Sewage conduit cleaning device

A technology for cleaning devices and sewage pipelines, which is applied to water supply devices, cleaning sewage pipelines, waterway systems, etc., can solve the problems of high labor intensity, high cleaning cost and low efficiency in cleaning sewage pipelines, saving labor, production and use costs. low, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

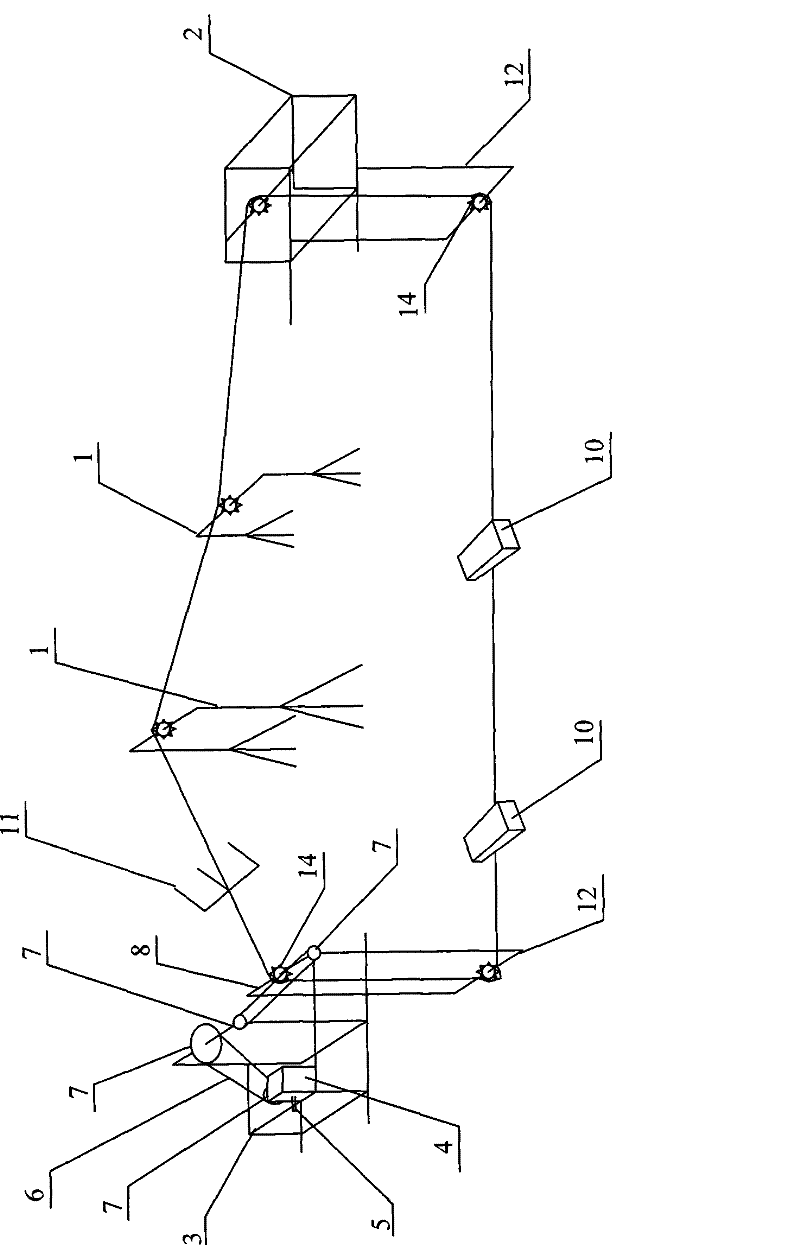

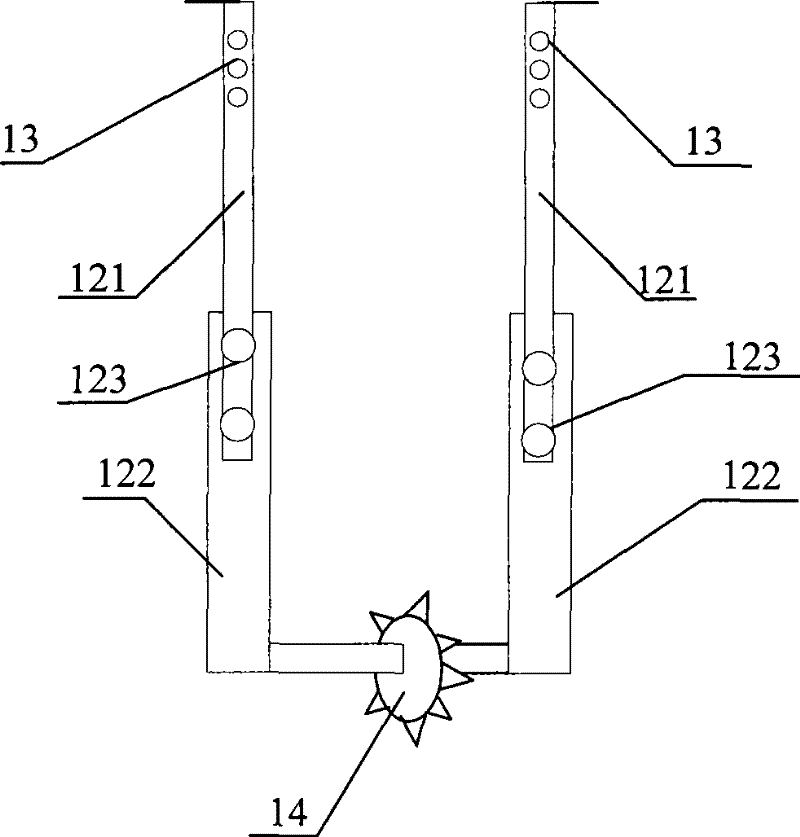

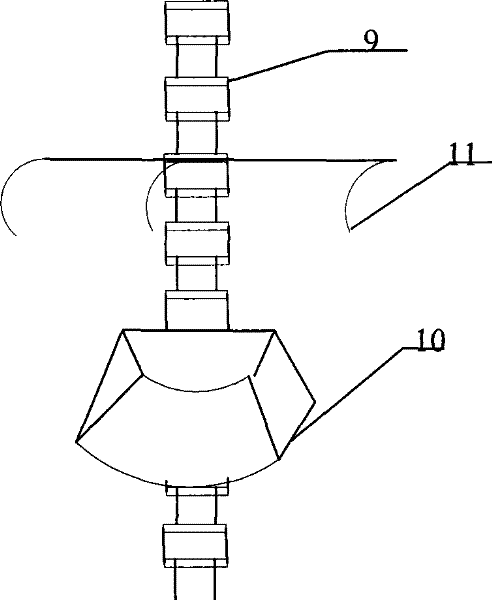

[0020] The relationship between the reference numerals in the accompanying drawings and the indicated components is: 1-ground support frame, 2-attached machine, 3-main engine base, 4-gearbox, 5-input shaft of the gearbox, 6-belt, 7-pulley, 8-drive shaft, 9-chain, 10-mud bucket, 11-rake, 12-underground support frame, 121-upper support frame, 122-lower support frame, 123-fastener, 13-top tight Firmware, 14-sprocket.

[0021] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. The main engine includes a main engine base 3, a gearbox 4, a transmission mechanism and a drive shaft 8. In this embodiment, the transmission mechanism is composed of a belt 6 and a pulley 7, and the main engine base 3 is a frame type The supporting structure of the main engine, the gearbox 3, belt 6, pulley 7 and drive shaft 8 of the main engine are all located on the main engine base 3. The attached machine 2 is composed of a frame-type support body and a sprocket se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com