Assembly asphalt pavement for desert highway and construction method of assembly asphalt pavement

An asphalt pavement and prefabricated technology, which is applied to roads, roads, pavements paved with prefabricated blocks, etc., can solve the problems of low temperature for a long time, high water consumption, and inability to construct, so as to prevent deformation and damage and prolong construction The effect of fast time and construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The assembled asphalt pavement of the desert road of the present invention has been implemented on a certain expressway.

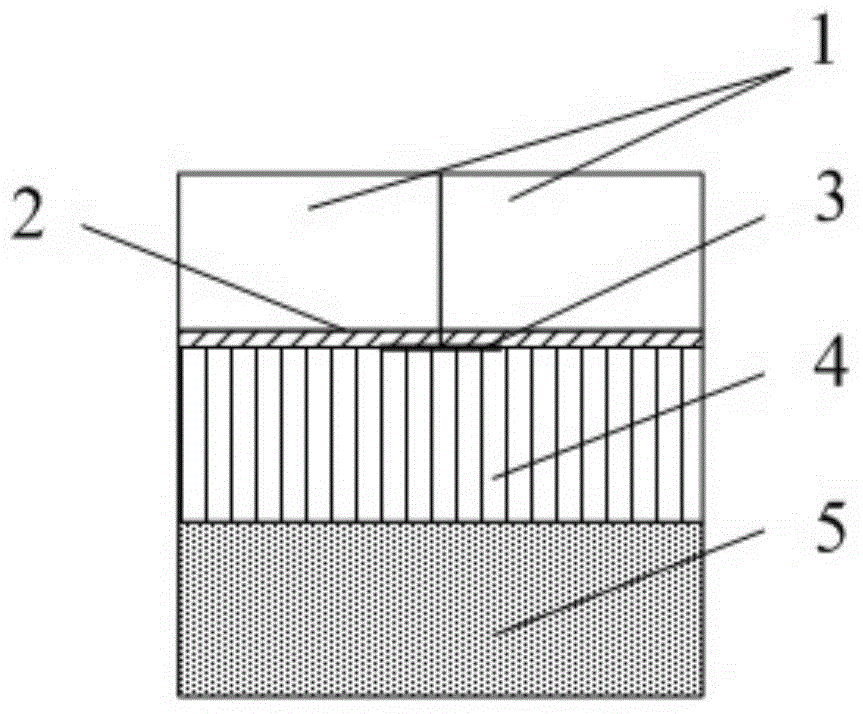

[0040] like figure 1 As shown, the assembled asphalt pavement of the desert road described in this embodiment includes an asphalt pavement prefabricated block composite layer, a crushed stone base 4, and aeolian sand subgrade 5, wherein the asphalt pavement prefabricated block composite layer, crushed stone base 4. The aeolian sand subgrade 5 is laid sequentially from top to bottom according to the layered superposition structure. The composite layer of prefabricated asphalt pavement blocks is formed by assembling and paving a plurality of prefabricated asphalt pavement blocks, and the planar dimensions of each prefabricated asphalt pavement block are: length 5m, width 1m. The thickness of the crushed stone base 4 is 15cm, and a plurality of reinforcement units 3 are laid on its upper surface, which can be geogrid, geotextile or glass fiber cloth, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com