Wet etching equipment

A technology of wet etching and equipment, which is applied in the field of microelectronic processing equipment, can solve the problems of reducing equipment utilization rate, affecting product quality, and environmental pollution inside the machine, so as to reduce production costs and improve equipment utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

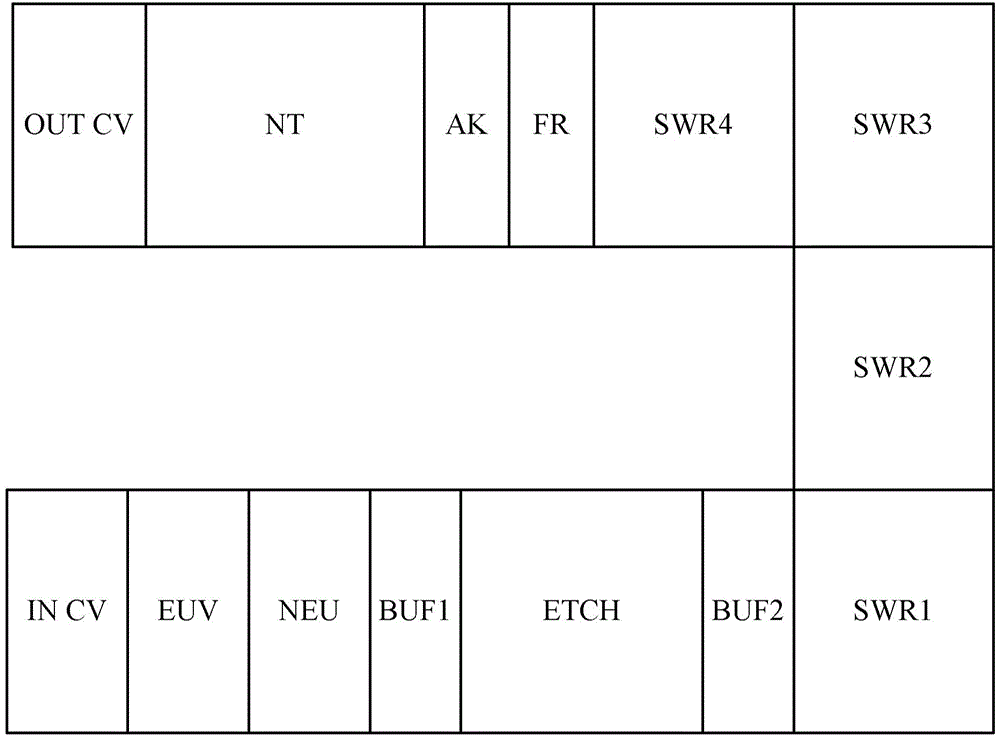

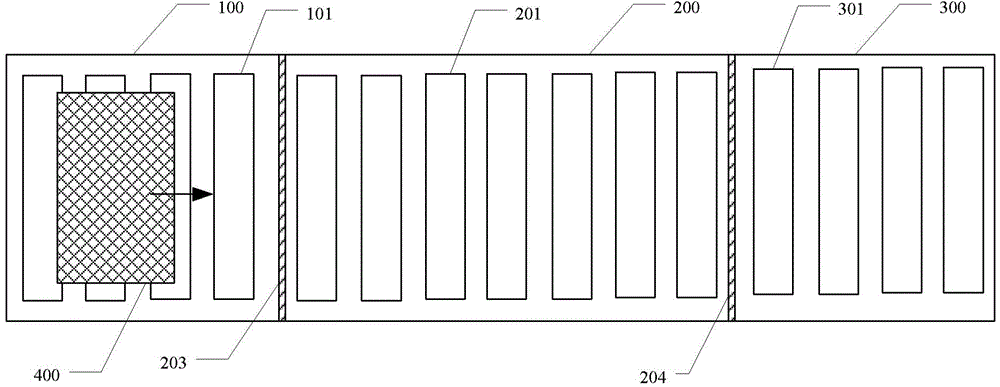

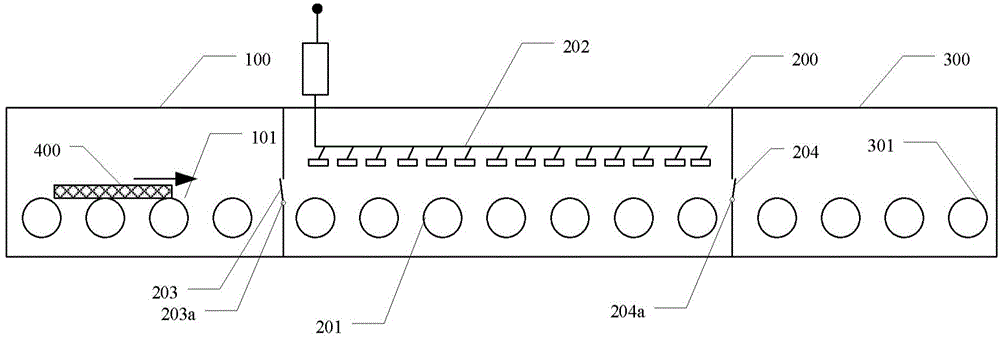

[0045] In an exemplary embodiment of the present invention, a wet etching apparatus is provided. Figure 4A It is a schematic diagram of wet etching equipment according to the first embodiment of the present invention. Figure 4B for Figure 4AA schematic diagram of the position of the front buffer chamber close to the etching chamber in the wet etching equipment shown. like Figure 4A and Figure 4B As shown, the wet etching equipment of this embodiment includes: a front buffer chamber 100 , an etching chamber 200 , a rear buffer chamber 300 and a decrystallization device 500 . The decrystallization device 500 includes: a front spray pipe 501 installed in the front buffer chamber 100 near the etching chamber 200; a rear spray pipe 502 installed in the rear buffer chamber 300 near the etching chamber 200; and Liquid supply pipeline 503. The front spray pipe 501 and the rear spray pipe 502 are supplied with liquid by a liquid supply pipeline 503 for cleaning the etching li...

no. 3 example

[0070] In another embodiment of the present invention, another wet etching device is also provided. The difference between the wet etching equipment of this embodiment and the second embodiment is that: a pipeline is drawn from the waste water discharge pipeline of the first water washing unit SWR1 of the wet etching equipment to supply water to the water tank. The washing flow rate of the first water washing unit SWR1 is relatively large, which can fully meet the water volume of the decrystallization device to remove oxalic acid crystals, and the excess water volume can be discharged from the top of the water tank.

[0071] Other working principles of the wet etching equipment in this embodiment are the same as those in the second embodiment, and will not be repeated here.

[0072] Under normal circumstances, the waste water of the first water washing unit SWR1 is directly discharged. The advantages of this embodiment are: the effect of removing crystals is good, the waste w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com