A high-efficiency powder removal and separation device for machine-made sand for construction

A separation device and machine-made sand technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of harsh working environment, large consumption of water resources, high energy consumption, etc. Good cleanliness, improved working environment and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

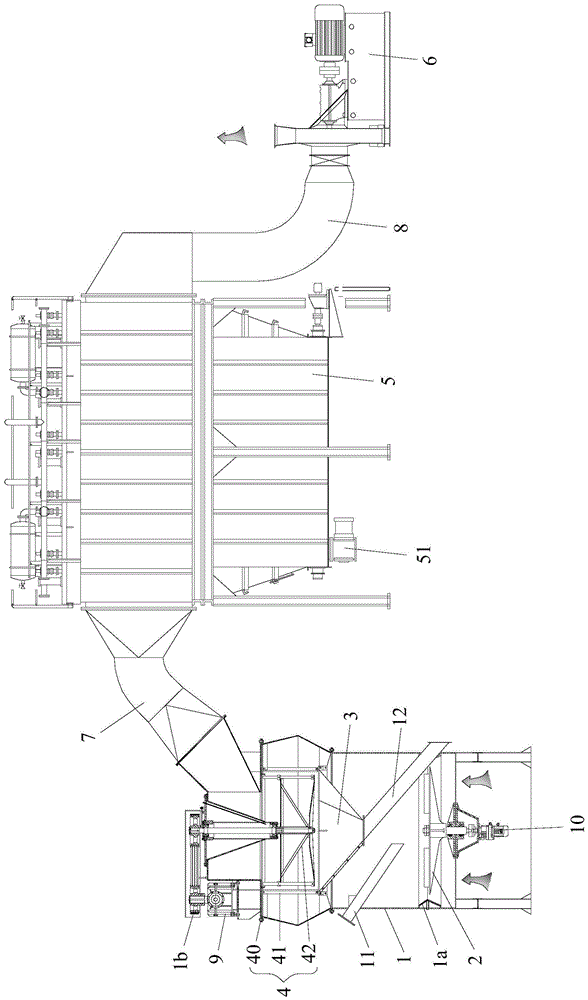

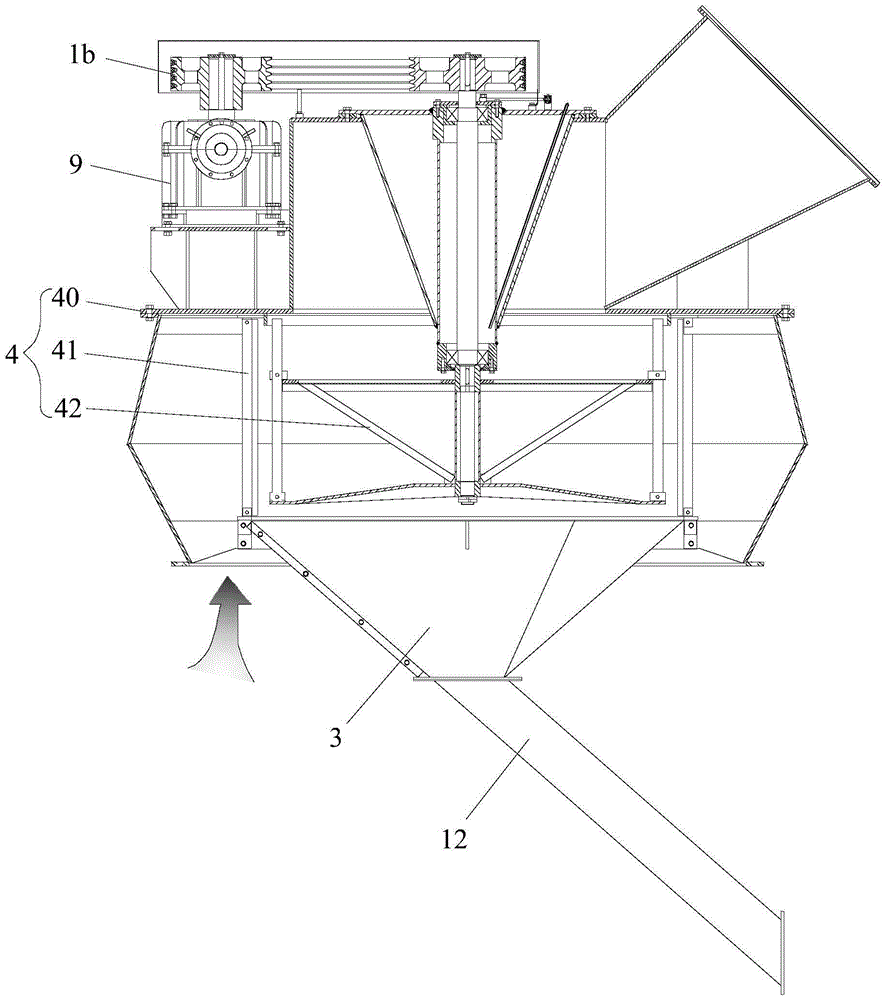

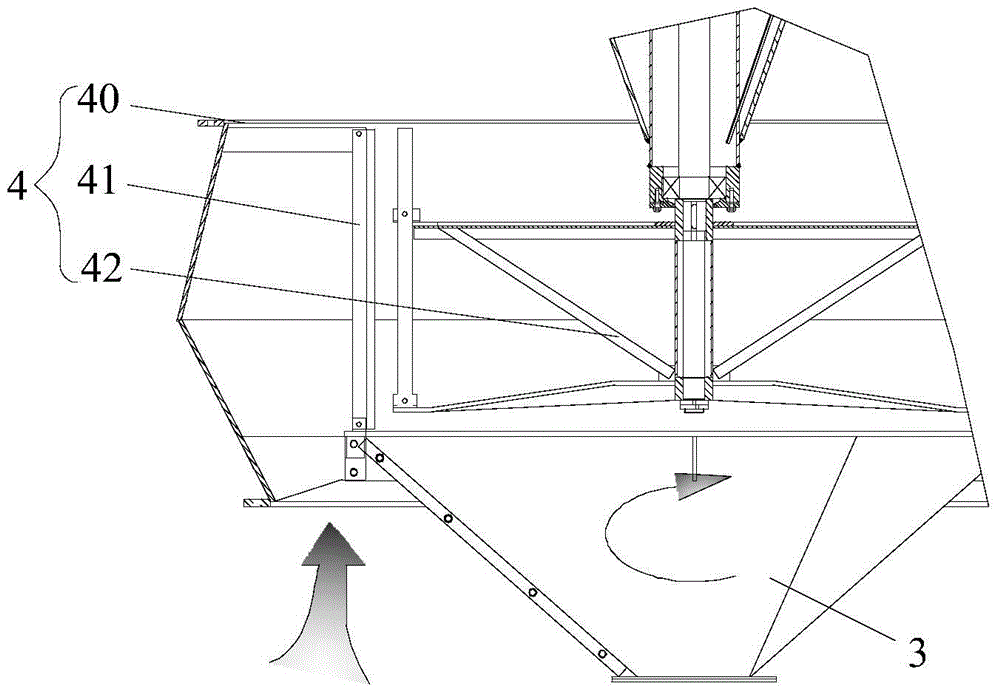

[0024] Please refer to Figure 1-4 , The high-efficiency powder removal and separation device for machine-made sand for construction includes a housing 1, a rotary bulk material tray 2, a sand collecting bucket 3, a sorting device 4, a bag filter 5, a fan 6, a first pipeline 7, a second Two pipelines 8 , a first speed regulating device 9 and a second speed regulating device 10 .

[0025] One side of the shell 1 is provided with a feed channel 11 for feeding primary products containing fine stone powder and mud powder, and the other side is provided with a finished sand discharge channel 12 for discharging large-grain finished sand in the primary product , the feed channel 11 and the finished sand sand outlet channel 12 are both inclined to facilitate feeding and discharging. Both the feed channel 11 and the finished san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com