Coal dry-process grading upgrading integrated system and processing method thereof

A dry process and coal technology, applied in grain processing and other directions, can solve the problems of single process, low sorting accuracy, and inability to classify coal with full particle size, and achieve reasonable process, simple process and equipment, and low processing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

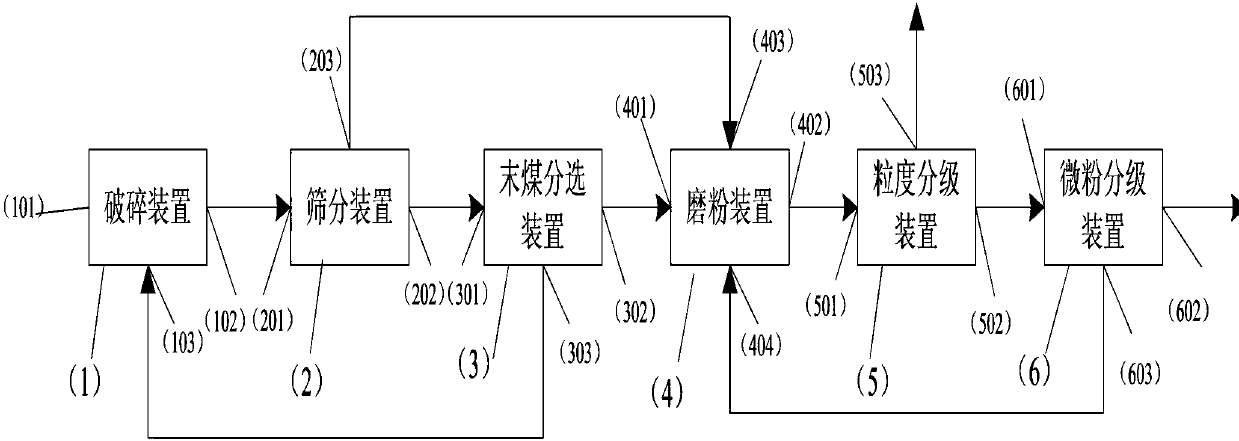

[0051] Such as figure 1 , figure 2 As shown, this embodiment provides an integrated system for classification and quality improvement of coal dry method, the system includes:

[0052] The crushing device (1), the first inlet port (101) of the crushing device, the outlet port (102) of the crushing device, the second inlet port (103) of the crushing device; the screening device (2), the first The inlet port (201), the first outlet port (202) of the screening device, the second outlet port (203) of the screening device; the fine coal separation device (3), the first inlet port of the fine coal separation device ( 301), the first outlet end (302) of the fine coal sorting device, the first inlet port (303) of the fine coal sorting device; the pulverizing device (4), the first inlet port (401) of the pulverizing device, The first outlet port (402) of the milling device, the second inlet port (403) of the milling device, the third inlet port (404) of the milling device; the partic...

Embodiment 2

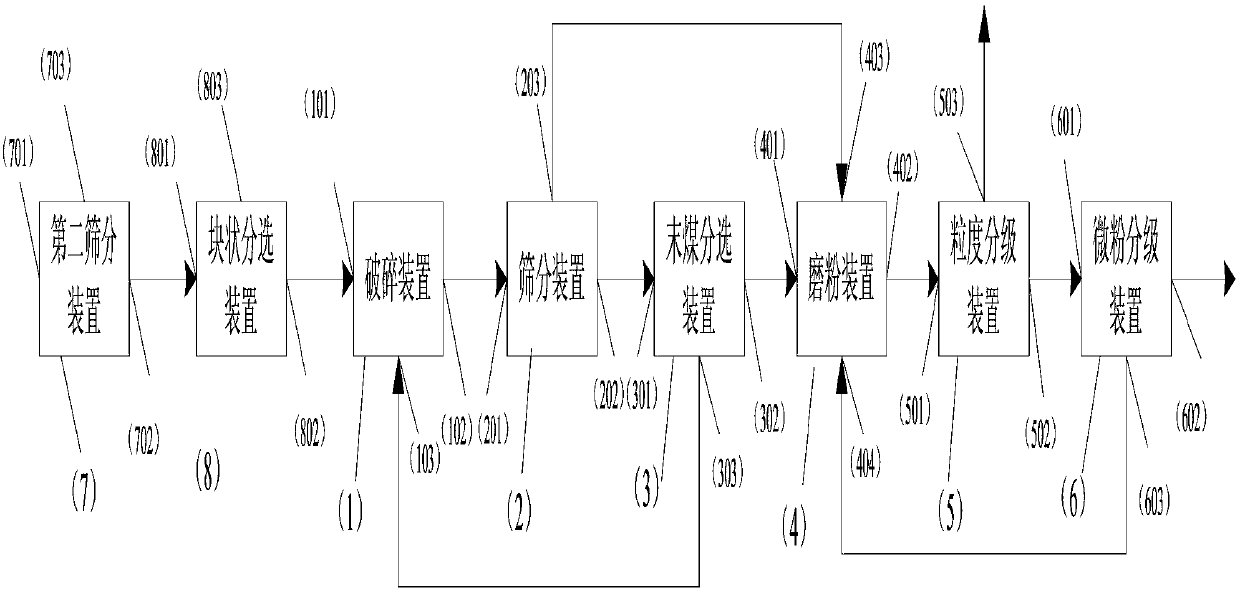

[0056] Such as figure 1 , image 3 As shown, this embodiment provides an integrated system for coal dry classification and quality improvement, the system includes: a crushing device (1), a first inlet port (101) of the crushing device, an outlet port (102) of the crushing device, a crushing device The second inlet port (103) of the device; the screening device (2), the first inlet port (201) of the screening device, the first outlet port (202) of the screening device, the second outlet port of the screening device ( 203); the first inlet end (301) of the fine coal separation device (3), the first inlet end (301) of the fine coal separation device, the first outlet end (302) of the fine coal separation device, the first inlet port of the fine coal separation device (303); the first inlet port (401) of the milling device (4), the first outlet port (402) of the milling device, the second inlet port (403) of the milling device, the milling device The third inlet port (404) of t...

Embodiment 3

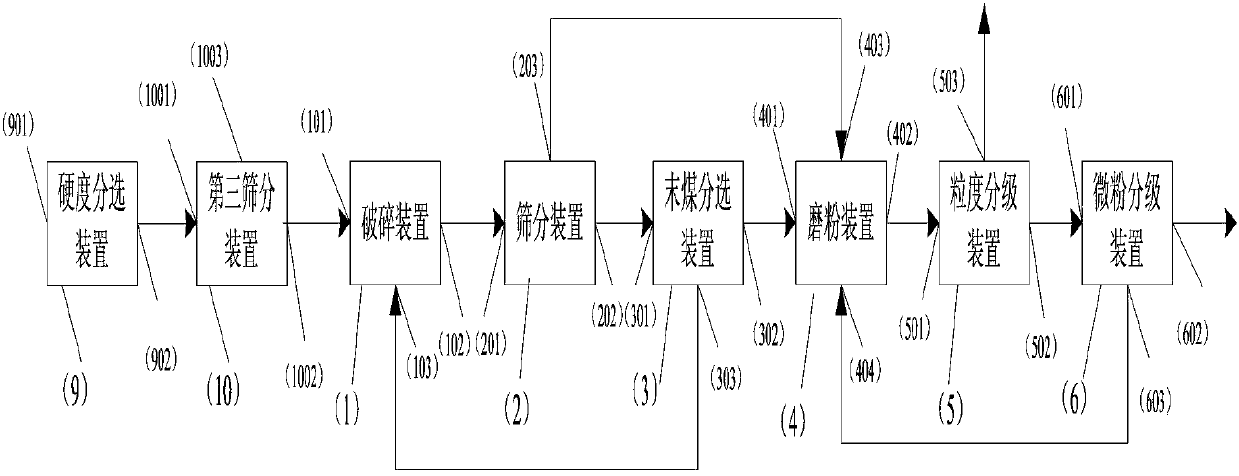

[0060] Such as Figure 4 , Figure 5 As shown, this embodiment provides an integrated processing method for coal dry classification and upgrading, and the method includes the following steps:

[0061] (01) The raw coal is subjected to a second screening to obtain a fine second screening mixture and a coarse second screening mixture.

[0062] In this step, the particle size of the raw coal is less than or equal to 100mm, the ash content is 40%, and the total sulfur is 2%; the particle size of the coarse second screening mixture is greater than 6mm; the particle size of the fine second screening mixture is less than or equal to 6mm ;

[0063] (02) Perform bulk sorting on the coarse second sieved mixture to obtain a first bulk sorted product and a second massive sorted product.

[0064]In this step, the ash content of the first block-shaped sorting object is greater than 80%, and the ash content of the second block-shaped sorting object is 30-50%.

[0065] (03) process the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com