Rotary disc type high-gradient permanent magnetic separator

A magnetic separator and high-gradient technology, which is applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low magnetic field strength, large water consumption, and large footprint, and achieve the improvement of separation recovery rate, The effect of lengthening the sorting time and reducing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

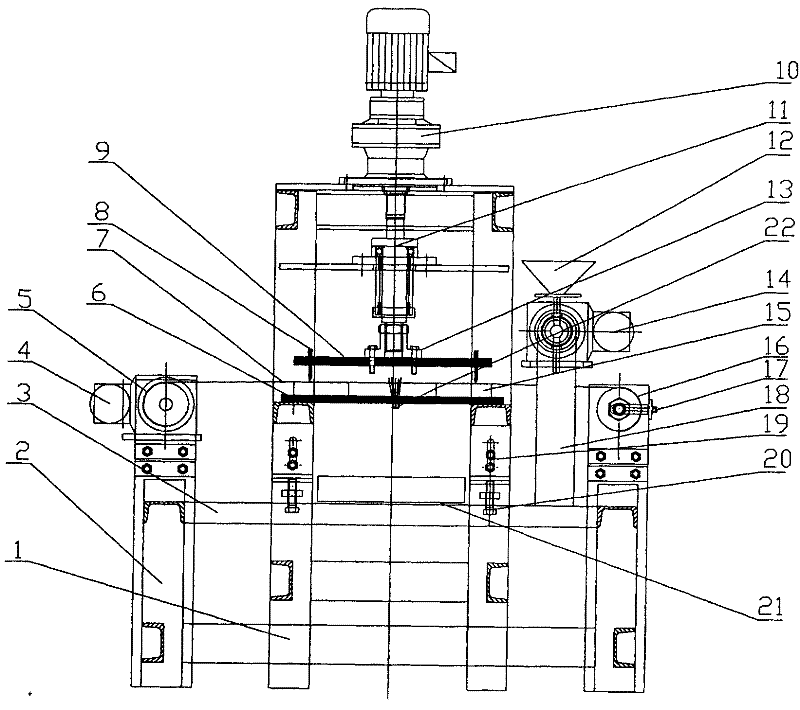

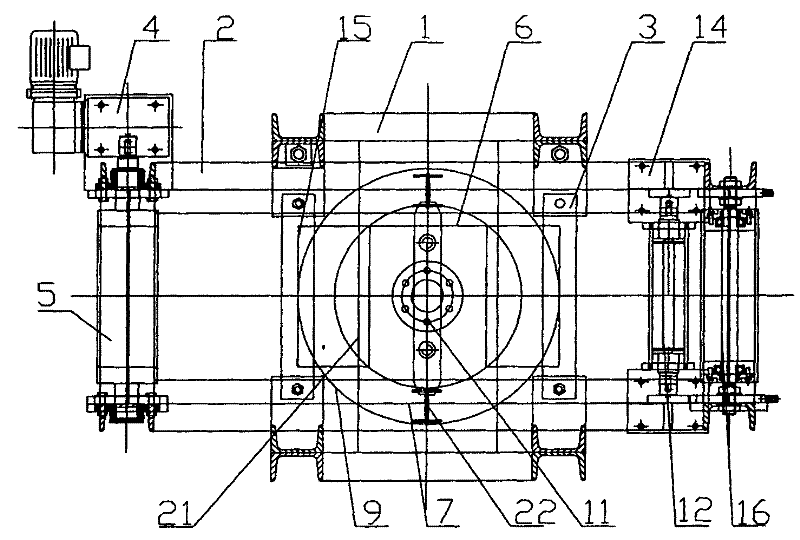

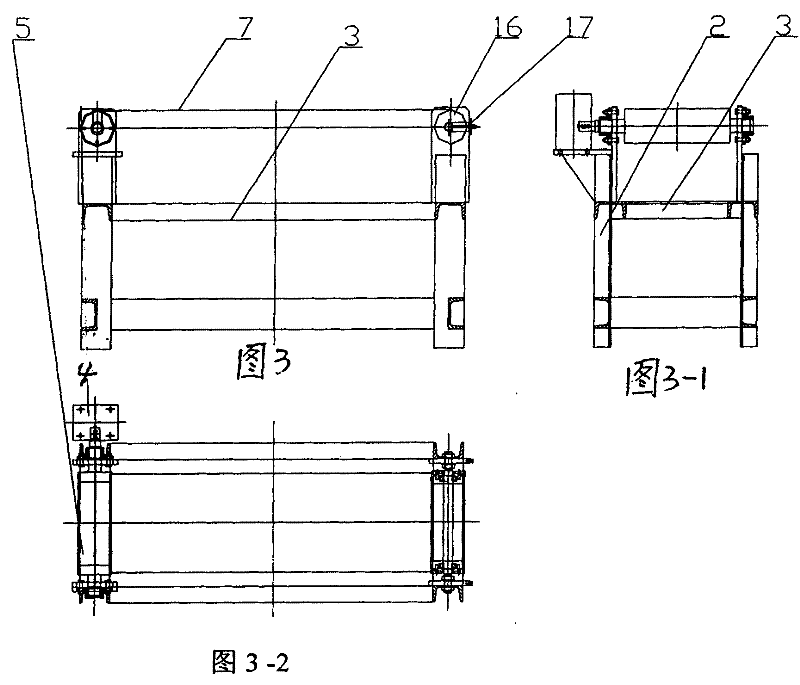

[0037] like figure 1 , 2 As shown, the rotary disc type high-gradient permanent magnet magnetic separator of the present invention comprises drive roll fixed frame 2, is respectively installed in drive roll 5, driven roll 16 at two ends of drive roll fixed frame 2, and by drive roll 5 and slave The conveying belt 7 driven by the moving roller 16; the main body frame 1 arranged across the conveying belt 7 in the middle part of the driving roller fixed frame 2; The lower base frame body and the permanent magnetic steel group support frame installed above the lower base frame body through the limit long head bolt 20 for vertical displacement, the limit long head bolt 20 can be used for permanent magnet steel The vertical height of the group support frame is finely adjusted; on the permanent magnet group support frame, a permanent magnet group 15 and a rotating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com