Machine-made sand and application thereof

A technology of machine-made sand and fine crusher, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of concrete volume expansion, high brittleness, and damage to concrete structures, etc., to improve compressive strength and performance Stable and simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the examples, and the examples are only used to illustrate the present invention, but not to limit the present invention in any form.

[0028] Examples and comparative examples

[0029] 1. The main components of ferronickel slag

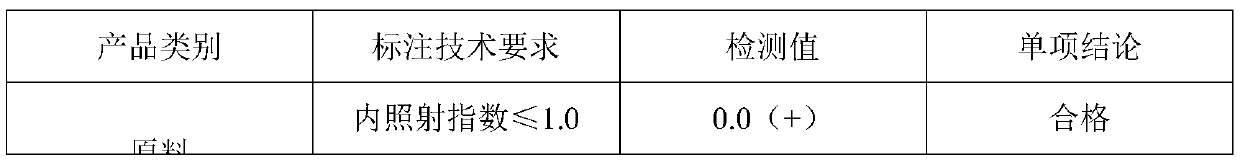

[0030] Table 1 Main components of nickel-iron alloy slag

[0031] main ingredient SiO2 MgO Al2O3 CaO TF other content / % 52.44 26.32 4.76 1.88 12.07 2.53

[0032] From Table 1, we know that the main components of ferronickel slag are: SiO 2 , MgO, Fe 2 o 3 , CaO, Al 2 o 3 , Others in the table are mainly oxides of Mn, Cr, Ti, etc. and a small amount of nickel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com