104532716ARealize water-saving constructionNo need to consume water resourcesIn situ pavingsSingle unit pavingsWater savingRoad surface

The invention discloses an assembly asphalt pavement for a desert highway and a construction method of the assembly asphalt pavement. The asphalt pavement comprises an aeolian sand subgrade, wherein a macadam base and an asphalt pavement precast block combination layer are sequentially laid on the upper surface of the aeolian sand subgrade from bottom to top according to a laminated structure, and the asphalt pavement precast block combination layer is formed by assembling and paving a plurality of asphalt pavement precast blocks; a plurality of reinforcing units are laid on the upper surface of the macadam base, correspond to joints of every two asphalt pavement precast blocks one to one, and are used for reinforcing the joints of the asphalt pavement precast blocks, and the macadam base and the asphalt pavement precast block combination layer are fixed by bonding; each asphalt pavement precast block sequentially comprises an asphalt surface course and a base plate from top to bottom according to a laminated structure, and each asphalt surface course and the corresponding base plate are fixed into a whole by bonding. The assembly asphalt pavement provided by the invention has the advantages of water-saving construction, prolonged construction season, rapid construction, rapid maintenance and the like.

Owner:SOUTH CHINA UNIV OF TECH

High-efficiency saline-alkaline soil improvement method

The invention relates to the technical field of soil treatment, and particularly relates to a high-efficiency saline-alkaline soil improvement method. The method comprises the following steps that desulfurized gypsum, zeolite and vinegar residues are mixed; then gluconic acid, expired yogurt and grape skin are added; the gluconic acid, the expired yogurt and the grape skin are degraded under the action of nitrogen-fixing alcaligenes faecalis for generating a large amount of free hydrophilic carboxyl groups; the carboxyl groups are introduced into the surfaces of the desulfurized gypsum, the zeolite and the vinegar residues under the action of the microorganisms for improving the hydrophilicity; the carboxyl groups have a metal complexing property, and finally a fermentation product which has good hydrophilicity and can adsorb metal salts by complexing is obtained; the fermentation product is put into porous moso bamboos; the porous moso bamboos are buried in planting pits; and then saline-alkaline tolerant plants are planted in the planting pits, so that improvement on saline-alkaline soil is completed. Water in surrounding soil can be gathered and absorbed, so that an effect of water retention and moisture preservation is achieved. With the increase of the concentration of the water in the soil, the concentration of salt in the soil can be reduced, the alkalization degree is reduced, the pH value of the soil is buffered, and the purpose of improving the saline-alkaline property is achieved.

Owner:吴迪

Method for improving salt and alkali soil through halophyte

The invention relates to treatment of salt and alkali soil, in particular to a method for improving salt and alkali soil through halophyte. The method includes the steps that firstly, after seeds with the good maturity such as atriplex halimus are refrigerated and stored, the seeds are sowed in potted soil in a hill-seedling mode, the potted surfaces are covered with fine sand and sprayed with a water solution in a timing mode, the surface of the soil is kept wet, the seedlings with the height ranging from 7 cm to 10 cm are transplanted into pots with the salt and alkali soil to be treated, and pot culturing is conducted; secondly, the pots are transferred outdoors, planting is conducted on the salt and alkali soil required to be treated according to the border of 1 m multiplying by 1 m till the whole region is covered; thirdly, after the transplanted plants grow for 120 days and are mature, and the seeds are shed, the portions, above the roots, of the plants are collected to be aired so as to be made into forage feed, and the salt and alkali soil can be improved after being governed through the method for 2 to 3 years. The method has the advantages that the salt and alkali soil can be improved effectively, and the treatment effect is good; consumption of a great number of water resources is not needed, growth of crops in the follow-up process is not affected; and the method is easy to implement and low in required cost.

Owner:NORTHWEST INST OF ECO-ENVIRONMENT & RESOURCES CAS

Efficient dedusting separator of building man-made sand

InactiveCN104249058ANo wearNo pollution in the processGas current separationWater resourcesWorking environment

The invention discloses an efficient dedusting separator of building man-made sand, comprising a housing. A rotary scatterer plate and a sand collecting hopper are arranged inside the housing sequentially from top to bottom. The housing is provided with a feed passage between the scatterer plate and the sand collecting hopper. The housing is further provided with a finished sand discharge passage connected to the bottom of the sand collecting hopper. A sorting unit is arranged at the top of the housing. A bag collector and a fan are arranged outside the housing. An inlet of the bag collector is connected to an air outlet of the sorting unit through a first pipeline. An air inlet of the fan is connected to an outlet of the bag collector through a second pipeline. The bag collector is provided with a sand collection point. The efficient dedusting separator of building man-made sand requires no water resources, is low in energy consumption, free of dust pollution, free of mesh abrasion and high in separation efficiency and allows work environment to be greatly improved.

Owner:襄阳宇清重工装备有限公司

Anhydrous foam generator for shale oil and gas reservoir fracturing as well as application thereof

The invention discloses an anhydrous foam generator for shale oil and gas reservoir fracturing as well as application thereof. The anhydrous foam generator has the following structure: a sand adding port, a liquid CO2 second injection port and a safety valve are arranged at the top of a propping agent storage tank; the bottom of the propping agent storage tank communicates with a high-pressure gasand liquid mixer through a propping agent discharging pipe; the top of the propping agent storage tank communicates with a primary oscillator and a secondary oscillator through an exhaust pipe; a liquid CO2 first injection port, a N2 injection port and an anhydrous foam foaming agent injection port are formed in the side wall of the high-pressure gas and liquid mixer; and the side wall of the high-pressure gas and liquid mixer communicates with the primary oscillator through a liquid discharging pipe; and the primary oscillator, the secondary oscillator and a tertiary oscillator communicate with one another sequentially. According to the three tandem oscillation mode of the anhydrous foam generator, the anhydrous foam generator has the characteristic of efficient foaming, guarantees complete mixing of the liquid CO2, N2 and propping agent particles, enhances the foaming capability of the foaming agent for anhydrous foam fracturing, can generate uniform and compact anhydrous foam fracturing liquid, contributes to improving the fracturing efficacy and greatly reduces formation damage.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of high performance concrete machine-made sand

The invention relates to a preparation method of high performance concrete machine-made sand. The preparation method comprises the following steps: S1, storing incoming main raw material macadam or aggregate chips in a stacking shed to be naturally aired, and feeding the main raw material which is naturally aired to a discharging terrace funnel; S2, raising the temperature and reducing the temperature gradually to prepare lightweight aggregates (a fine aggregate I, a coarse aggregate I and a coarse aggregate II), then processing the lightweight aggregates, ground stones and an abrasive material to obtain machine-made sand; S3, adding winnowing equipment at the tail end of a gravel production line, winnowing fine particles which are crushed and separated only, then selecting powder througha powder selecting machine and collecting and storing fine gravel powder; and S4, acquiring flowability, feeding the powder through a discharging valve, lifting the powder to a sand-making tower through a belt conveyor and a belt-bucket elevator, processing the gravels or aggregate chips through a sand-making shaping machine, an air jet sieve and a moisture mixing machine from top to bottom, and discharging the mixture to obtain finished product machine-made sand. High performance concrete and high strength concrete are prepared favorably, and a lot of water sources are not consumed.

Owner:徐州金盟新型建材有限公司

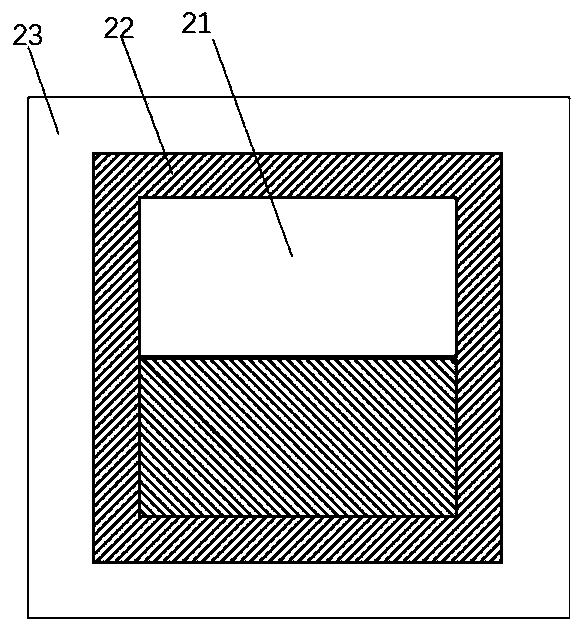

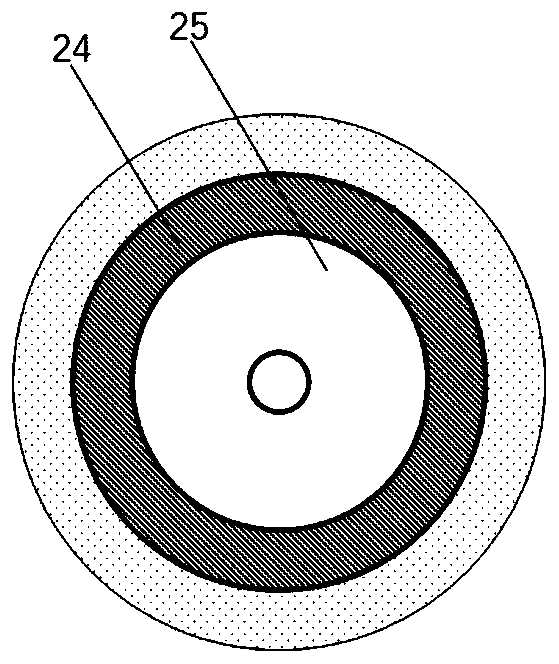

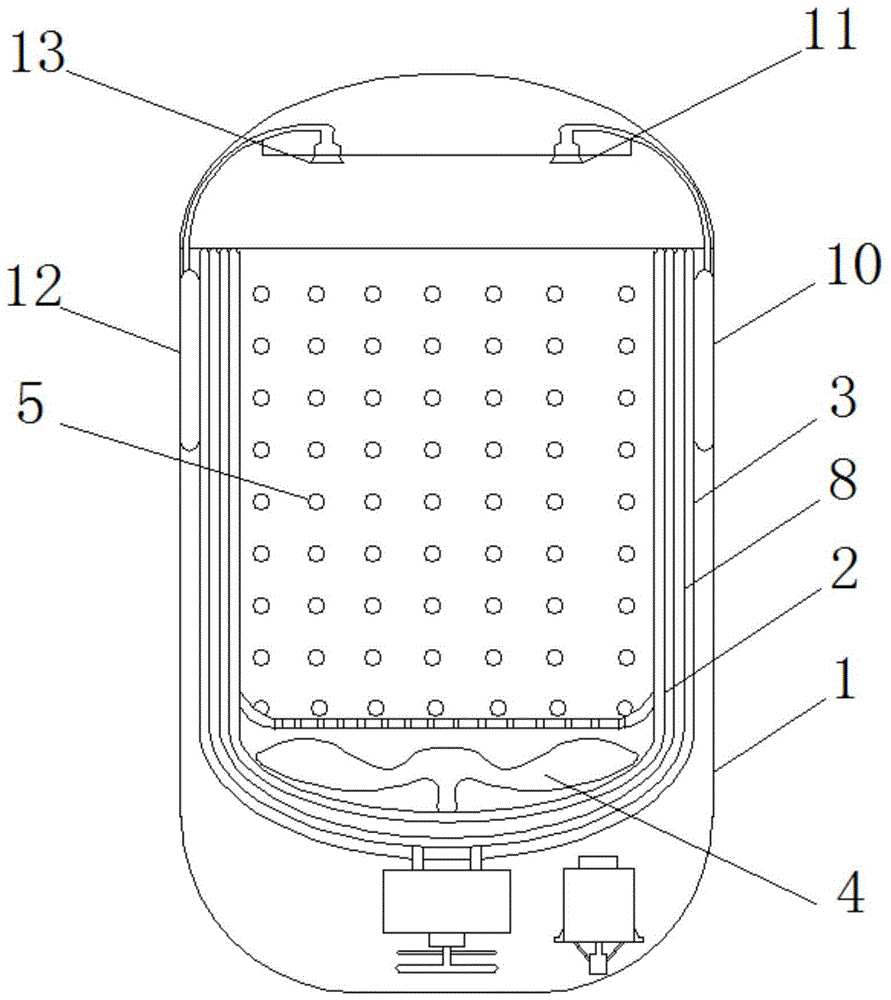

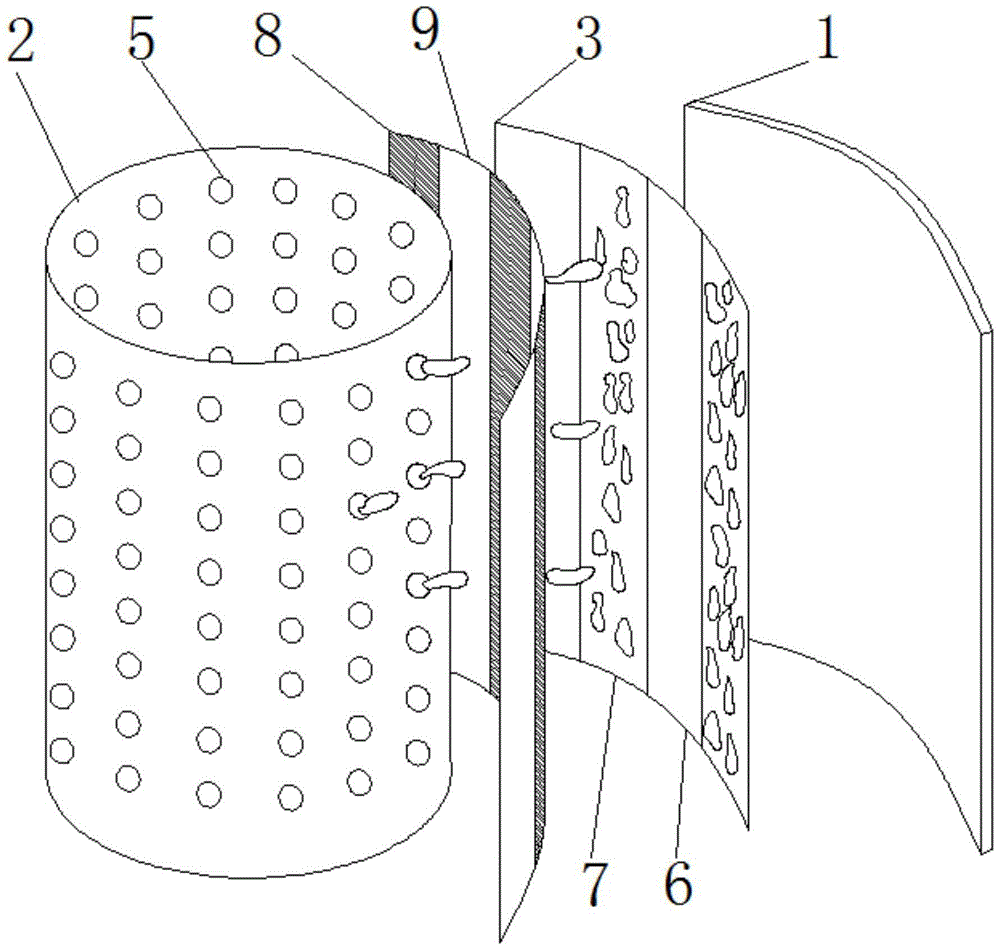

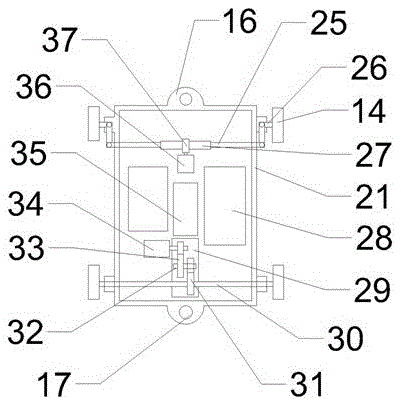

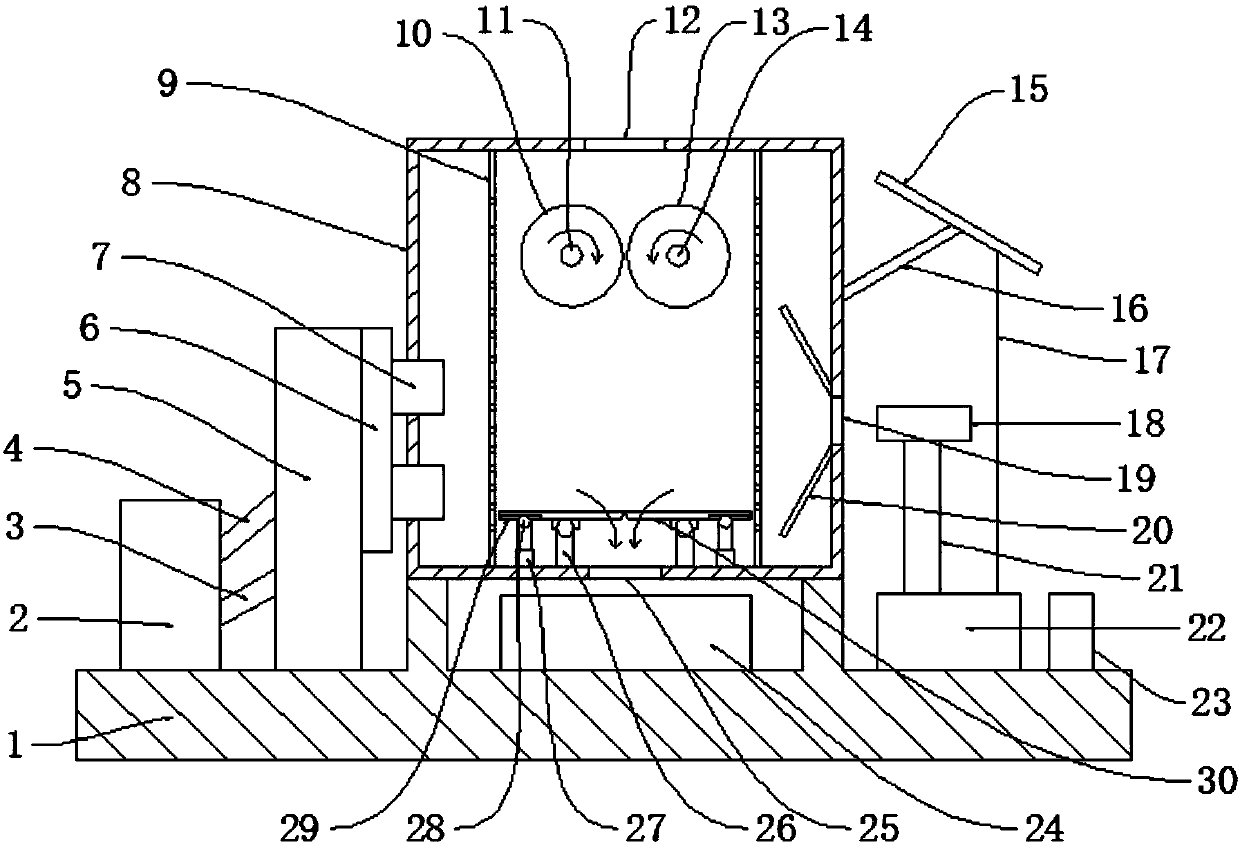

A waterless washing machine

ActiveCN105063960BNo need to consume water resourcesReduce energy consumptionOther washing machinesTextiles and paperPulp and paper industryEnergy consumption

The invention provides a waterless washing machine. The washing machine comprises a washing machine housing body, a rotary inner cylinder, a dirt removing outer cylinder, a blower and a washing agent adding device. The rotary inner cylinder is used for stirring clothes. The dirt removing outer cylinder is used for sucking grease and dust on the clothes. The blower is used for inputting upward flowing air in the rotary inner cylinder. The dirt removing outer cylinder and the blower are arranged in the washing machine housing body. The washing agent adding device is arranged in the washing machine housing body and is communicated with the rotary inner cylinder. Through holes are arranged in the side wall and the bottom plane of the rotary inner cylinder. A dust sucking part used for sucking fat sucking part of grease and generating static electricity is arranged on the side wall of the dirt removing outer cylinder. According to the invention, by use of the static dust removing technology and centrifugal treatment processing technology, clothes can be cleaned without water, so energy consumption and pollution are reduced.

Owner:徐州飞云泡沫制品有限责任公司

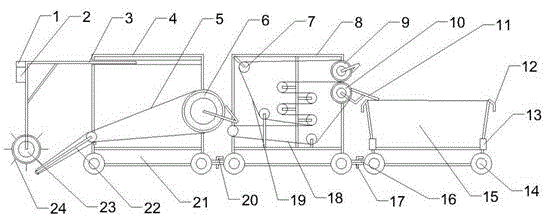

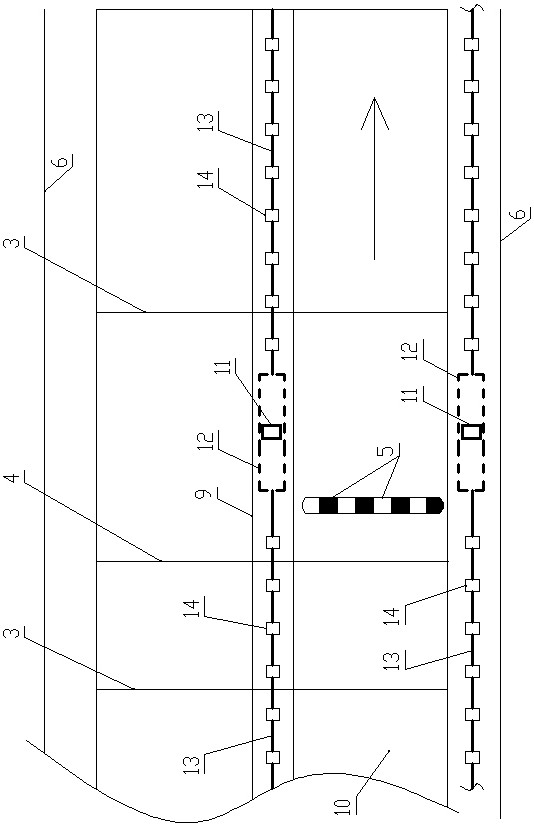

Combined remote control sewer desilting vehicle

The invention discloses a combined remote control sewer desilting vehicle which comprises frames, a first framework and a second framework. A driven shaft is installed on the front portion of each frame, wherein a wheel is installed at one end of the driven shaft; a driving shaft is installed on the back portion of each frame, wherein wheels are installed at the two ends of the driving shaft; batteries are installed in the two sides of each frame; a control module is installed in the middle of each frame; a telescopic rod is installed at the top of the first framework, and a silt sweeping motor is installed at the bottom end of the telescopic rod and sleeved with a silt sweeping brush; the first framework is provided with a conveyor belt, a conveying motor is installed in the conveyor belt, and a silt scraping plate is installed at the tail end of the conveyor belt; multiple rollers are installed in the second framework, a first pressure filtration motor and a second pressure filtration motor are installed on the upper portion of the tail end of the second framework, the outer surface of the first pressure filtration motor is sleeved with a first pressure filtration belt, and the outer surface of the second pressure filtration motor is sleeved with a second pressure filtration belt; a silt collecting bucket is installed at the tail of the desilting vehicle. According to the combined remote control sewer desilting vehicle, the efficiency is high, a large amount of manpower is saved, and the labor intensity of workers is lowered.

Owner:刘瑞

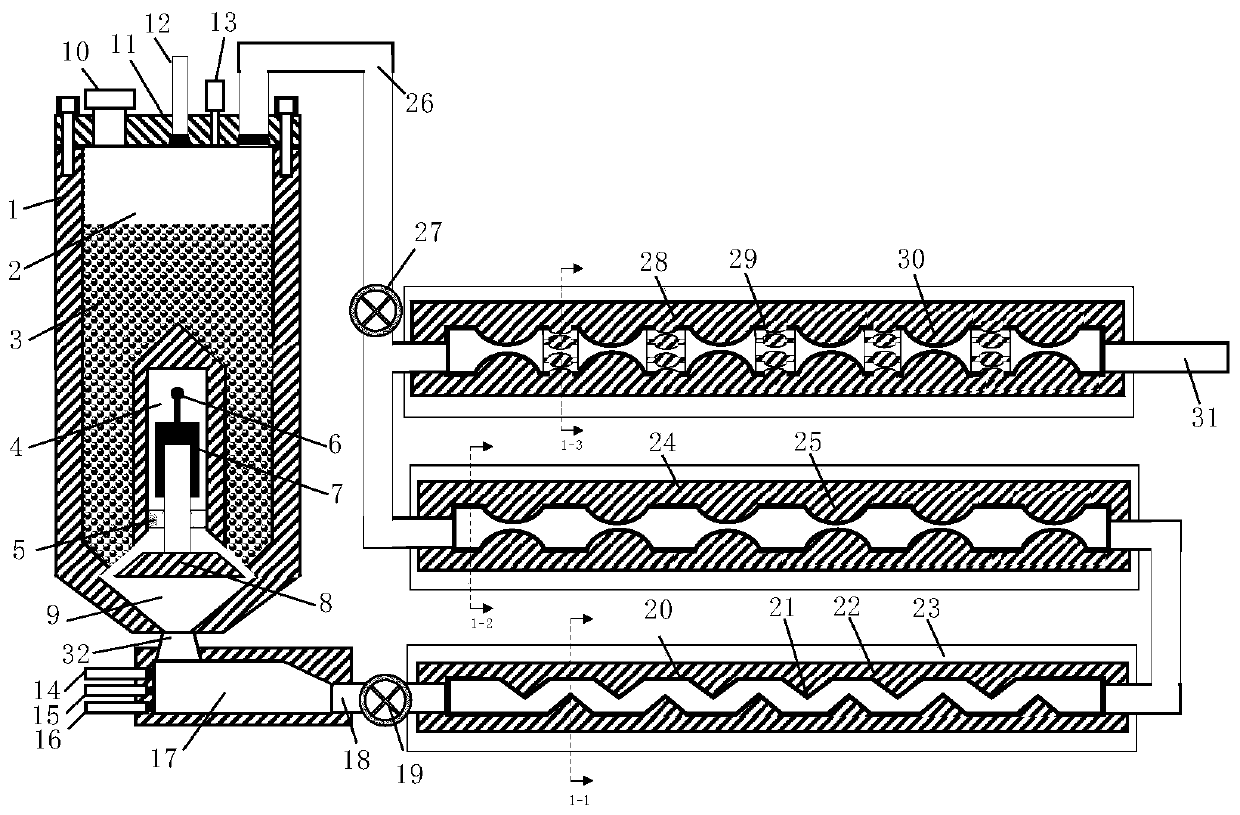

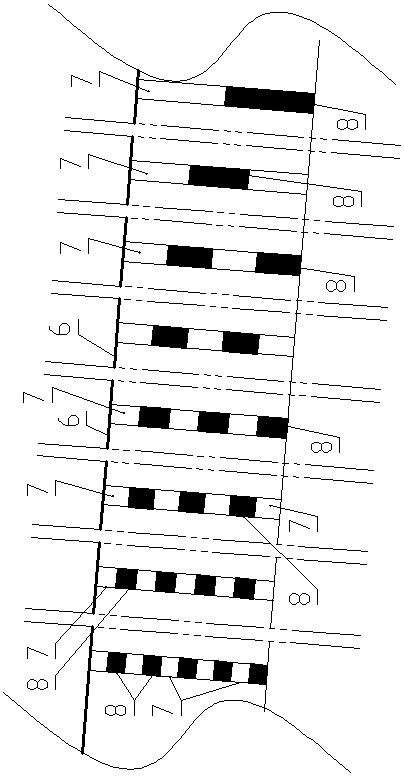

Dry paper making device and method

InactiveCN105648827AFine surfaceWide range of applicationsPaper-making machinesRaw material divisionPapermakingFineness

The invention discloses a dry papermaking device which comprises a material preparation device, a forming device, a transferring net, a compacting roller and a drying box, wherein the material preparation device, the forming device, the transferring net, the compacting roller and the drying box are connected in sequence; the forming device comprises a pulp distributor, a pulp flow box and a vacuum net cage; the pulp distributor comprises a pulp distributor body, a Venturi pipeline and a pulp distributor inlet pipe; the material preparation device is connected with the lower end of the pulp distributor body through the pulp distributor inlet pipe and the Venturi pipeline; the upper end of the pulp distributor body is connected with one end of the pulp flow box; the other end of the pulp flow box is arranged on the outer side of an inlet of the vacuum net cage; the outlet end of the vacuum net cage is connected with the transferring net; the vacuum net cage is driven by a variable-speed motor. The dry papermaking method based on the equipment comprises the following steps: material preparation, forming, transferring, compacting, drying and coiling; made paper has the advantages of surface fineness, softness, comfortableness and zero linting and dusting; furthermore, no glue is applied in the papermaking process, so that a large amount of water resources can be saved; therefore, the dry papermaking device and the dry papermaking method are environment-friendly and energy-saving.

Owner:韦周全

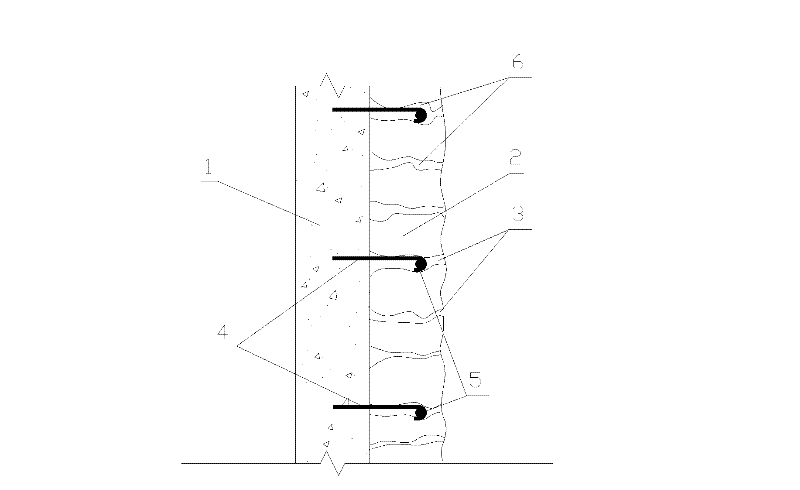

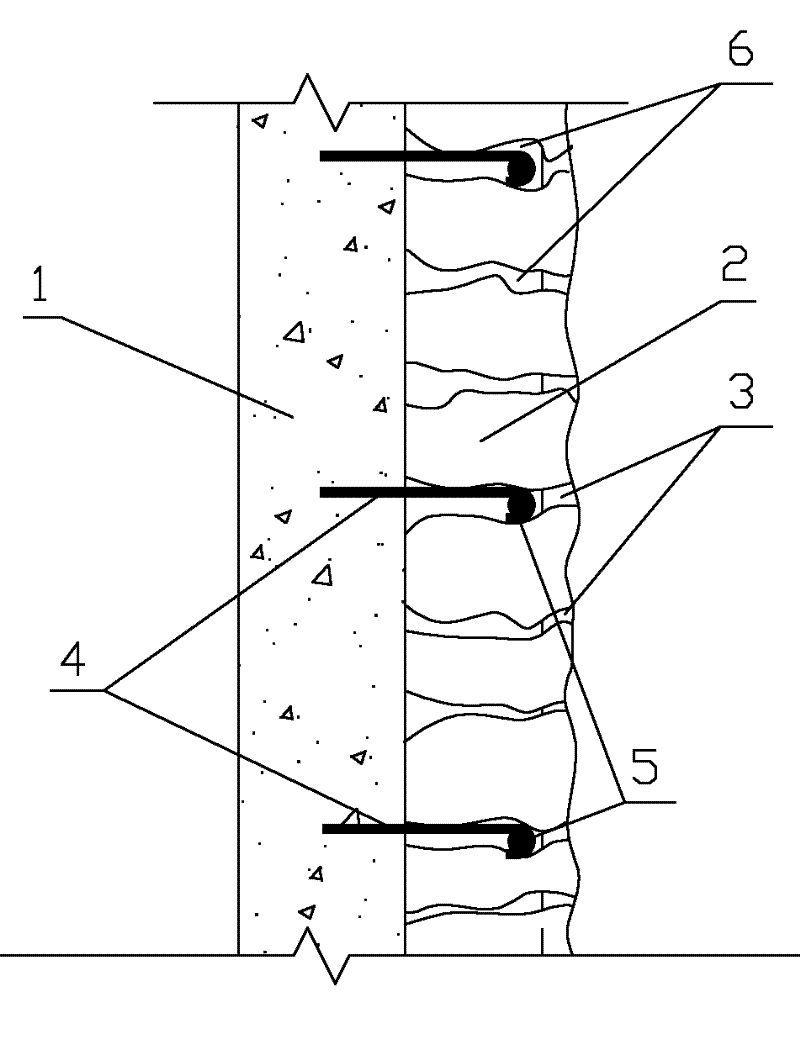

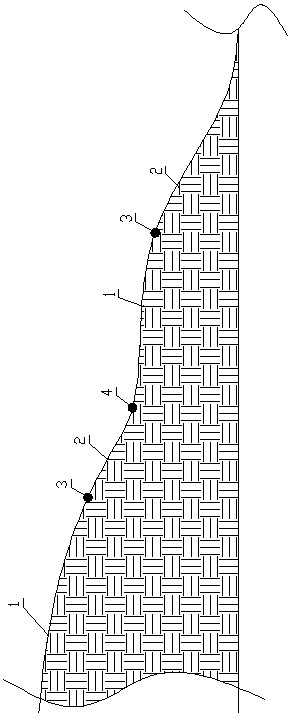

Pulling structure of natural rock block fake-dry-masonry decorating wall and manufacturing method

Disclosed are a pulling structure of a natural rock block fake-dry-masonry decorating wall and a manufacturing method. The pulling structure of the natural rock block fake-dry-masonry decorating wall comprises a plurality of rows of reinforcing steel bar drag hooks perpendicular to a wall body, flat-head ends of the reinforcing steel bar drag hooks are fixed with the wall body, drag hook ends of the reinforcing steel bar drag hooks are exposed out of the wall body, each row of reinforcing steel bar drag hooks are connected via a horizontal pulling bar, the horizontal pulling bars are placed in the drag hook ends of the reinforcing steel bar drag hooks, and cement bed mortar, the reinforcing steel bar drag hooks and the horizontal pulling bars are solidified integrally to form an inner pulling structure of a rock block wall. The natural rock block fake-dry-masonry decorating wall has the advantages that stones of the natural rock block fake-dry-masonry decorating wall are natural, seams are intriguing, and art culture of the decorating wall is unique. In addition, the pulling structure of the natural rock block fake-dry-masonry decorating wall has a good decorating effect, meets needs of modern life, and has fine application prospect in the field of engineering construction along with improvement of living standards of people.

Owner:ZHEJIANG HAITIAN CONSTR GROUP

Machine-made sand and application thereof

InactiveCN110590196ANo need to consume water resourcesSimple processSolid waste managementSlagQuenching

The invention particularly relates to machine-made sand and an application thereof, and belongs to the fields of building material processing technology and environmental protection. The machine-madesand is prepared through the following steps: step 1, after high-temperature liquid ferronickel slag melt is discharged from a slag opening of a furnace, slow cooling air quenching cooling is carriedout on the high-temperature liquid ferronickel slag melt, and ferronickel slag is obtained; and during slow cold air quenching cooling, the cooling speed is controlled to be smaller than or equal to 70 DEG C / s; step 2, the ferronickel slag is placed in a jaw crusher and is subjected to primary crushing; and step 3, the ferronickel slag obtained in the step 2 is placed in an efficient fine crusherand is subjected to fine crushing, so that the ferronickel slag machine-made sand is obtained. After optimization, the measurement result of the crushing index value of the obtained machine-made sandis 6.8-7%. The machine-made sand provided by the invention is mixed with natural sand to be used as a building material. By means of a series of treatment, especially air cooling treatment at a reasonable speed, on the ferronickel slag, the ferronickel slag has excellent performance, and necessary conditions are provided for replacing a part of concrete fine aggregate and changing waste into valuable resources for cyclic utilization.

Owner:CENT SOUTH UNIV

A high-efficiency powder removal and separation device for machine-made sand for construction

InactiveCN104249058BEfficient separationNo need to consume water resourcesGas current separationWorking environmentEngineering

The invention discloses a high-efficiency powder removal and separation device for machine-made sand used in construction. The feeding channel between the bulk material tray and the sand collecting hopper. The shell is also provided with a finished sand sand outlet channel connected to the bottom of the sand collecting hopper. A sorting device is installed on the top of the shell. There is a bag filter and a fan, the inlet of the bag filter is connected to the air outlet of the sorting device through the first pipeline, and the air inlet of the fan is connected to the air outlet of the bag filter through the second pipeline. At the outlet, there is a mud and sand collection point on the bag filter. The high-efficiency powder removal and separation device for machine-made sand for construction of the present invention does not need to consume water resources, has low energy consumption, no dust pollution, no screen wear, high separation efficiency, and greatly improves the working environment.

Owner:襄阳宇清重工装备有限公司

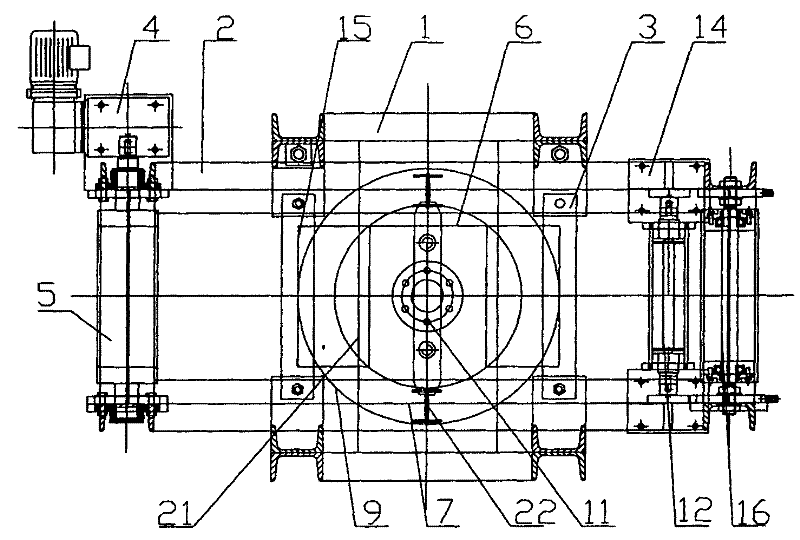

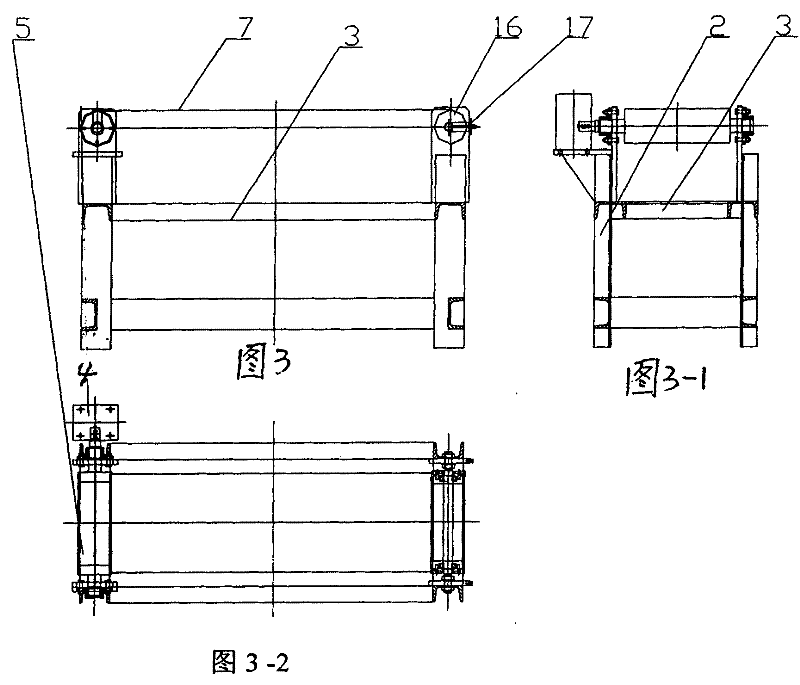

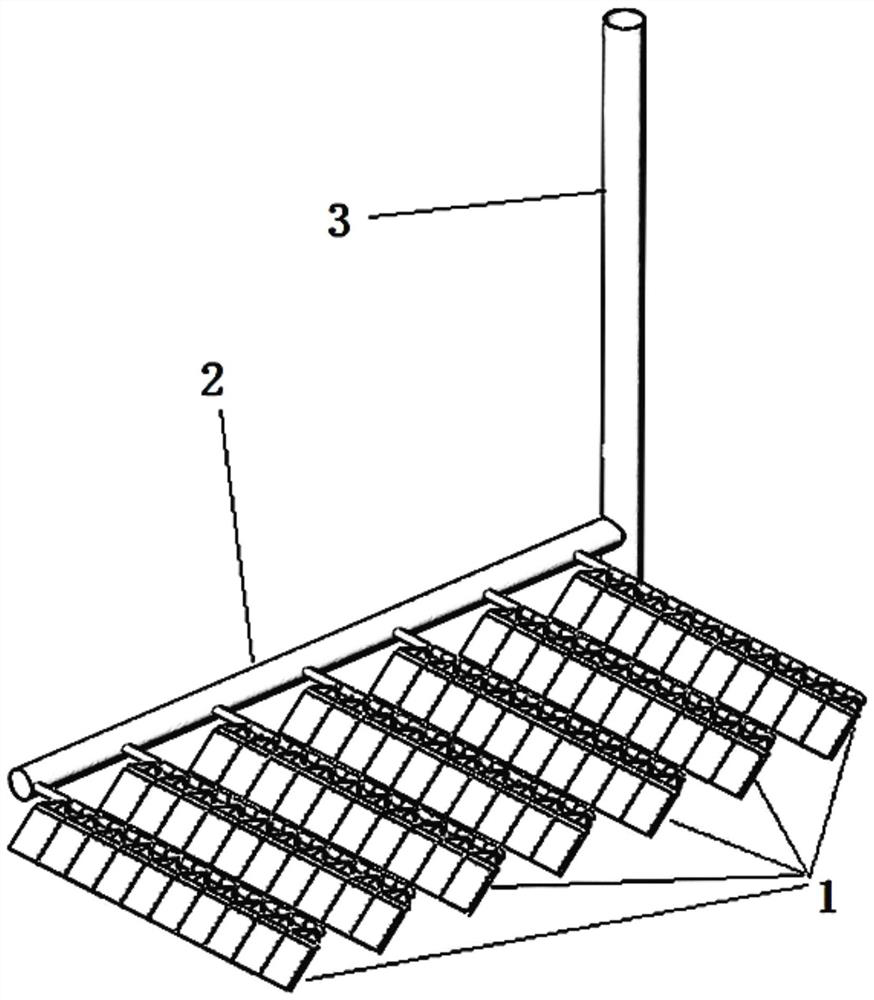

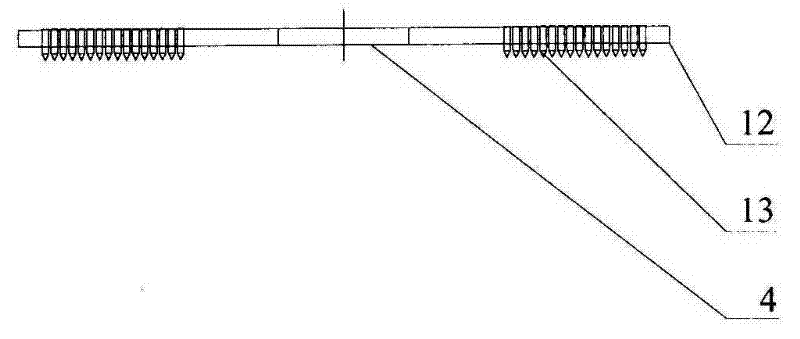

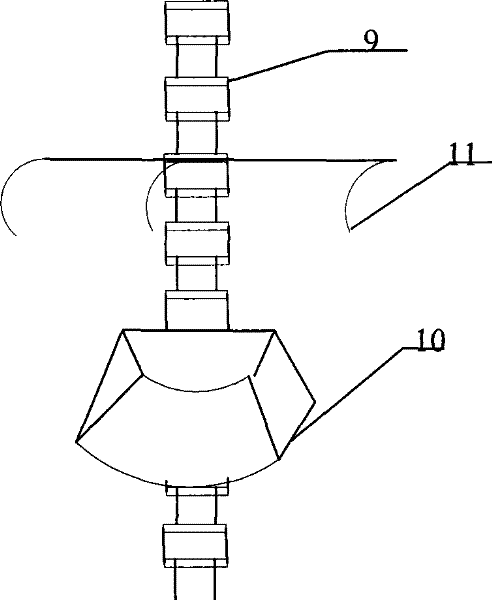

Rotary disc type high-gradient permanent magnetic separator

InactiveCN101912817BNo need to consume water resourcesComply with the guidelines and policies of energy saving and emission reductionMagnetic separationCircular discMagnetic separator

The invention discloses a rotary disc type high-gradient permanent magnetic separator, which comprises a transmission roller fixing frame, a driving roller and a driven roller that are arranged at two ends of the transmission roller fixing frame and a conveyer belt that is driven by the driving roller and the driven roller; the middle of the transmission roller fixing frame is provided with a main body stander; the main body stander consists of a lower base frame body which is fixed and connected with the transmission roller fixing frame and a permanent magnetic steel group supporting standerwhich is arranged above the lower base frame body through a vertical displacement regulating part; a permanent magnetic steep group and a rotary disc which is driven by a power source and can do horizontal rotary motion are sequentially arranged on the permanent magnetic steel group supporting stander from bottom to top, the permanent magnetic steel group is arranged between an upper layer and a lower layer of the conveyer belt, and the rotary disc is arranged above the upper layer of the conveyer belt; an auxiliary magnetic pole of a ring structure is arranged on the surface of the rotary disc; and an air-lock feeder is arranged right above one end of the conveyer belt, and a magnetic material receiving hopper is arranged under the conveyer belt through a receiving hopper supporting frame.

Owner:HENAN POLYTECHNIC UNIV

Technology for chromatographic extraction of glutamic acid after centrifugal thallus removal

InactiveCN110551039AReduce processing difficultyReduce sodium hydroxideOrganic compound preparationAmino-carboxyl compound preparationChromatographic separationFiltration

The invention belongs to the technical field of amino acid separation and purification, and discloses a process for chromatographic extraction of glutamic acid after centrifugal thallus removal, whichcomprises the following steps: step 1) filtration and sterilization, step 2) chromatographic separation, step 3) resin column adsorption, and step 4) concentration and crystallization. The method hasthe advantages of low wastewater yield, low environmental pressure and higher glutamic acid yield, and has favorable industrial practical value.

Owner:卢松

Safe long and large downhill road section and vehicle cooling method

ActiveCN111827026AImprove protectionNo need to consume water resourcesDomestic cooling apparatusLighting and heating apparatusSpeed bumpEngineering

The invention discloses a safe long and large downhill road section which comprises an upward convex road section and a common road section alternately arranged. The common road section is a linear road section or a downward concave road section; a deceleration strip-shaped road surface coating is arranged on the downhill road surface in front of the inflection boundary of the rapid and slow roadsection; a handrail is arranged on the right side in front of therapid and slow road sectioninflection boundary; the handrail comprises a cross bar, the cross rod is supported on the ground through aplurality of vertical rods; first color layers and second color layers are alternately arranged on the side walls of the vertical rods in the vertical direction, the first color layers and the secondcolor layers are formed by spraying pigments of different colors, and the total number of the first color layers and the second color layers on each set of vertical rods is sequentially reduced from back to front till the total number of the first color layers and the second color layers on each vertical rod is reduced to two. The invention provides an air injection system for cooling the vehiclebrake. The invention further discloses a corresponding vehicle cooling method. The driving safety can be improved through air injection cooling and active utilization of the visual effect, water resources are not consumed, and environmental protection is facilitated.

Owner:ZHENGZHOU COMM PLANNING SURVEY & DESIGN INST

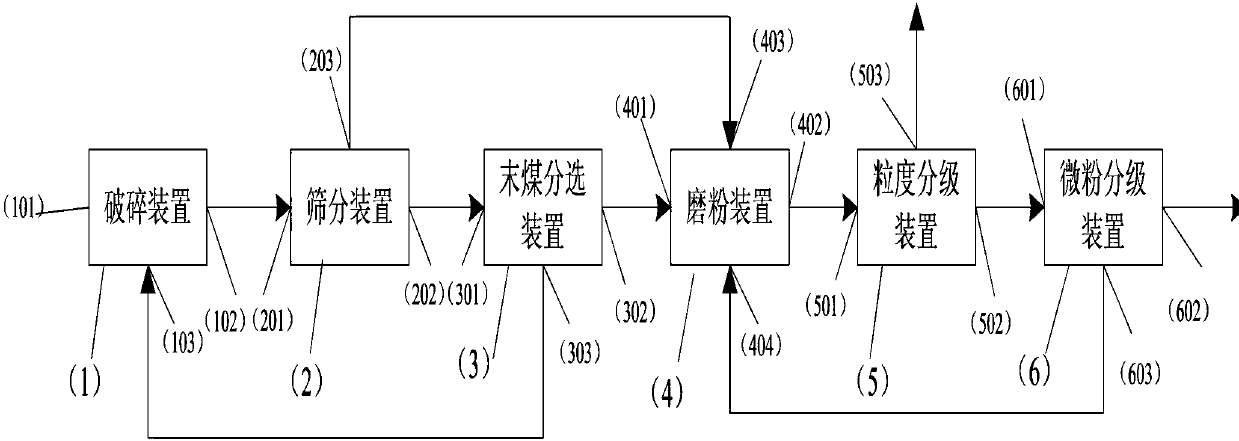

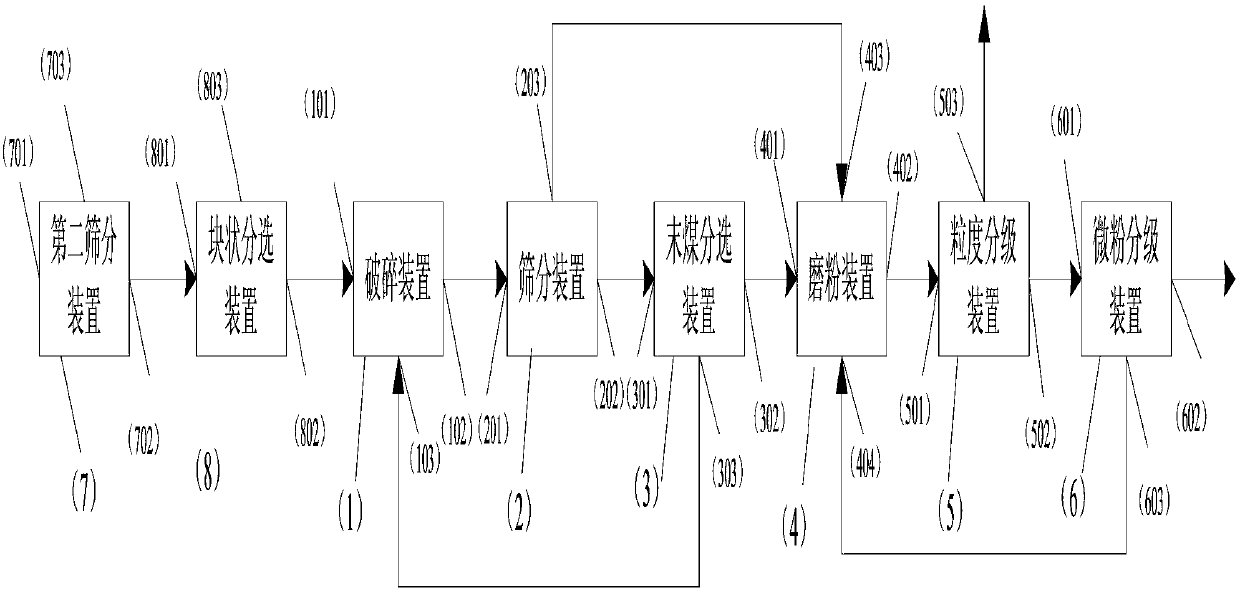

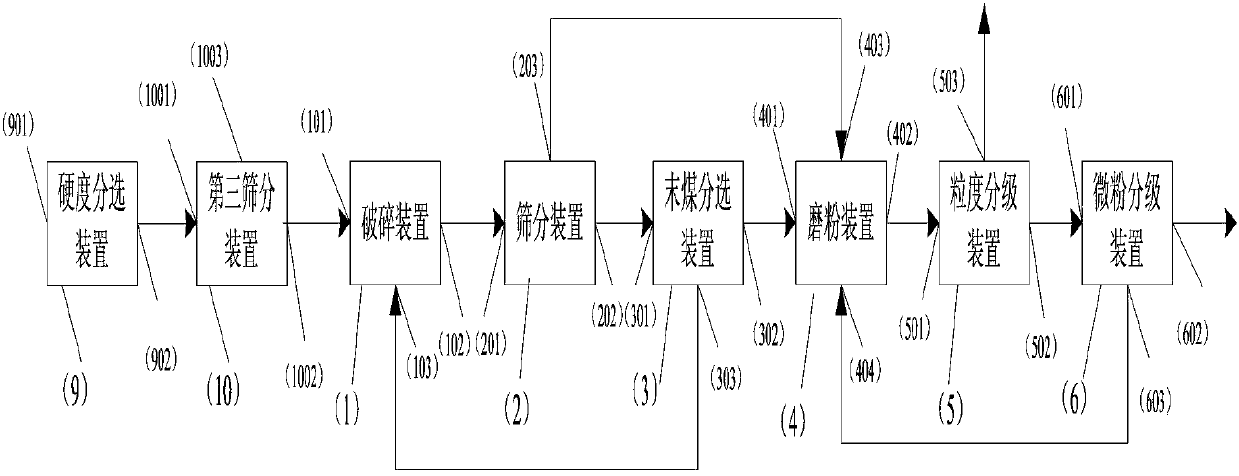

Coal dry-process grading upgrading integrated system and processing method thereof

The invention provides a coal dry-process grading upgrading integrated system and a processing method thereof. The coal dry-process grading upgrading integrated system comprises a crushing device, a first inlet end of the crushing device, an outlet end of the crushing device, a second inlet end of the crushing device, a first inlet end of a screening device, a first outlet end of the screening device, a second outlet end of the screening device, a fine coal sorting device, a first inlet end of the fine coal sorting device, a first outlet end of the fine coal sorting device, a first inlet end of the fine coal sorting device, a grinding device, a first inlet end of the grinding device, a first outlet end of the grinding device, a second inlet end of the grinding device, a third inlet end ofthe grinding device, a granularity grading device, an inlet end of the granularity grading device, a first outlet end of the granularity grading device, a second outlet end of the granularity gradingdevice, a micro powder grading device, an inlet end of the micro powder grading device, a first outlet end of the micro powder grading device and a second outlet end of the micro powder grading device.

Owner:兖矿科技有限公司 +1

Photovoltaic panel cluster cooling system

PendingCN112187173AImprove heat transfer efficiencyImprove suction effectPhotovoltaicsPhotovoltaic energy generationCold airThermodynamics

The invention discloses a photovoltaic panel cluster cooling system. A solar photovoltaic panel assembly comprises a cooling air channel plate, a solar photovoltaic panel body, cooling fins and cold air transition connecting pipes; the cooling air channel plate is buckled on the back surface of the solar photovoltaic panel body; the radiating fins are positioned between the cooling air channel plate and the solar photovoltaic panel bod; heat exchange channels are formed among the adjacent radiating fins, the cooling air channel plate and the solar photovoltaic panel body; each heat exchange channel is communicated with one end of the corresponding cold air transition connecting pipe; the other end of each cold air transition connecting pipe in the solar photovoltaic panel assembly is communicated with a corresponding second communicating pipe; the second communicating pipes in heat exchange module are connected with first communicating pipes; the first communicating pipes are connectedwith the bottom of a chimney; and the chimney is vertically distributed. The system has the advantages of being free of water resource consumption, good in economical efficiency and high in heat exchange efficiency.

Owner:XIAN THERMAL POWER RES INST CO LTD

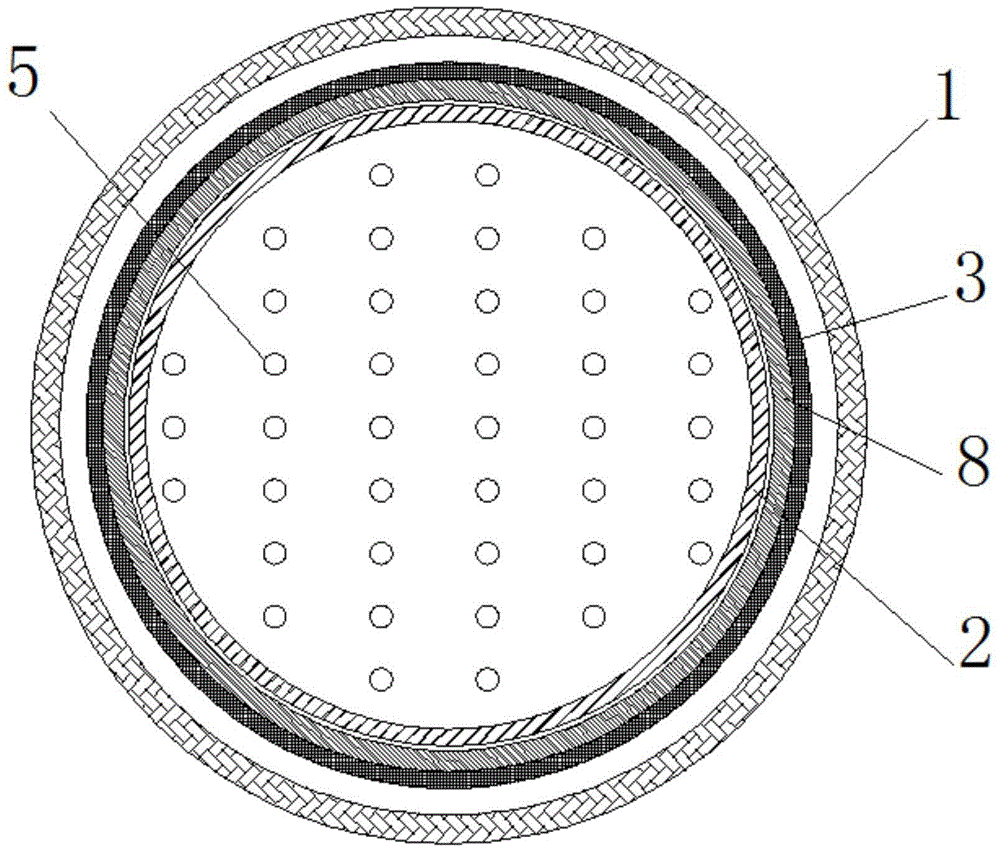

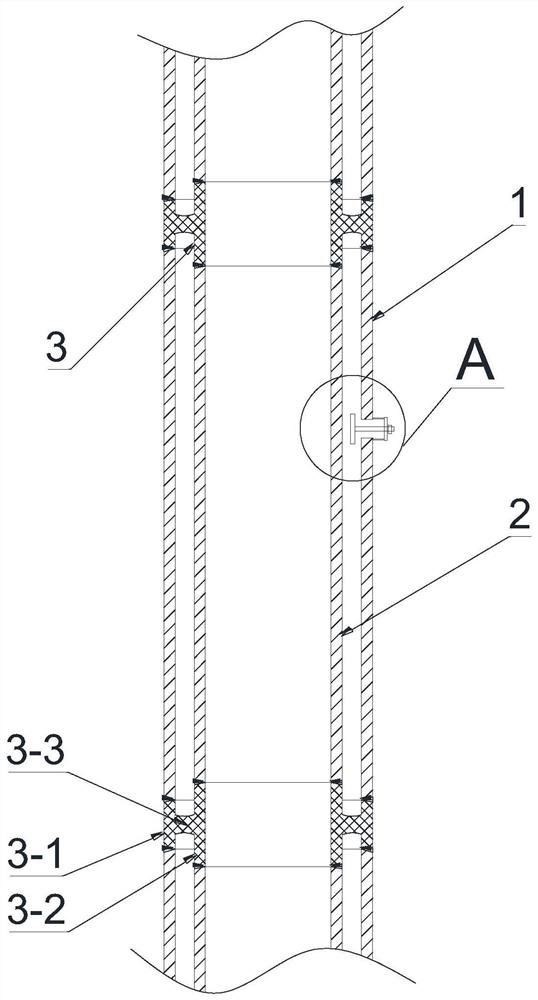

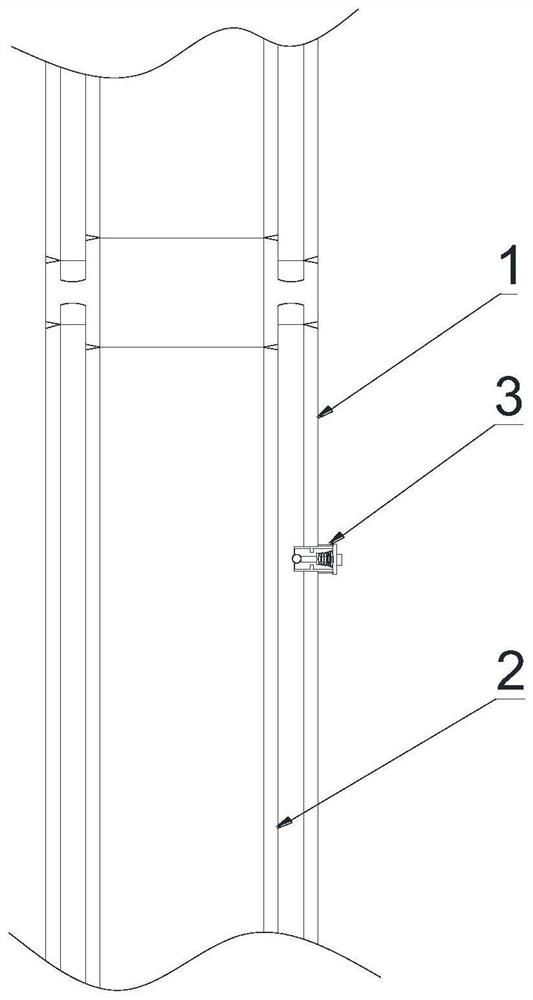

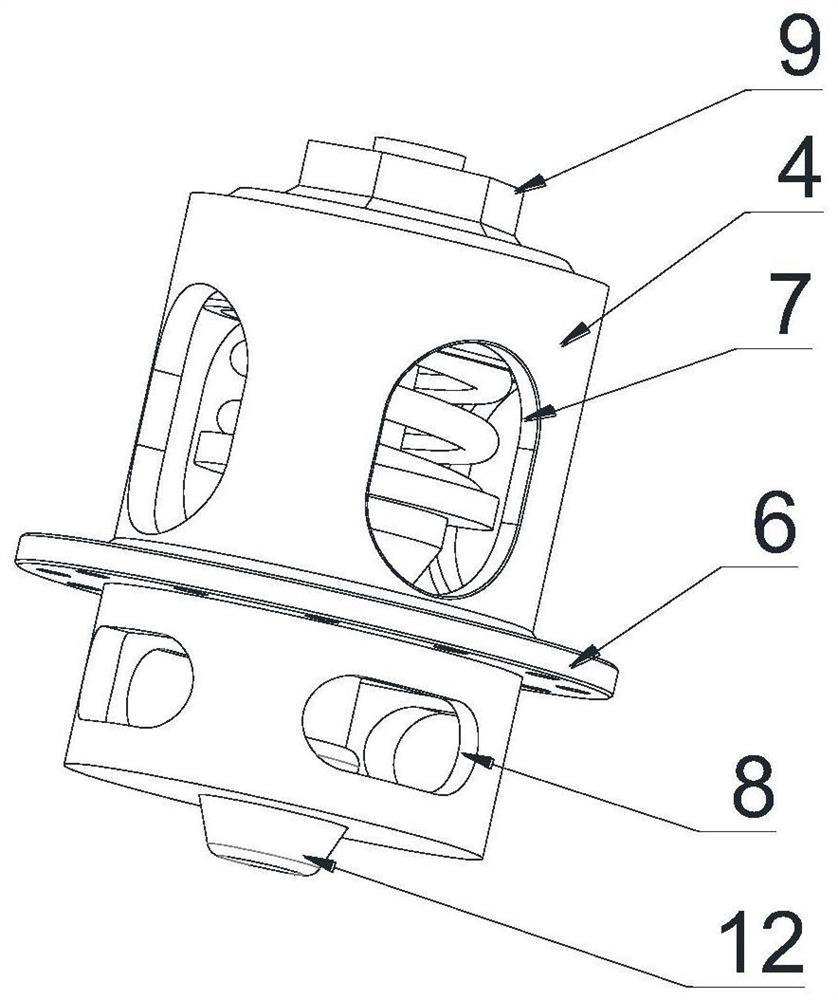

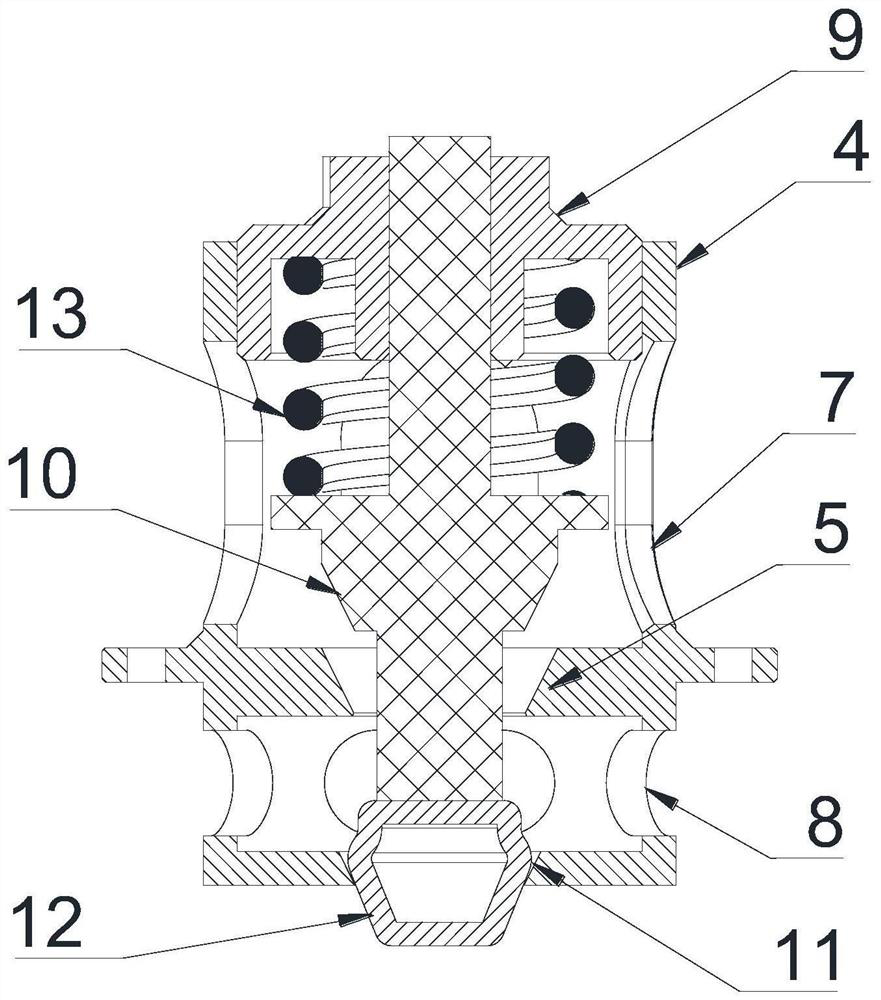

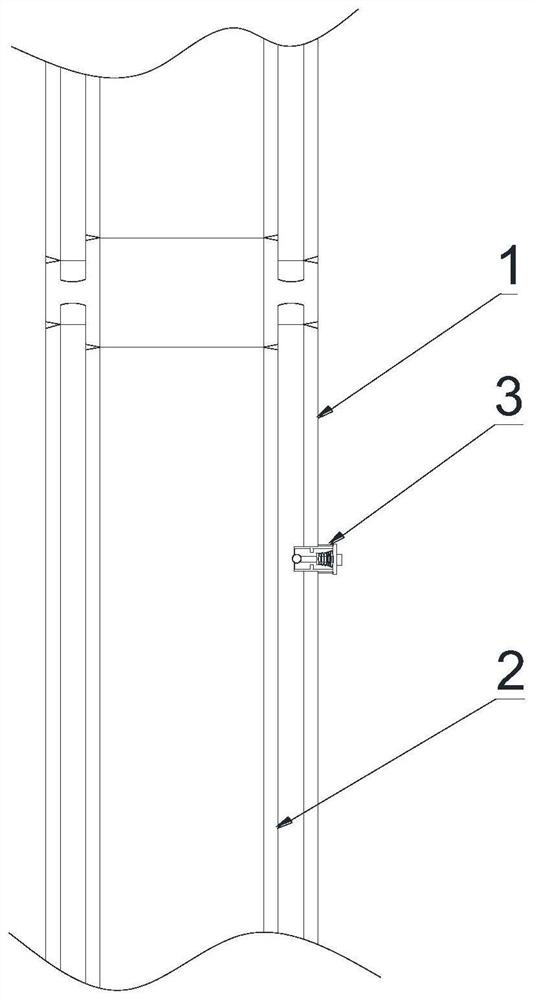

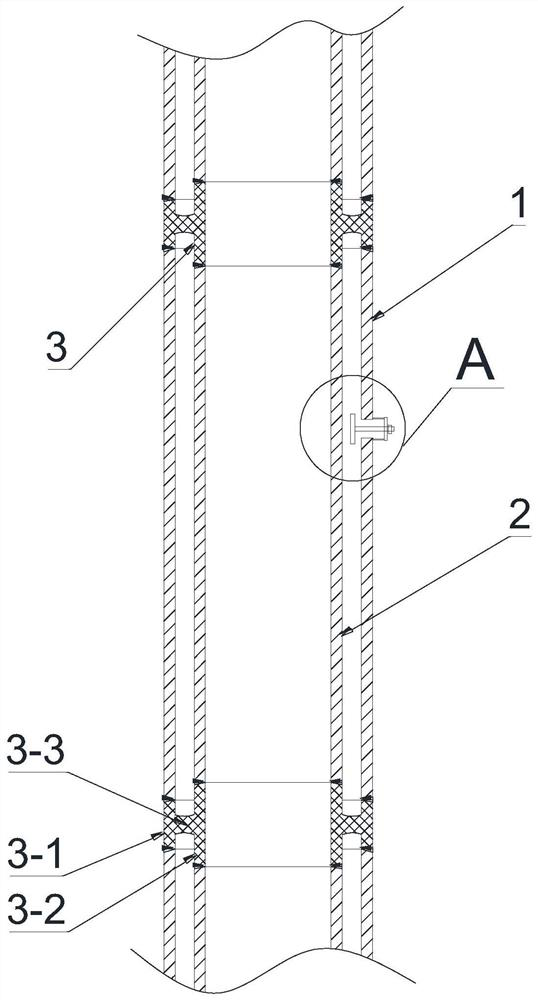

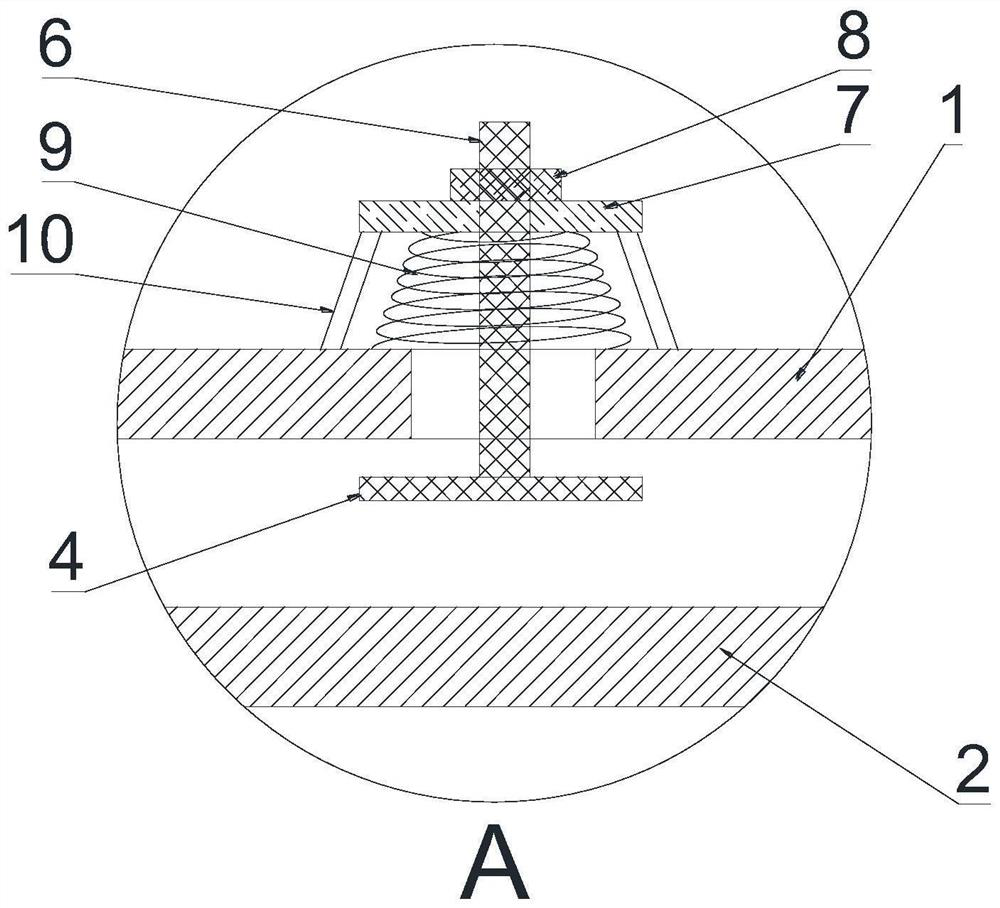

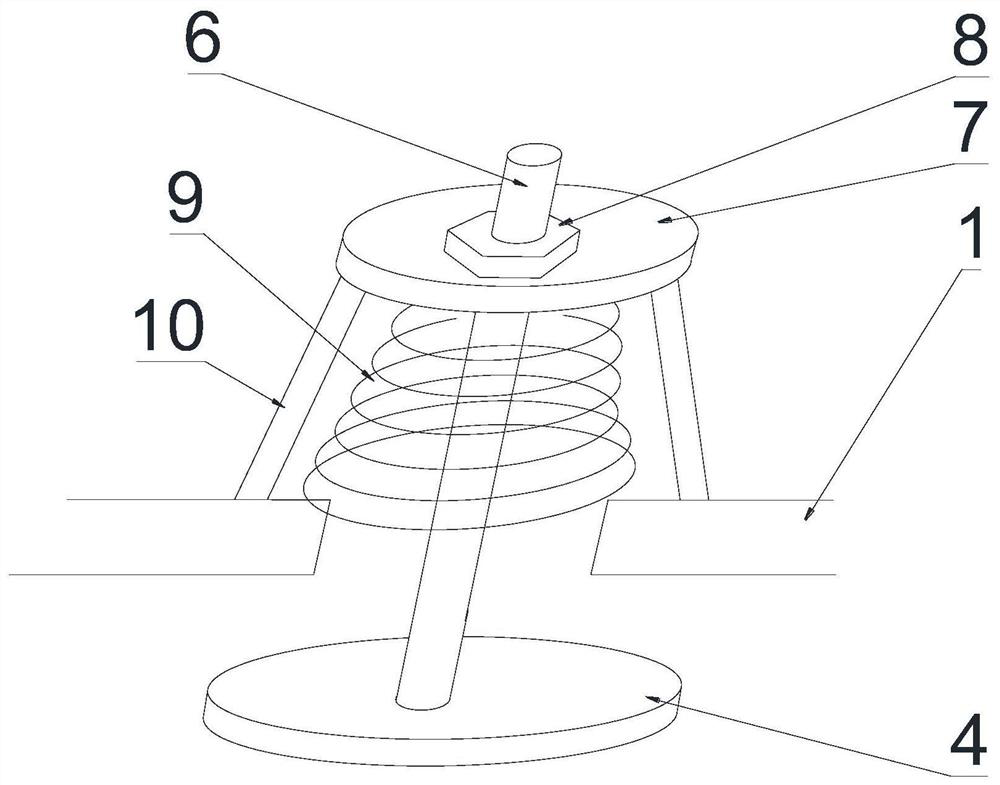

A pressure-resistant double-layer conveying pipeline

ActiveCN112161121BReduce weightReduce manufacturing costEqualizing valvesPipe elementsMechanical engineeringSeawater

The purpose of the present invention is to provide a pressure-resistant double-layer conveying pipeline, which is directly filled with seawater during the installation and sinking into the seabed, which reduces the total weight during transportation and hoisting, and reduces the direct cost during the production process. Process and cost increase due to filling with liquid; including an inner tube, an outer tube, and a flexure stop device, the inner tube is spliced from a plurality of inner tube segments, the outer tube is spliced from a plurality of outer tube segments, and the flexure stop device It includes an outer pipe connection ring, an inner pipe connection ring and a support body. The outer pipe is also provided with an automatic water injection valve. In the annular space between, in order to reduce the influence of seawater static pressure on the pipeline pressure.

Owner:东营新达德安新材料科技有限责任公司

A way to restore dry rivers

Owner:青岛环境工程设计院有限公司

Safe long downhill section and vehicle cooling method

ActiveCN111827026BImprove protectionNo need to consume water resourcesDomestic cooling apparatusLighting and heating apparatusSpeed bumpEngineering

The invention discloses a safe long and downhill road section, which includes alternately arranged up-convex road sections and ordinary road sections, the ordinary road section is a straight road section or a concave road section; pavement coating; railings are provided on the right side of the road section in front of the turning boundary of the steep and slow road sections, and the railings include horizontal bars, which are supported on the ground by several vertical bars. The second color layer, the first color layer and the second color layer are formed by spraying paints of different colors. The total number of first and second color layers on the rod is reduced to two. The invention is provided with an air injection system for cooling the brakes of the vehicle. The invention also discloses a corresponding vehicle cooling method. The invention can improve driving safety through air jet cooling and active use of visual effects, does not consume water resources, and is beneficial to environmental protection.

Owner:ZHENGZHOU COMM PLANNING SURVEY & DESIGN INST

A kind of pipeline water injection valve and the seabed transportation pipeline using it

ActiveCN112161142BStable pressureReduce weightEqualizing valvesPipe elementsPipe waterAmbient pressure

The object of the present invention is to provide a pipeline water injection valve and a seabed conveying pipeline using it, which is directly filled with seawater during the installation process of sinking into the seabed, which reduces the total weight in the process of transportation and hoisting, and at the same time reduces the The process and cost increase caused by direct filling of liquid in the production process; including the outer tube and the inner tube, the anti-bending structures are arranged at intervals along the length direction of the inner and outer tubes, and a plurality of installation holes are opened on the outer tube, and the installation holes A pipeline water injection valve is fixed inside, and the pipeline water injection valve is used to inject liquid into the annular space between the inner pipe and the outer pipe, and controls the pipeline water injection valve to stop water injection when the external environmental pressure is greater than the design pressure, and closes the outer pipe water inlet.

Owner:SHANDONG ZHONGLI HIGH PRESSURE VALVE CO LTD

Permanent magnetic high-gradient comprehensive force field separator with disc structure

InactiveCN101947492BNo need to consume water resourcesComply with the guidelines and policies of energy saving and emission reductionHigh gradient magnetic separatorsCircular discDrive shaft

The invention relates to a permanent magnetic high-gradient comprehensive force field separator with a disc structure, which comprises a support, a supporting substrate, a plurality of damping springs, a magnetic disc, a magnetism gathering nail rotating disc, a top layer circular ring disc, a guide shaft sleeve and a transmission shaft, wherein the supporting substrate is in a circular ring-shaped structure and arranged on the support, the plurality of the damping springs are arranged by surrounding the circumference of the supporting substrate, the magnetic disc is mounted above the supporting substrate, the magnetism gathering nail rotating disc and the top layer circular ring disc are sequentially mounted above the magnetic disc by clearance fit, the guide shaft sleeve is mounted below the magnetism gathering nail rotating disc, extends in a vertical downward manner and penetrates the central position of the magnetic disc, the transmission shaft supports a central hole of the supporting substrate, and the lower end of the transmission shaft is combined with a driving mechanism; the top layer circular ring disc is combined with the magnetic disc thorough a connecting part arranged by surrounding the periphery of the top layer circular ring disc, and the bottom surface of the magnetic disc is combined with a vibrating motor arranged below the supporting substrate through theconnecting part; a feeding device is arranged on one side above the top layer circular ring disc; and a non-magnetic material receiving device is mounted below the magnetic disc, and the mounting position of the non-magnetic material receiving device is in upper-lower corresponding with the mounting position of the feeding device.

Owner:HENAN POLYTECHNIC UNIV

Crushing machine

PendingCN107812559ANo need to consume water resourcesBlow away avoidGrain treatmentsEngineeringMachine

The invention discloses a crushing machine which comprises a machine frame. The machine frame is provided with a machine box. The machine box is composed of a top plate, a bottom plate and four side plates. The top plate is provided with a feeding inlet, and crushing couple rollers are arranged under the feeding inlet. A material receiving device is arranged under the crushing couple rollers and comprises two material receiving plates which are located on the same horizontal plane and further make contact with each other. The lower surfaces of the material receiving plates are connected with supporting rods in a rotating mode. The lower surfaces of the material receiving plates are further provided with sliding chutes, and the sliding chutes are internally connected with rollers in a rolling mode. The rollers are connected with air cylinders in a rotating mode. The supporting rods and the air cylinders are both fixed to the bottom plate. A discharging outlet is formed in the bottom plate and located under the contact position of the two material receiving plates. Air blowing holes are formed in one side plate and located between the crushing couple rollers and the material receiving plates. The air blowing holes are connected with a draught fan, and the draught fan is provided with a cooler. An air outlet hole is formed in the side plate opposite to the air blowing holes. The machine frame is further provided with a wind power generation device. According to the scheme, cold-air blast is used for cooling corundum, and no water resource needs to be consumed.

Owner:遵义兴正业矿业有限公司

Sewage conduit cleaning device

The invention discloses a sewage conduit cleaning plant, principally applied in municipal sewage conduit clean-up work. The inventive technical scheme includes a host computer, an accessory machine, a chain, a chain sprocket, a floor support frame supporting the chain, a ground support frame supporting the chain at the conduit manhole and conduit port, and an accessory machine supporting the ground support frame, wherein, the host computer includes a gearshift case, a transmission mechanism, and a host computer subbase supporting the gearshift case, the transmission mechanism and the ground support frame; the output shaft of the gearshift case is connected with the driving shaft of the chain through the transmission mechanism; and a bucket for digging and loading conduit sundries is disposed on the chain. The invention has advantages of reduced labourer work intensity, high labor efficiency, high sewage conduit cleaning-up quality, simple producing and use, and low cost.

Owner:孟祥德 +1

Pipeline water injection valves and seabed conveying pipeline applying same

ActiveCN112161142AChange depthMeet different pressure requirementsEqualizing valvesPipe elementsMechanical engineeringSeawater

The invention aims to provide pipeline water injection valves and a seabed conveying pipeline applying the same. Seawater is directly adopted for injection in the process that the seabed conveying pipeline is installed and sinks into the seabed, the total weight in the transportation, loading and hoisting processes is reduced, and meanwhile, the procedure and cost increase caused by direct liquidinjection in the production process is reduced. The seabed conveying pipeline comprises an outer pipe and an inner pipe, wherein buckle arresting structures are arranged in the length direction of theinner pipe and the outer pipe at intervals, a plurality of mounting holes are formed in the outer pipe, a pipeline water injection valve is fixedly mounted in each mounting hole, and the pipeline water injection valves are used for injecting liquid into an annular space between the inner pipe and the outer pipe; and when the external environment pressure is greater than the design pressure, the pipeline water injection valves are controlled to stop injecting water and seal a water inlet of the outer pipe.

Owner:SHANDONG ZHONGLI HIGH PRESSURE VALVE CO LTD

Pressure-resistant double-layer conveying pipeline

ActiveCN112161121AReduce weightReduce manufacturing costEqualizing valvesPipe elementsStructural engineeringMechanical engineering

The invention aims to provide a pressure-resistant double-layer conveying pipeline. Seawater is directly adopted for filling in the process that the pipeline is installed and sinks into the seabed, the total weight in the transportation and hoisting process is reduced, and meanwhile the working procedure and cost increase caused by direct liquid filling in the production process is reduced. The pressure-resistant double-layer conveying pipeline comprises an inner pipe, an outer pipe and a bending stopping device, wherein the inner pipe is formed by splicing a plurality of inner pipe sections;the outer pipe is formed by splicing a plurality of outer pipe sections; the bending stopping device comprises an outer pipe connecting ring, an inner pipe connecting ring and a supporting body; the outer pipe is further provided with an automatic water filling valve; and the automatic water filling valve controls seawater to be automatically filled into an annular space between the inner pipe andthe outer pipe in the process that the pipeline sinks into the seabed, and therefore the pressure influence of seawater static pressure on the pipeline is relieved.

Owner:东营新达德安新材料科技有限责任公司

A dry process papermaking device and method

InactiveCN105648827BIn line with the development trendWide variety of sourcesPaper-making machinesRaw material divisionMaterials preparationPapermaking

The invention discloses a dry papermaking device which comprises a material preparation device, a forming device, a transferring net, a compacting roller and a drying box, wherein the material preparation device, the forming device, the transferring net, the compacting roller and the drying box are connected in sequence; the forming device comprises a pulp distributor, a pulp flow box and a vacuum net cage; the pulp distributor comprises a pulp distributor body, a Venturi pipeline and a pulp distributor inlet pipe; the material preparation device is connected with the lower end of the pulp distributor body through the pulp distributor inlet pipe and the Venturi pipeline; the upper end of the pulp distributor body is connected with one end of the pulp flow box; the other end of the pulp flow box is arranged on the outer side of an inlet of the vacuum net cage; the outlet end of the vacuum net cage is connected with the transferring net; the vacuum net cage is driven by a variable-speed motor. The dry papermaking method based on the equipment comprises the following steps: material preparation, forming, transferring, compacting, drying and coiling; made paper has the advantages of surface fineness, softness, comfortableness and zero linting and dusting; furthermore, no glue is applied in the papermaking process, so that a large amount of water resources can be saved; therefore, the dry papermaking device and the dry papermaking method are environment-friendly and energy-saving.

Owner:韦周全

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com