Production device for machine-made sand for high-performance concrete

A technology of high-performance concrete and production equipment, which is applied in the field of machine-made sand production and manufacturing. It can solve the problems of no secondary treatment and the inability to guarantee the gradation of machine-made sand particles, so as to reduce energy consumption, reduce unilateral water consumption, and improve workability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

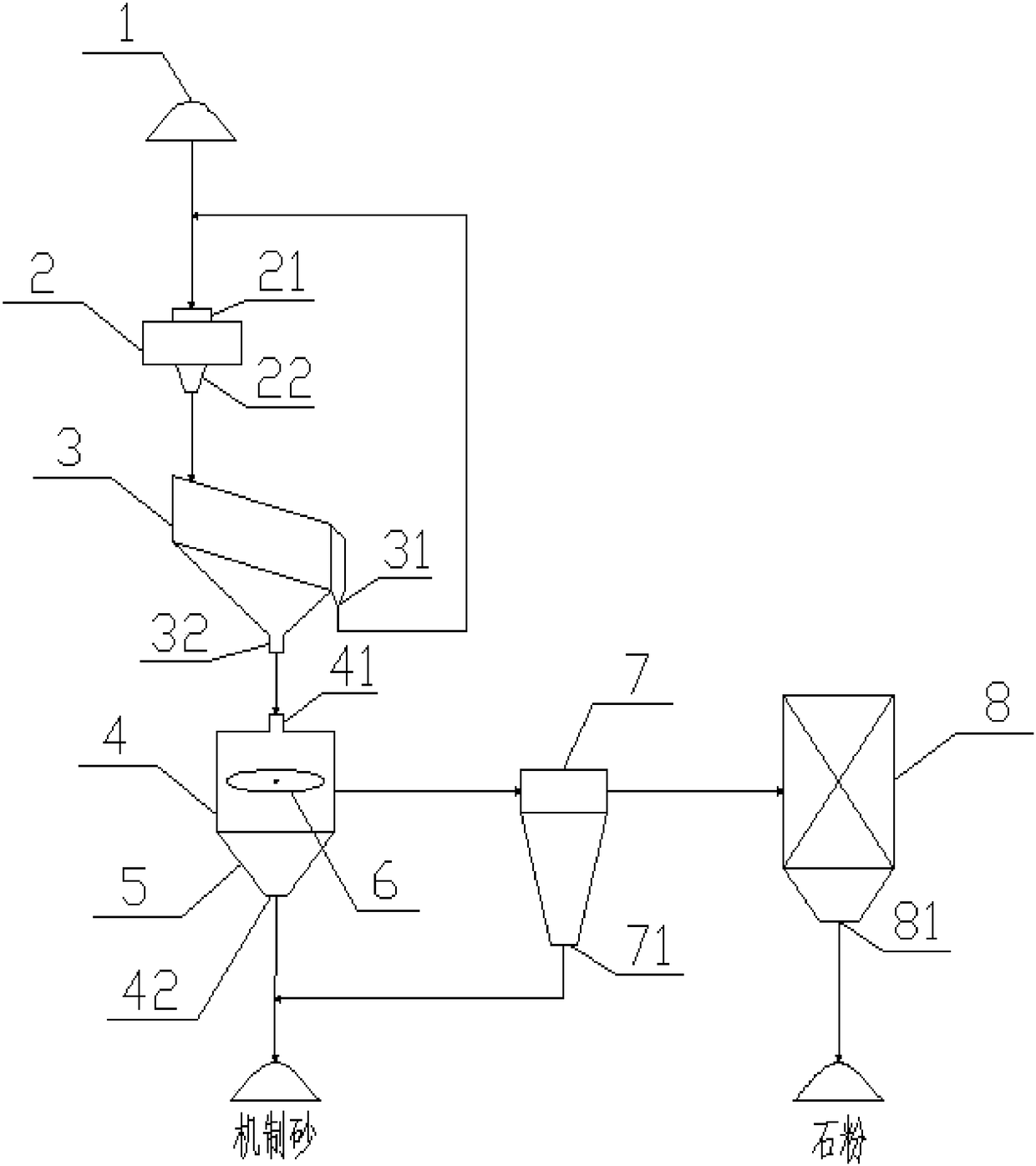

[0020] like figure 1 As shown, a device for producing manufactured sand for high-performance concrete according to the present invention includes a crusher 2, a vibrating screen 3, an air separation device 4, a powder separator 7, and a dust collector 8 connected in sequence; the crusher 2 A crushing inlet 21 and a crushing outlet 22 are provided for crushing the stone material 1; the vibrating screen 3 is connected with the crushing outlet 22 to receive the crushed stone particles of the crusher 2, and to the received stone material The particles are screened. The vibrating screen is provided with a coarse particle discharge port 31 and a fine particle discharge port 32. The screened coarse particles flow out from the coarse particle discharge port 31 on the side of the vibrating screen 3, and the coarse particle discharge port 31 is conveyed through the The equipment is connected to the crushing feed port 21, and the coarse particles are re-crushed in the crusher 2, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com