Dry paper making device and method

A dry-process papermaking and forming device technology, applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve problems such as high water consumption, poor paper quality, environmental pollution, etc., and achieve wide application range, fine surface, and raw material sources broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

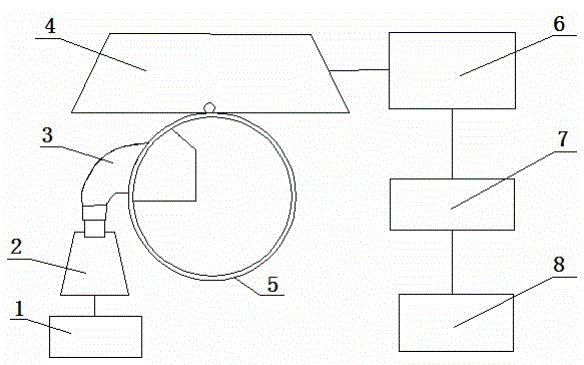

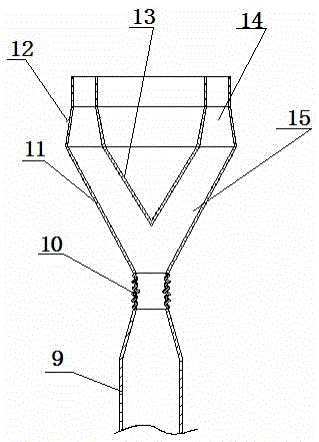

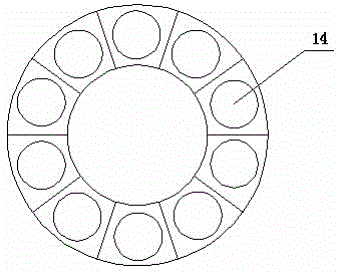

[0030] Such as figure 1 As shown, a dry-laid papermaking device includes a material preparation device 1, a forming device, a transfer wire 4, a compaction roller 6, an oven 7 and a coiler 8, a material preparation device 1, a forming device, a transfer wire 4, and a compaction roller 6 , oven 7 and coiler 8 are connected sequentially, wherein, the molding device includes a slurry distributor 2, a headbox 3 and a vacuum cage 5, combined figure 2 As shown, the slurry distributor 2 includes a slurry distributor body 12, a Venturi pipeline 10 and a slurry distributor inlet pipe 9, and the stock preparation device 1 is connected to the lower end of the slurry distributor body 12 through the slurry distributor inlet pipe 9 and the Venturi pipeline 10, The upper end of the pulp distributor body 12 is connected to one end of the headbox 3, and the other end of the headbox 3 is set outside the entrance of the vacuum cage 5, and the lower part of the headbox 3 can be supported by a fi...

Embodiment 2

[0040] Such as figure 1 As shown, a dry-laid papermaking device includes a material preparation device 1, a forming device, a transfer wire 4, a compaction roller 6, an oven 7 and a coiler 8, a material preparation device 1, a forming device, a transfer wire 4, and a compaction roller 6 , oven 7 and coiler 8 are connected sequentially, wherein, the molding device includes a slurry distributor 2, a headbox 3 and a vacuum cage 5, combined figure 2 As shown, the slurry distributor 2 includes a slurry distributor body 12, a Venturi pipeline 10 and a slurry distributor inlet pipe 9, and the stock preparation device 1 is connected to the lower end of the slurry distributor body 12 through the slurry distributor inlet pipe 9 and the Venturi pipeline 10, The upper end of the pulp distributor body 12 is connected to one end of the headbox 3, and the other end of the headbox 3 is set outside the entrance of the vacuum cage 5, and the lower part of the headbox 3 can be supported by a fi...

Embodiment 3

[0050] Such as figure 1 As shown, a dry-laid papermaking device includes a material preparation device 1, a forming device, a transfer wire 4, a compaction roller 6, an oven 7 and a coiler 8, a material preparation device 1, a forming device, a transfer wire 4, and a compaction roller 6 , oven 7 and coiler 8 are connected sequentially, wherein, the molding device includes a slurry distributor 2, a headbox 3 and a vacuum cage 5, combined figure 2 As shown, the slurry distributor 2 includes a slurry distributor body 12, a Venturi pipeline 10 and a slurry distributor inlet pipe 9, and the stock preparation device 1 is connected to the lower end of the slurry distributor body 12 through the slurry distributor inlet pipe 9 and the Venturi pipeline 10, The upper end of the pulp distributor body 12 is connected to one end of the headbox 3, and the other end of the headbox 3 is set outside the entrance of the vacuum cage 5, and the lower part of the headbox 3 can be supported by a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com